The Best Tube Polishing Machine A Comprehensive Guide

When it comes to finishing metal components, especially in industries like automotive, aerospace, and manufacturing, the importance of a high-quality tube polishing machine cannot be overstated. These machines are designed to deliver a smooth and shiny finish to tube surfaces, enhancing both aesthetics and corrosion resistance. In this article, we will explore the best tube polishing machines available, their features, applications, and tips for selecting the right one for your needs.

What is a Tube Polishing Machine?

A tube polishing machine is a specialized piece of equipment that smooths and polishes the exterior surfaces of metal tubes and pipes. These machines use various mechanical methods such as abrasive finishing, buffing, and polishing, often employing a combination of belts, discs, and brushes. Depending on the application, they can handle different materials such as stainless steel, aluminum, brass, and more.

Importance of Tube Polishing

1. Aesthetics A polished tube looks more professional and visually appealing, making it vital for industries where appearance matters, such as furniture design and automotive parts.

2. Corrosion Resistance Polishing reduces the risk of corrosion by cleaning surfaces and minimizing the presence of contaminants that could lead to rust and deterioration.

3. Performance Smooth surfaces can enhance fluid flow in pipes and tubes, which is crucial for applications in HVAC systems and automotive fuel lines.

4. Durability A well-polished surface can lead to longer-lasting components by reducing wear and tear during usage.

Features of the Best Tube Polishing Machines

When searching for the best tube polishing machine, consider the following features

1. Versatility The machine should be capable of handling various tube sizes and materials. Some machines come with adjustable fixtures or can process multiple diameters.

best tube polishing machine

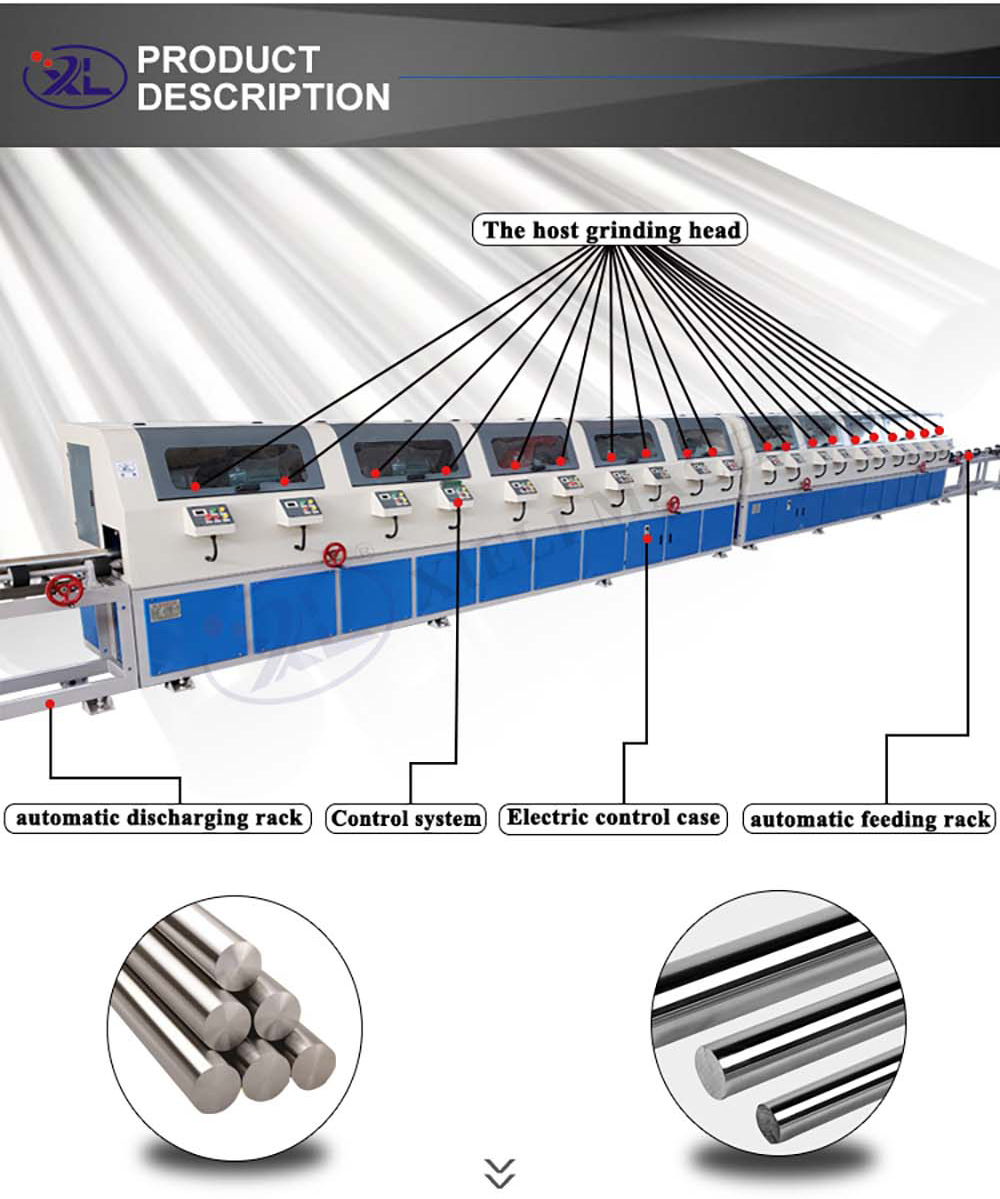

3. Automation Many modern machines feature automation capabilities that enhance efficiency and consistency. Automatic speed control and programmable cycles can significantly reduce manual labor.

4. Ease of Use User-friendly controls and intuitive designs are essential. Machines equipped with digital displays and touch controls are easier to operate.

5. Safety Features Given that polishing involves the use of high-speed moving parts, safety mechanisms such as emergency stop buttons and guards are critical.

Top Tube Polishing Machines

1. CNC Tube Polisher This advanced machine uses computer numerical control (CNC) technology to automate the polishing process. It provides high precision and can be programmed for various polishing specifications, making it ideal for mass production.

2. Belt Tube Polisher A popular choice for many workshops, belt tube polishers utilize abrasive belts to achieve a polished finish. They are versatile, and models with variable speed settings allow for custom polishing according to the material.

3. Brush Tube Polisher This type is excellent for achieving a uniform finish on both straight and curved surfaces. It uses rotating brushes and can be perfect for softer metals that require gentle handling.

4. Robotic Polishing Systems These machines can replicate human movement and are excellent for complex shapes and hard-to-reach areas. They provide consistent finishes and reduce production time significantly.

Selecting the Right Machine

When choosing the best tube polishing machine, assess your specific needs, such as

- The types and sizes of tubes you will be polishing. - The volume of production to determine whether you need a manual, semi-automatic, or fully automatic machine. - Your budget and long-term investment considerations.

Conclusion

In conclusion, investing in a quality tube polishing machine can significantly enhance the efficiency, appearance, and durability of your metal tubes. By considering the features and types of machines available, along with your specific needs, you can find the ideal solution for your polishing requirements. Whether you are in manufacturing, automotive, or any field that requires polished tubes, the right machine can make all the difference in your production process.