The Importance of Wholesale Stainless Tube Polishing Machines in Modern Manufacturing

In the rapidly evolving landscape of manufacturing, the demand for high-quality products has never been greater. This demand is particularly evident in industries that rely on stainless steel tubes, such as automotive, aerospace, and construction. One crucial aspect of stainless steel tube production is the polishing process, which not only enhances the aesthetic appeal of the tubes but also improves their corrosion resistance and overall durability. Wholesale stainless tube polishing machines play an essential role in this process, acting as a linchpin in the manufacturing chain.

The Role of Polishing in Stainless Steel Tube Production

Polishing stainless steel tubes serves multiple purposes. Firstly, it removes imperfections and surface irregularities that may have occurred during the manufacturing process. These imperfections, if left unaddressed, can compromise the integrity of the tube, leading to potential failure in demanding applications. Secondly, a polished surface reduces the adherence of contaminants and corrosion agents, significantly extending the lifespan of the product. Last but not least, a well-polished tube enhances the aesthetic appeal of the final product, which is crucial in applications where appearance matters, such as in architectural elements or luxury vehicles.

Features of Wholesale Stainless Tube Polishing Machines

Wholesale stainless tube polishing machines are designed to handle various tube sizes and shapes, making them versatile tools for manufacturers. These machines typically come equipped with advanced technologies that allow for efficient and consistent polishing. They often include features such as adjustable speed controls, automatic feeding systems, and multiple polishing heads, ensuring that they can accommodate different operational demands.

Furthermore, the use of innovative abrasive materials in these machines ensures that the polishing process remains effective while minimizing waste. Some machines even incorporate advanced computer systems that allow for easy programming and integration into automated production lines. This capability not only optimizes the polishing process but also enhances overall productivity.

Cost Efficiency and Bulk Production

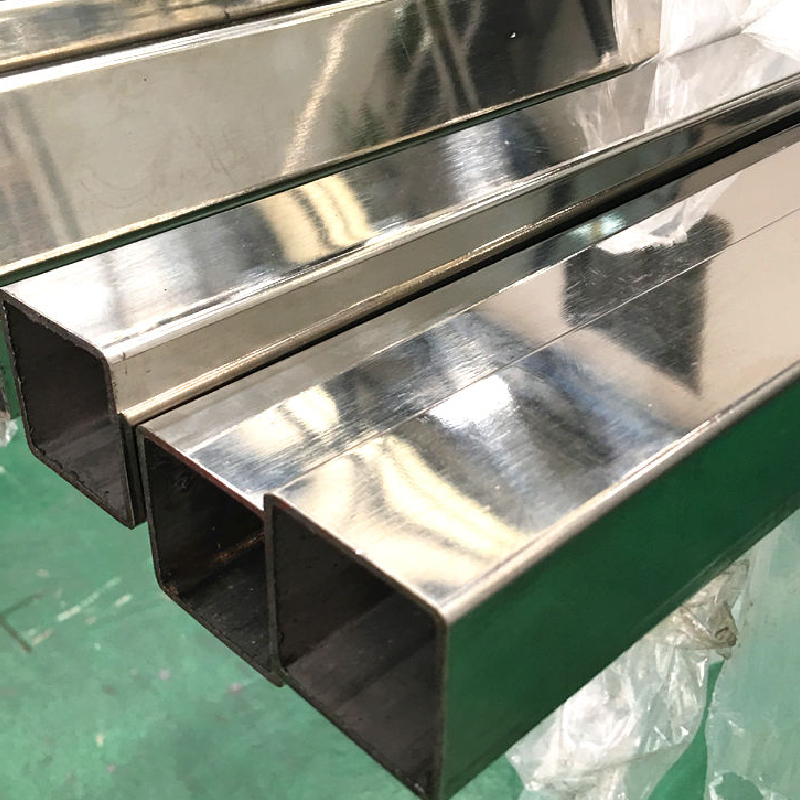

wholesale stainless tube polishing machine

One of the most compelling reasons for businesses to consider wholesale options for stainless tube polishing machines is cost efficiency. Purchasing in bulk often leads to significant savings, which can be reinvested into other areas of the manufacturing process. With the ability to polish large quantities of tubes in a shorter time frame, businesses can increase their output while reducing labor costs.

Moreover, the durability and reliability of high-quality polishing machines mean that manufacturers will incur fewer maintenance costs over time. This long-term investment pays off, especially for those who demand consistent quality and efficiency in their production processes.

Market Trends and Future Prospects

As industries increasingly prioritize sustainability, manufacturers are looking for ways to reduce their environmental impact. Wholesale stainless tube polishing machines that utilize eco-friendly materials and processes are gaining traction. Machines that minimize energy consumption and waste generation are not only appealing to manufacturers for their green credentials but also align with growing regulatory expectations and consumer demands.

The future of wholesale stainless tube polishing machines looks promising, with ongoing advancements in automation and artificial intelligence expected to further enhance their capabilities. Manufacturers who adopt the latest technologies will be better positioned to meet the evolving demands of the market.

Conclusion

In conclusion, wholesale stainless tube polishing machines are integral to modern manufacturing practices. They ensure that stainless steel tubes meet the highest quality standards, enhancing both their performance and appearance. As the manufacturing landscape continues to evolve, investing in advanced polishing technology will be key for businesses looking to thrive in a competitive market. By embracing these machines, manufacturers can improve efficiency, reduce costs, and ultimately produce superior products that meet the rigorous demands of various industries.