Cincinnati 3 Centerless Grinder A Benchmark in Precision Machining

In the realm of precision machining, few machines hold the esteemed reputation as the Cincinnati 3 Centerless Grinder. Originating from the esteemed manufacturing hub of Cincinnati, Ohio, this piece of equipment has long been a favorite among manufacturers seeking efficiency, accuracy, and reliability in their production processes. Over the years, the Cincinnati 3 Centerless Grinder has set the standard for performance and innovation, making it a staple in various industries, including automotive, aerospace, and manufacturing.

Overview of Centerless Grinding

Centerless grinding is a unique technique used to shape and finish workpieces without the need for a fixed center point. This method allows for the continuous rotation of the part being ground while feed motion is provided by the workpiece itself, held in position by the grinding wheel and a regulating wheel. The Cincinnati 3 Centerless Grinder excels in this domain, delivering not just precision but also speed and consistency.

Key Features of the Cincinnati 3

The Cincinnati 3 boasts a variety of features designed to enhance its performance and ease of use. At the heart of its design is a robust and rigid frame, which minimizes vibrations and optimizes stability while grinding. This characteristic ensures that results are uniform and that the potential for wear on both the machine and the workpieces is minimized.

Another notable aspect of the Cincinnati 3 is its ingenious adjustment system. Operators can easily configure the grinding wheel and regulating wheel to accommodate a range of part sizes and shapes. This adaptability is crucial for businesses that require versatility in their manufacturing processes, as it allows for quick and efficient changes between different tasks without sacrificing precision.

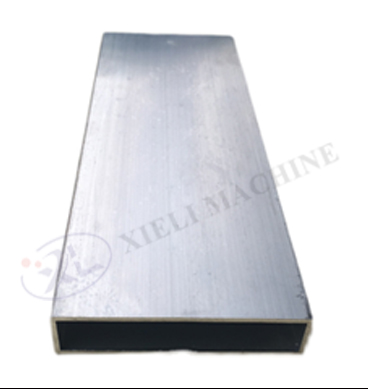

cincinnati 3 centerless grinder product

Furthermore, the Cincinnati 3's control panel is designed with user-friendliness in mind. Intuitive controls and digital displays allow operators to monitor various parameters, ensuring that they can maintain optimal grinding conditions throughout the entire process. This technology not only enhances productivity but also reduces the risk of human error, which can lead to costly flaws in production.

Performance and Applications

Performance is where the Cincinnati 3 truly shines. Capable of achieving exceptional tolerances, this centerless grinder can handle a wide range of materials, including metals, plastics, and composites. Its proficiency makes it particularly valuable in industries where precision is critical. For example, in the automotive sector, it is often used for grinding components such as shafts, bearings, and fuel injectors, where minute imperfections can lead to significant operational issues.

Moreover, the efficiency of the Cincinnati 3 allows for high-volume production runs. Its ability to maintain consistent quality over extended periods makes it a vital asset for manufacturers looking to optimize their productivity while ensuring high-quality output. Organizations that adopt this machinery often report increased throughput and reduced cycle times, which directly contribute to improved profitability.

Conclusion

In conclusion, the Cincinnati 3 Centerless Grinder stands out as a pivotal piece of machinery in the landscape of precision manufacturing. With its robust design, user-friendly features, and exceptional performance capabilities, it has earned its place as a trusted tool in various high-stakes industries. As manufacturers continue to seek solutions that not only enhance efficiency but also ensure superior quality, the Cincinnati 3 remains an enduring symbol of excellence in centerless grinding technology. For any company striving for precision and reliability in their production processes, investing in a Cincinnati 3 Centerless Grinder represents a strategic decision that yields long-term benefits.