The Role of Centerless Grinder Machines in Global Manufacturing

Centerless grinder machines have become indispensable tools in modern manufacturing, particularly for industries that require high precision and efficiency in machining processes. Their unique design allows for the grinding of workpieces without the need for a complex setup, making them a preferred choice for many manufacturers in various sectors, including automotive, aerospace, and medical device production.

What is a Centerless Grinder?

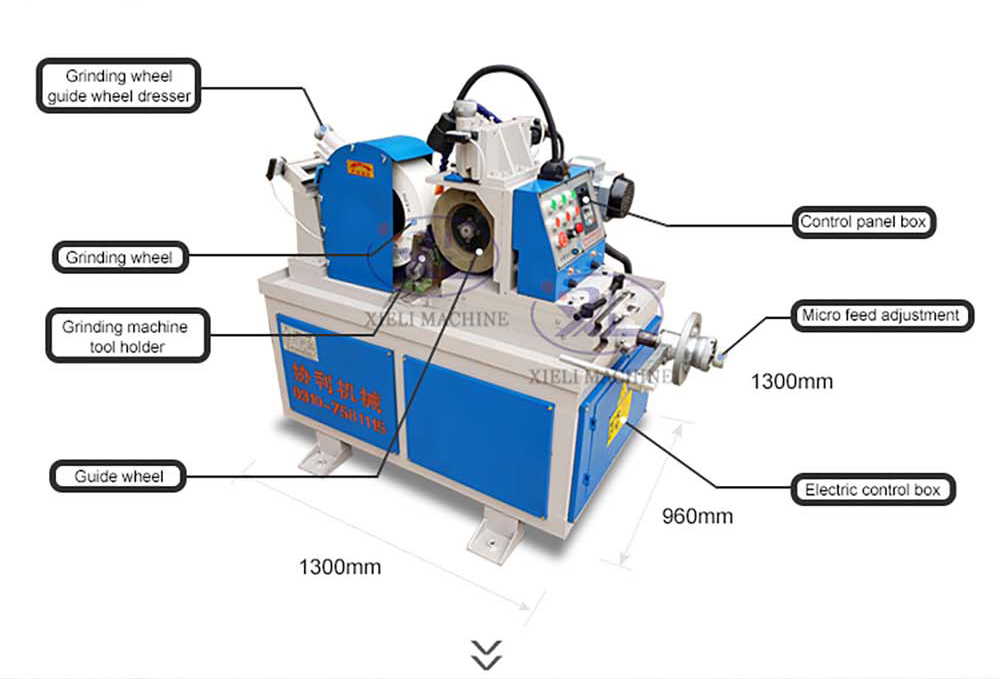

A centerless grinder is a type of grinding machine that uses a rotating grinding wheel to remove material from a workpiece. Unlike traditional grinders, centerless grinders do not hold the workpiece between two centers. Instead, the workpiece is supported on a rotating wheel and held in place by a work rest blade and a regulating wheel. This innovative design allows for the continuous feeding of materials, enabling high-speed production and consistent results.

Advantages of Centerless Grinding

Centerless grinding offers several advantages over conventional grinding methods. One of the primary benefits is the ability to grind long workpieces with minimal set-up time. This feature makes it ideal for high-volume production runs, where efficiency and speed are critical. Additionally, centerless grinders are capable of achieving tight tolerances and superior surface finishes, which are essential for components used in precision engineering applications.

centerless grinder machines exporters

Another significant advantage is the flexibility of the machine. Centerless grinders can handle various materials, including metals, plastics, and ceramics. This versatility makes them suitable for diverse applications, from grinding cylindrical components to intricate shapes. Furthermore, the machine's design minimizes the risk of part damage, as there are no clamping forces on the workpiece, reducing the likelihood of distortion.

The Global Market for Centerless Grinder Machines

As industries across the globe continue to evolve and expand, the demand for high-quality machining tools, such as centerless grinders, has grown exponentially. Exporters of centerless grinder machines are now catering to a worldwide market, providing advanced models with cutting-edge technology and enhanced features. Countries known for their engineering expertise, such as Germany, Japan, and the United States, have become key players in manufacturing and exporting these essential machines.

In recent years, the rise of automation and smart manufacturing has also influenced the market for centerless grinders. Manufacturers are increasingly seeking machines that incorporate advanced features like CNC controls, predictive maintenance, and real-time monitoring systems. This trend has led to the development of sophisticated centerless grinder machines that not only meet current machining standards but also anticipate future industry needs.

Conclusion

Centerless grinder machines play a pivotal role in the manufacturing landscape, providing essential capabilities for producing precision components quickly and efficiently. As the global market for these machines continues to grow, exporters are positioned to meet the demands of increasingly complex manufacturing processes. Innovations in technology will likely drive further advancements in centerless grinding, ensuring that this crucial tool remains at the forefront of industrial production. Ultimately, the emphasis on quality and efficiency in modern manufacturing will keep centerless grinder machines in high demand, benefitting both suppliers and manufacturers alike.