Exploring ODM Square Pipe Polishing Machines in India A Comprehensive Overview

In the global manufacturing landscape, the demand for high-quality finishing processes is on the rise, particularly in industries that rely on square pipes. These industries include construction, automotive, aerospace, and furniture, where aesthetics and durability play a critical role. In India, the ODM (Original Design Manufacturer) square pipe polishing machine market is evolving rapidly. This article aims to explore the significance of these machines, their features, and their impact on the Indian manufacturing sector.

Understanding Square Pipe Polishing Machines

Square pipe polishing machines are essential equipment used to enhance the surface finish of square pipes. These machines remove imperfections, burrs, and oxidation, resulting in a shiny, smooth surface that improves both the appearance and corrosion resistance of the pipes. In India, where industrial growth is robust, the demand for polished square pipes has surged, driving manufacturers to invest in advanced polishing technologies.

The ODM Advantage

ODM refers to manufacturers who design and produce products for other companies, allowing clients to sell the goods under their brand name. Indian manufacturers are increasingly turning to ODM square pipe polishing machines for several compelling reasons

1. Customization ODM manufacturers often offer tailored solutions to meet specific requirements. This flexibility allows Indian companies to obtain machines that suit their production needs, whether it's for small-scale operations or large factories.

2. Quality Assurance ODM manufacturers typically maintain rigorous quality control measures, ensuring that the machines meet international standards. This commitment to quality is crucial for companies looking to compete in both domestic and global markets.

3. Cost-Effectiveness By opting for ODM machines, Indian manufacturers can reduce operational costs. These machines tend to be more economical than developing technology in-house, allowing companies to allocate resources to other critical areas of their business.

4. Access to Latest Technologies ODM manufacturers frequently invest in research and development, allowing Indian industries access to cutting-edge polishing technology and innovations that improve production efficiency and product quality.

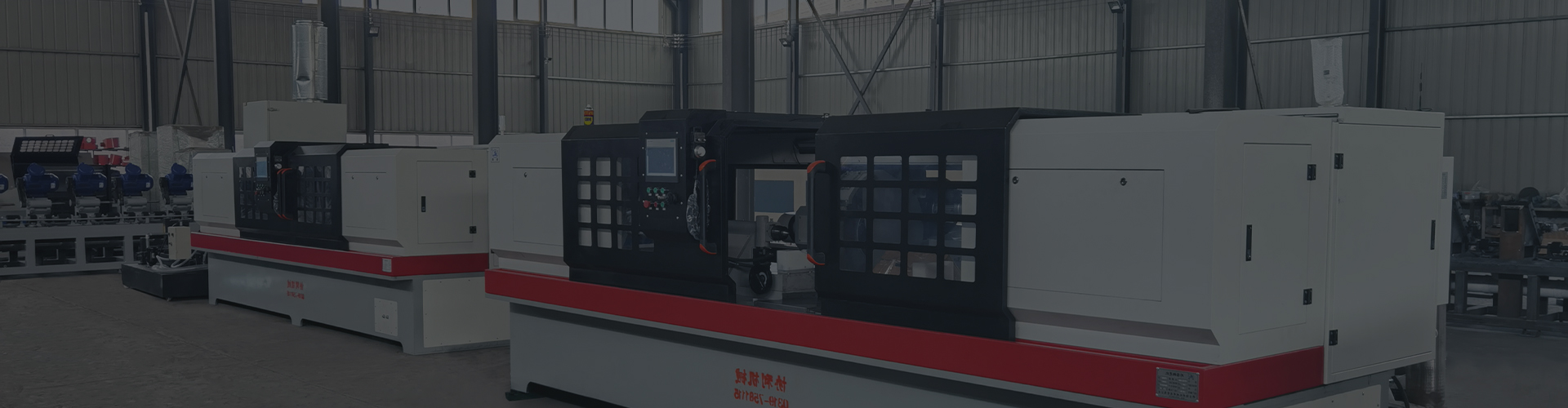

odm square pipe polishing machine india

Key Features of ODM Square Pipe Polishing Machines

The latest ODM square pipe polishing machines come equipped with various features designed to enhance functionality and productivity

- Multi-functional Operations Many machines can perform various tasks, such as polishing, buffing, and deburring, all within one system. This versatility is invaluable for manufacturers who deal with different types of pipes or need multiple finishing processes.

- Automation Advanced polishing machines incorporate automation technologies. CNC (Computer Numerical Control) systems enable precise and consistent polishing, reducing human error and increasing output quality.

- User-Friendly Interfaces Modern machines feature intuitive interfaces, making them easier for operators to manage and operate effectively. Training time is minimized, and productivity is maximized.

- Energy Efficiency With a growing emphasis on sustainability, many ODM polishing machines are designed to be energy-efficient, significantly reducing operational costs and carbon footprints.

Impact on the Indian Manufacturing Sector

The introduction and widespread adoption of ODM square pipe polishing machines have significantly influenced the Indian manufacturing landscape. Enhanced productivity, improved product quality, and reduced operational costs have translated into higher competitiveness within the global market. Furthermore, the advancement of polishing technology fosters innovation across various sectors, driving economic growth and creating job opportunities.

Conclusion

As India continues to develop as a major manufacturing hub, the role of ODM square pipe polishing machines cannot be overstated. They not only streamline production processes but also contribute to the overall quality of finished products. With their numerous advantages, these machines are poised to play a pivotal role in the future of India's industrial landscape. Investing in such technology is not just a trend; it is a necessity for manufacturers aiming to thrive in an increasingly competitive market.