Customized Centerless Grinder Factory Precision Engineering for Your Needs

In the world of manufacturing, precision is paramount. Every process, from the smallest component to the largest assembly, demands accuracy and quality. In this context, centerless grinding has emerged as a vital technique in the production of high-tolerance parts. For those seeking specific solutions tailored to their unique production demands, a customized centerless grinder factory offers a plethora of benefits.

The Concept of Centerless Grinding

Centerless grinding is a machining process that eliminates the need for a machine operator to align the part being worked on. Unlike traditional grinding processes, the workpiece is not fixed between centers; instead, it is supported by a work rest while being rotated by a grinding wheel. This innovative method allows for rapid production of cylindrical parts with excellent dimensional tolerances. The precision achieved through centerless grinding is crucial in various industries, including automotive, aerospace, and medical devices.

Advantages of Customized Solutions

A customized centerless grinder factory stands out not just for its equipment, but for its ability to cater to specific manufacturing needs

. Here are several advantages of utilizing a customized approach to centerless grinding1. Tailored Design Manufacturing processes can vary dramatically from one company to another. Customized centerless grinders can be designed to meet the specific size, shape, and tolerance requirements of the products being manufactured. Whether it’s a large industrial part or a small precision component, a tailored solution ensures that the machinery can handle the unique challenges presented by each project.

2. Enhanced Efficiency Custom machines can be engineered for optimal performance within a specific production environment. With features such as automated loading and unloading, specialized feeding mechanisms, and advanced control systems, manufacturers can increase throughput while reducing cycle times. This not only boosts productivity but also minimizes the risk of human error.

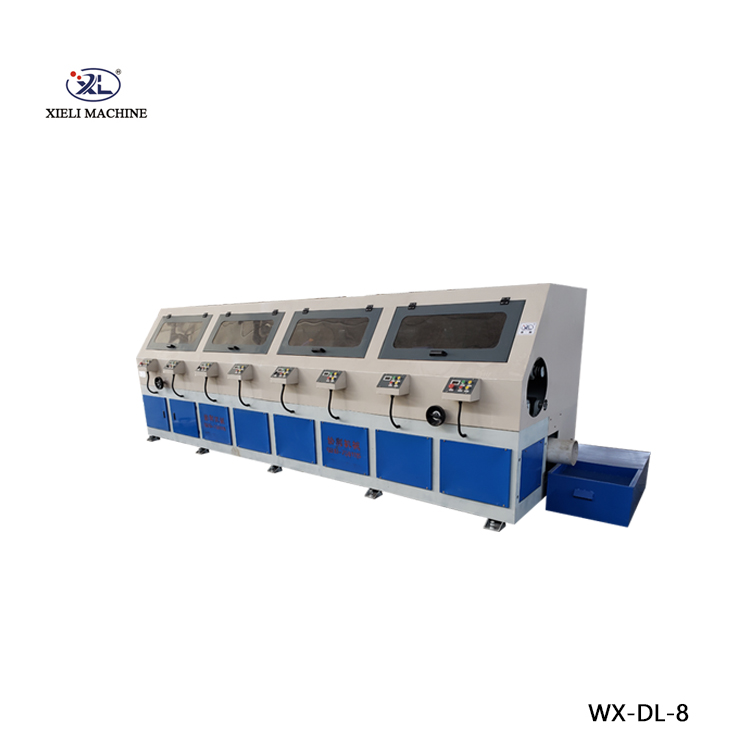

customized centerless grinder factory

3. Robust Quality Control With customization comes the opportunity to integrate advanced quality control measures directly into the grinding process. Automated inspection systems can ensure that every part produced meets the required specifications, reducing waste and rework. This level of quality assurance is particularly essential in industries where safety and reliability are paramount.

4. Flexibility in Production A customized centerless grinder can also offer increased versatility in handling a variety of materials and designs. As market demands shift and new products emerge, having machinery that can be easily adapted saves companies both time and money in the long run.

5. Comprehensive Support and Maintenance When investing in customized machinery, it often comes with the advantage of dedicated support from the manufacturer. This includes training programs for operators, maintenance services, and prompt troubleshooting assistance. Having such support enhances the lifespan of the machinery and ensures consistent production quality.

Innovations in Centerless Grinding Technology

The landscape of centerless grinding technology continues to evolve, with many factories at the forefront of these advancements. Incorporating cutting-edge automation and robotics, these factories are developing machines that not only perform at high speeds but also integrate seamlessly into existing production lines. Furthermore, advancements in software for process monitoring and control allow for real-time adjustments to enhance precision and reduce downtime.

Conclusion

As businesses strive for operational excellence and competitive advantage, the role of customized centerless grinder factories becomes increasingly vital. These factories are not just manufacturers; they are partners in precision engineering, offering tailored solutions that meet the specific needs of their clients. Whether the requirement is for high-volume production or intricate, low-volume specialty parts, a customized approach ensures that the final products meet the highest standards of quality and performance. In an era where every detail counts, the investment in customized centerless grinding technology is not just a choice—it’s a strategic imperative for manufacturers looking to thrive in a competitive landscape.