Understanding SS Pipe Polishing Machines Enhancing Aesthetic and Functional Qualities

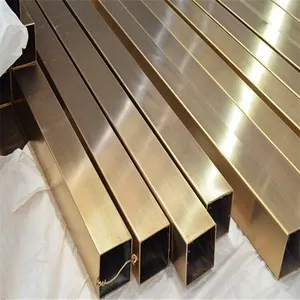

In the manufacturing and processing industries, stainless steel (SS) pipes play a crucial role, serving various applications from plumbing to intricate machinery. However, the appeal and functionality of these pipes can be significantly enhanced through the process of polishing. This is where SS pipe polishing machines come into play, offering a method to achieve a smooth, shiny, and more durable finish on stainless steel pipes.

What is an SS Pipe Polishing Machine?

An SS pipe polishing machine is specialized equipment designed to polish stainless steel pipes to remove surface imperfections, enhance their aesthetic appeal, and improve corrosion resistance. The machine typically utilizes various forms of abrasives, either in the form of sanding belts, wheels, or brushes, to achieve the desired finish. The polishing process not only improves the appearance of the pipes but also helps in preparing them for further treatments like welding or coating.

The Importance of Pipe Polishing

1. Aesthetic Appeal Stainless steel has a natural shine that can be accentuated through polishing. A polished pipe is visually appealing, reflecting light and adding an elegant touch to applications where appearances matter, such as in architectural elements or visible plumbing systems.

2. Corrosion Resistance Polishing stainless steel removes surface contaminants and irregularities. This results in a smoother surface that is less prone to corrosion. The polishing process can seal the micro-pores found on the surface of the steel, thus providing a barrier against moisture and other corrosive agents.

3. Improved Cleanliness For industries like food processing and pharmaceuticals, cleanliness is paramount. A polished finish is easier to clean and disinfect compared to a rough surface, helping to maintain hygiene standards.

4. Enhanced Performance Polished pipes tend to have lower friction coefficients, which can be advantageous in applications involving fluid dynamics. Smoother surfaces facilitate better flow rates and can reduce wear and tear on other components.

Types of SS Pipe Polishing Machines

ss pipe polishing machine

1. Manual Polishing Machines These are simple, user-operated machines that require manual effort to polish pipes. They typically include handheld polishers or grinders fitted with polishing pads. While they can achieve satisfying results, the quality and uniformity of the finish depend heavily on the operator's skill.

2. Automatic Polishing Machines These machines are designed for higher efficiency and consistency. Equipped with automation technology, they can polish several pipes simultaneously while offering adjustable polishing speeds and pressure settings. This type of machine is suitable for large-scale production environments where uniformity and speed are critical.

3. CNC Polishing Machines Computer Numerical Control (CNC) machines take automation a step further. They allow for complex polishing patterns and consistent finishes across batches of pipes. With the ability to program specific polishing parameters, CNC machines offer precision and efficiency, catering to industries that require exacting standards.

Choosing the Right SS Pipe Polishing Machine

When selecting an SS pipe polishing machine, several factors should be considered

- Pipe Size and Shape Ensure that the machine you choose can accommodate the specific dimensions and configurations of the pipes you work with. - Polishing Requirements Different applications may require specific finishes. Identify whether a mirror finish, satin finish, or rough finish is needed.

- Production Volume Determine the scale of your operations. A manual machine might suffice for small workshops, while larger operations would benefit from automated or CNC machines.

- Budget Investment in polishing equipment should align with your overall budget while considering long-term operational efficiency and return on investment.

Conclusion

SS pipe polishing machines are essential tools in maintaining and enhancing the quality of stainless steel pipes across various industries. Whether for aesthetic enhancement or functional improvement, investing in the right polishing equipment can lead to better products, increased customer satisfaction, and adherence to health and safety standards. As the demand for high-quality stainless steel products continues to grow, so too does the importance of proficient pipe polishing practices. In this ever-evolving industrial landscape, keeping abreast of the latest polishing technologies is key to staying competitive and meeting the needs of diverse markets.