Tube Belt Polishing Machine Enhancing Metal Finishing Techniques

In the world of metal processing, achieving a high-quality finish is paramount for both functional and aesthetic purposes. Tube belt polishing machines have emerged as an essential tool in this field, specifically designed to refine the surface of metal tubes and pipes. These machines employ advanced technology and innovative designs to deliver excellent results, enhancing productivity and maintaining high standards of quality.

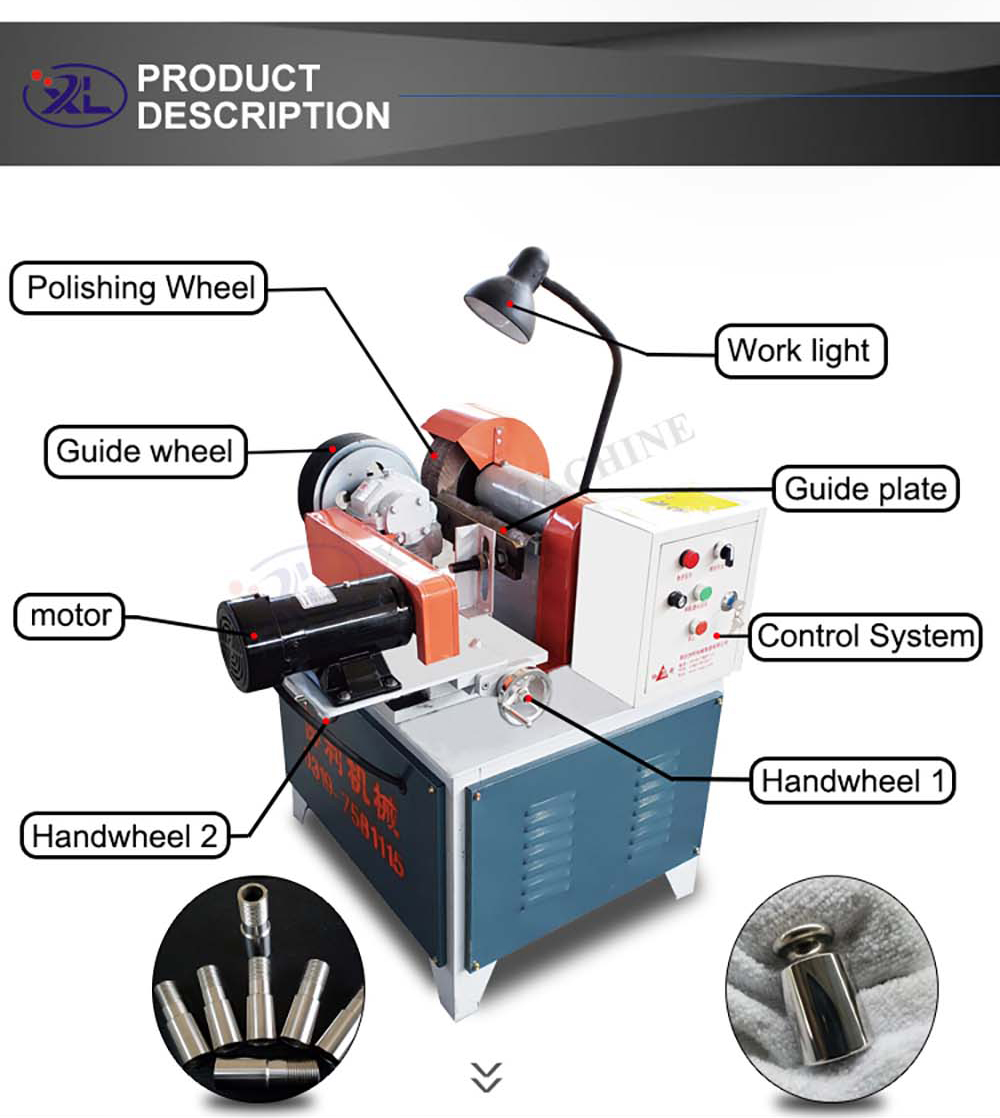

What is a Tube Belt Polishing Machine?

A tube belt polishing machine is a specialized piece of equipment that utilizes abrasive belts to polish the surface of metal tubes. It operates by rotating the tube while applying an abrasive belt against it, effectively removing imperfections, scaling, and oxidation. This process not only improves the surface finish but also prepares the tubes for subsequent operations like plating, coating, or welding.

Key Features and Advantages

1. Versatility Tube belt polishing machines are designed to handle a variety of tube materials, including stainless steel, aluminum, and other alloys. This versatility makes them suitable for a broad range of industries, from automotive to construction and furniture manufacturing.

2. Customizable Settings Modern machines come with adjustable speed settings and interchangeable abrasive belts. Operators can tailor the polishing process to meet specific requirements, ensuring optimal results depending on the material and desired finish.

3. Efficiency These machines significantly improve processing speed compared to manual polishing methods. With the ability to polish multiple tubes in a single pass and achieve consistent results, productivity is greatly enhanced, reducing labor costs and time.

4. Quality of Finish The use of high-quality abrasive belts allows for a smooth and uniform finish, which is crucial for both aesthetic appeal and corrosion resistance. A well-polished tube not only looks better but also performs better in terms of durability and lifespan.

5. User-Friendly Design Many tube belt polishing machines are ergonomically designed for ease of use. Operators can quickly set up the machinery, adjust settings, and monitor the polishing process with minimal effort.

tube belt polishing machine products

Applications of Tube Belt Polishing Machines

Tube belt polishing machines find applications across various sectors

- Automotive Industry In the automotive sector, polished tubes are used for exhaust systems, structural components, and aesthetic details. A high-quality finish is crucial to prevent corrosion and enhance the vehicle’s appearance.

- Construction and Architecture Polished metal tubes are essential in construction for railings, supports, and decorative elements. Their smooth finish is not only visually appealing but also ensures safety and structural integrity.

- Furniture Manufacturing High-end furniture often incorporates polished metal components. Tube polishing machines help manufacturers achieve a refined look that enhances the overall design of their products.

- Food and Beverage Industry In this sector, the cleanliness of surfaces is vital. Polished tubes are easier to clean and less likely to harbor bacteria, making them ideal for plumbing and process piping.

Maintenance and Care

To ensure the longevity and optimal performance of tube belt polishing machines, regular maintenance is essential. Operators should routinely check the abrasive belts for wear and replace them as needed. Additionally, cleaning the machine after use to remove metal shavings and dust will help prevent damage and reduce the risk of corrosion on internal components. Following the manufacturer’s guidelines for maintenance will also contribute to a longer lifespan and better overall performance.

Conclusion

As industries continue to evolve and demand higher quality finishes on metal products, tube belt polishing machines play a crucial role in meeting these needs. With their efficiency, versatility, and ability to deliver superior results, they represent a significant advancement in metal finishing technology. By implementing tube belt polishing machines into their processes, manufacturers can enhance productivity, improve product quality, and maintain a competitive edge in today’s market. Investing in these machines is not just an operational decision but a strategic move toward achieving excellence in metal manufacturing.