The Role of Through-Feed Centerless Grinders in Modern Manufacturing

In the fast-evolving landscape of manufacturing, precise and efficient processes are paramount. One of the standout technologies that have made significant contributions to this field is the through-feed centerless grinder. This specialized machinery is essential in various industries, facilitating high-volume production while ensuring exceptional dimensional accuracy and surface finish.

Understanding Through-Feed Centerless Grinding

Through-feed centerless grinding is a process where the workpiece is fed continuously through the grinding wheels. The machine is designed with no fixtures or setups, allowing multiple parts to be ground in a single pass. This is made possible by having two grinding wheels the grinding wheel and the regulating wheel. The grinding wheel removes material while the regulating wheel controls the speed at which the part is fed through the machine, thereby maintaining precision.

Advantages of Through-Feed Centerless Grinders

The advantages of employing through-feed centerless grinders are numerous

1. High Efficiency These grinders are designed for high throughput. Once the setup is complete, they can process a large number of parts in a short amount of time, reducing labor costs and cycle times.

2. Consistent Precision With the ability to maintain tight tolerances, through-feed centerless grinders ensure that every piece produced is identical, which is crucial for parts used in critical applications such as aerospace and medical devices.

4. Versatility Through-feed centerless grinders are capable of processing various shapes and sizes of workpieces. They can accommodate different materials, including metals and plastics, making them ideal for diverse applications across multiple industries.

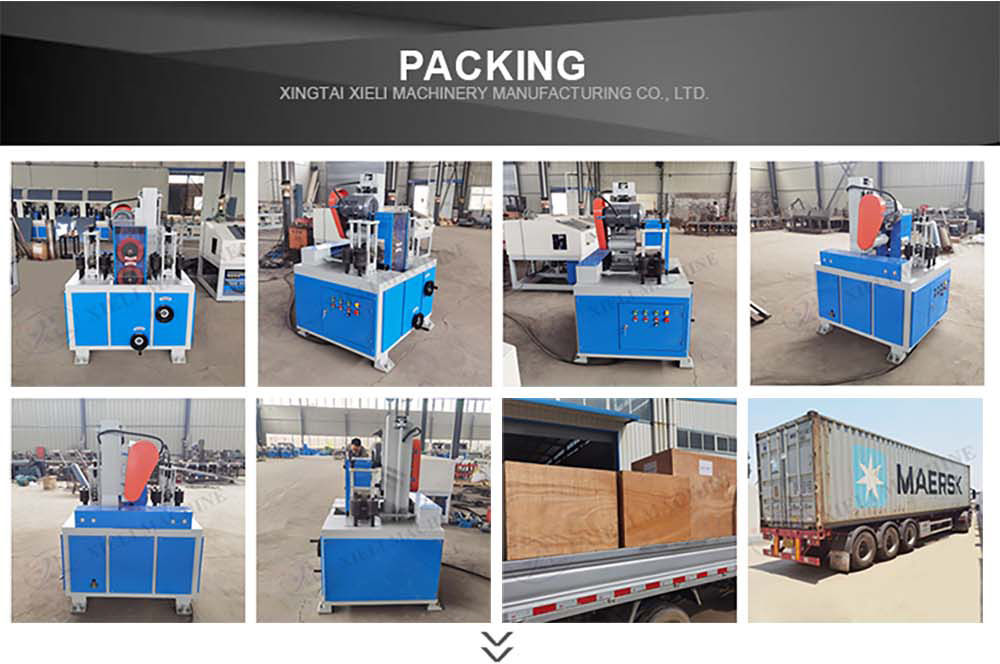

through feed centerless grinder factories

Applications in Various Industries

Through-feed centerless grinders are integral to a wide array of sectors

- Automotive In the automotive industry, these grinders are used for manufacturing shafts, valves, and other components critical to vehicle performance and reliability.

- Aerospace Precision is non-negotiable in aerospace manufacturing. Through-feed centerless grinders produce parts that comply with stringent safety and quality standards.

- Medical In the medical field, where precision components are necessary for devices and instruments, these grinders help in machining surgical equipment and implants, ensuring they meet exact specifications.

- Industrial Equipment Many industrial machines require components that are not only durable but also finely tuned. Through-feed grinding enables manufacturers to meet the demanding requirements of industrial applications.

The Future of Through-Feed Centerless Grinding

As technology advances, the design and functionality of through-feed centerless grinders are also evolving. Automation and integration with Industry 4.0 practices are becoming more common. Smart grinders equipped with IoT technology can monitor processes in real-time, predict maintenance needs, and optimize production efficiency with minimal human intervention. This shift not only enhances performance but also contributes to better quality assurance and operational transparency.

Conclusion

Through-feed centerless grinders play a critical role in modern manufacturing, combining efficiency, precision, and versatility. As various industries continue to prioritize quality and cost-effectiveness, the demand for such grinding technologies is likely to grow. Investing in through-feed centerless grinding solutions will allow manufacturers to remain competitive in an increasingly demanding market, ensuring they meet the high standards required in today’s production environments.