Understanding the Price of SS Pipe Polishing Machines A Comprehensive Overview for Manufacturers

In the competitive world of manufacturing, the finishing of products is as crucial as their creation. One essential process that enhances the aesthetic appeal and durability of metal products, particularly stainless steel (SS) pipes, is polishing. For manufacturers looking to invest in SS pipe polishing machines, understanding the price dynamics and the factors that influence these costs is vital. This article explores the various aspects related to the pricing of SS pipe polishing machines and offers insights for potential buyers.

The Importance of SS Pipe Polishing

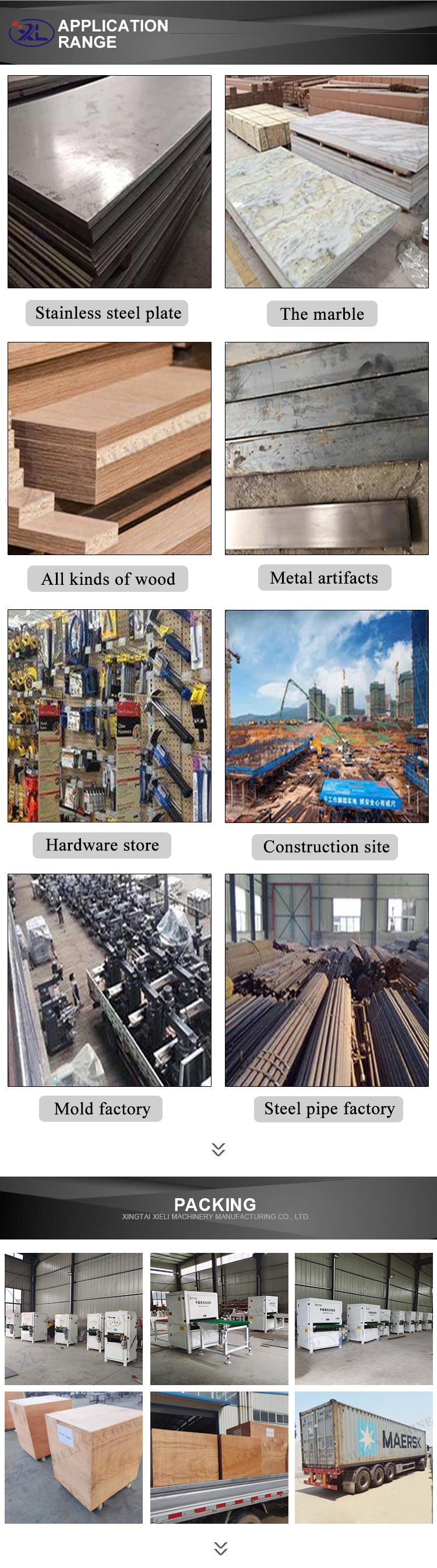

Stainless steel pipes are widely used across various industries, including construction, automotive, food and beverage, and pharmaceuticals. Polishing these pipes not only improves their visual appeal but also enhances their resistance to corrosion and other environmental factors. Therefore, investing in a reliable SS pipe polishing machine is essential for manufacturers who aim to deliver high-quality products that meet industry standards.

Factors Influencing the Price of SS Pipe Polishing Machines

1. Type and Configuration SS pipe polishing machines come in various types, including manual, semi-automatic, and fully automatic systems. The choice of machine plays a significant role in determining the price. Fully automatic machines typically cost more due to their advanced features and increased efficiency, while manual machines are more budget-friendly but require more labor input.

2. Capacity and Size The size and capacity of the polishing machine are crucial factors affecting cost. Larger machines capable of handling bigger pipes or higher volumes of production generally come at a premium price. Manufacturers must assess their production needs to choose a machine that fits their requirements without incurring unnecessary costs.

3. Material and Construction Quality The durability and performance of a polishing machine depend largely on the quality of materials used in its construction. Higher-quality materials, such as robust stainless steel and advanced polymers, enhance machine longevity and effectiveness, but they also escalate the price.

ss pipe polishing machine price manufacturers

4. Technology and Features Modern polishing machines are equipped with various technological advancements, such as programmable logic controllers (PLCs), touch screen interfaces, and automation capabilities. These innovative features can significantly raise the price, but they also improve precision, consistency, and ease of use.

5. Brand Reputation Established manufacturers with a reputation for producing high-quality machinery often charge more due to brand value. While it might be tempting to opt for a cheaper option, investing in a reputable brand can lead to better after-sales support, reliability, and overall satisfaction.

6. Market Demand and Economic Factors The overall demand for SS pipe polishing machines can fluctuate based on market conditions and economic trends. In times of high demand, prices may increase, while economic downturns may lead to price reductions. Manufacturers must stay informed about market trends to make informed purchasing decisions.

Average Pricing

The price range for SS pipe polishing machines can vary widely based on the aforementioned factors. Typically, one can expect to pay anywhere from $3,000 to $50,000 or more. Entry-level machines suitable for small-scale operations may start at the lower end of the spectrum. In contrast, high-capacity, feature-rich machines designed for large-scale production can command professional-level prices.

Conclusion

For manufacturers considering an investment in SS pipe polishing machines, understanding the intricate details surrounding pricing is crucial. By evaluating the factors outlined in this article, businesses can make informed decisions that align with their production goals and budget constraints. In the long run, the right polishing machine can enhance product quality, boost efficiency, and ultimately lead to better profitability. Therefore, careful consideration of features, capacity, brand reputation, and market conditions will enable manufacturers to choose the best machine for their specific needs, ensuring they remain competitive in the ever-evolving manufacturing landscape.