Centerless Grinder Suppliers An Essential Resource for Precision Engineering

In the world of precision engineering, centerless grinding plays a critical role. This process is essential for creating components with tight tolerances and superior finishes, making it a crucial operation in various industries, including automotive, aerospace, medical, and manufacturing. Given the importance of this process, finding reliable centerless grinder suppliers is key for companies looking to enhance their production capabilities.

Understanding Centerless Grinding

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece. Unlike traditional grinding methods, where the workpiece is held between two centers, centerless grinding utilizes a different setup. The workpiece is supported by a work rest and rotated between a grinding wheel and a regulating wheel. This design allows for continuous production since the workpiece can be fed quickly through the machine without the need for additional setup time.

The Importance of Quality Suppliers

Quality centerless grinder suppliers are essential for businesses that rely on this technology. A reputable supplier will offer machines designed for efficiency, precision, and durability. When looking for a supplier, it's important to consider several factors

1. Machine Specifications Different applications require different types of centerless grinders. Suppliers should provide a range of options, including in-feed, through-feed, and multi-axis models. Checking specifications such as wheel size, motor power, and adjustable features is crucial to match the machine to your specific needs.

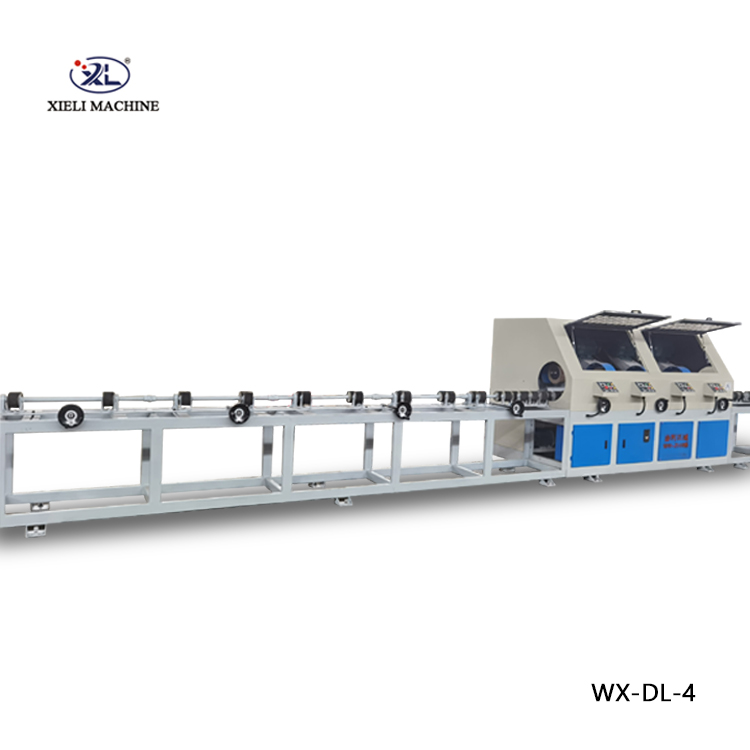

centerless grinder suppliers supplier

2. After-Sales Support A strong relationship with a supplier goes beyond the initial sale. Excellent after-sales support, including maintenance services, training programs, and troubleshooting assistance, ensures that your centerless grinder continues to perform at peak efficiency. Suppliers who provide comprehensive support help reduce downtime and extend the lifespan of your machinery.

3. Industry Reputation Suppliers with a proven track record in the industry can often provide the best recommendations based on real customer experiences. Look for testimonials or case studies that highlight their machines’ performance in various applications.

4. Customization Options As businesses evolve, so do their machining needs. Suppliers that offer customization options for their centerless grinders can provide valuable adaptability for changing production requirements. This can include specialized fixtures, tooling, or software integration to improve productivity.

5. Technological Advancements The manufacturing industry is continuously evolving with technological advancements, including automation, IoT, and AI. Suppliers who incorporate these technologies into their centerless grinding machines can offer enhanced performance and efficiency, setting your operations apart from the competition.

Conclusion

Selecting the right centerless grinder suppliers involves thorough research and consideration of various factors. By focusing on quality, support, reputation, customization, and technology, businesses can significantly improve their machining efficiencies and product quality. In a competitive market, investing in reliable centerless grinders and strong supplier relationships can lead to enhanced productivity and a sustainable advantage. As industries continue to demand precision and quality, the role of competent centerless grinder suppliers will remain pivotal in driving innovation and success.