High-Quality Pipe Polishing Machine Manufacturers Elevating Industrial Standards

In the realms of manufacturing and metalworking, the quality of finished products is often determined by the processes involved in their production. One of the crucial processes that significantly enhance the aesthetic and functional aspects of metal products is pipe polishing. As industries evolve and the demand for high-quality finishes grows, the significance of reliable, high-quality pipe polishing machines has come to the forefront. This article explores the landscape of pipe polishing machine manufacturers and the factors that make some stand out in the industry.

Understanding Pipe Polishing Machines

Pipe polishing machines are specialized equipment designed to enhance the surface finish of metal pipes, ensuring they meet specific aesthetic and performance standards. These machines utilize various techniques, including abrasive polishing, buffing, and electro-polishing, to achieve a smooth, reflective surface on pipes made from stainless steel, aluminum, brass, and other metals. The importance of these machines cannot be overstated, as the quality of pipe polishing affects not only appearance but also resistance to corrosion and overall durability.

The Importance of Quality

When choosing a pipe polishing machine manufacturer, quality is paramount. High-quality machines yield consistent results, reduce waste, and enhance productivity. Manufacturers that prioritize quality often invest in research and development to improve machine designs and functionalities. They utilize robust materials, precision engineering, and advanced technologies to create machines that withstand rigorous industrial applications over time.

Key Features of High-Quality Pipe Polishing Machines

1. Durability High-quality machines are built to last. They are made from high-grade materials that can endure continuous operation without significant wear and tear.

2. Versatility The best manufacturers offer machines that can handle a variety of pipe diameters, lengths, and materials. Versatile machines allow businesses to adapt to different projects without requiring multiple specialized machines.

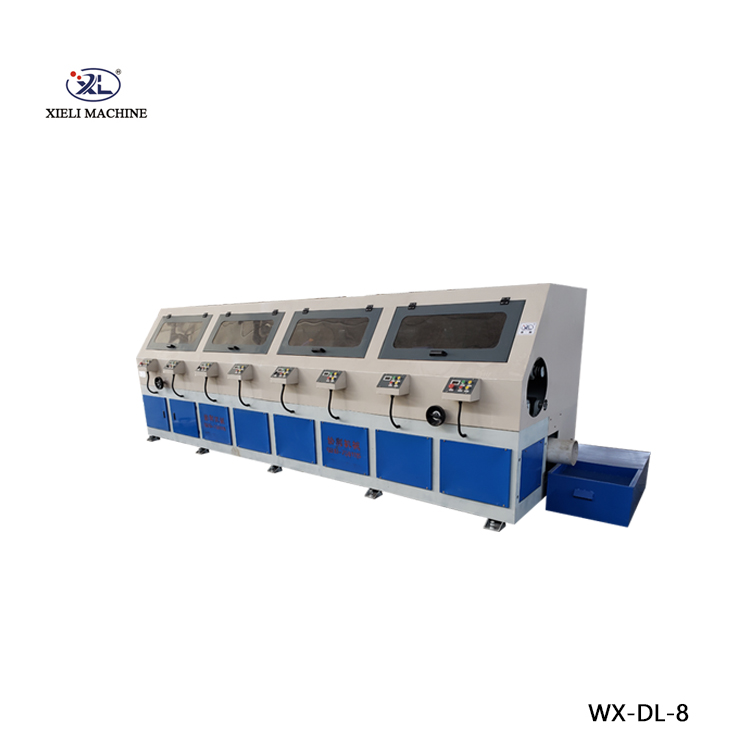

high quality pipe polishing machine manufacturers

3. User-Friendly Design Quality manufacturers focus on ergonomics and user-friendliness in machine design. This includes intuitive controls, easy setup, and accessible maintenance features, which help operators efficiently execute polishing tasks.

4. Precision and Consistency High-end pipe polishing machines provide precise, consistent results across batches. This reliability is crucial for industries that require strict compliance with quality standards.

5. Advanced Technologies Many leading manufacturers incorporate cutting-edge technology into their machines, such as automation and monitoring systems. These features optimize the polishing process, increase efficiency, and enhance the final product's quality.

Leading Manufacturers in the Industry

Several manufacturers have established themselves as leaders in the pipe polishing machine sector. Companies like Baileigh Industrial, Grizzly Industrial, and Kempler Industries are renowned for their innovative designs and high-quality products. They cater to a wide range of industrial applications, from small workshops to large manufacturing plants.

Baileigh Industrial, for instance, is known for its commitment to quality and customer service. Their pipe polishing machines are designed with both performance and longevity in mind, making them a popular choice among professionals. Similarly, Grizzly Industrial offers a diverse range of polishing machines that feature state-of-the-art technology and user-friendly designs, catering to the varying needs of their clients.

Conclusion

In conclusion, the role of high-quality pipe polishing machines in industrial manufacturing cannot be overlooked. As industries continue to demand greater efficiency and precision, the importance of choosing the right manufacturer becomes even more critical. By investing in high-quality machines, businesses not only improve their production capabilities but also enhance the overall quality of their products. With numerous manufacturers in the market, those that prioritize quality, innovation, and customer support will undoubtedly thrive in this competitive landscape. As operations evolve, having the right equipment will serve as a vital component in achieving enduring success in the manufacturing sector.