The ODM Cincinnati Twin Grip Centerless Grinder An Engineering Marvel

In the world of precision engineering, the importance of reliable and efficient grinding machinery cannot be underestimated. Among the many advanced designs available, the ODM Cincinnati Twin Grip Centerless Grinder stands out as a remarkable solution for high-precision grinding tasks. This machine is engineered to meet the demands of modern manufacturing environments, ensuring superior performance and exceptional accuracy.

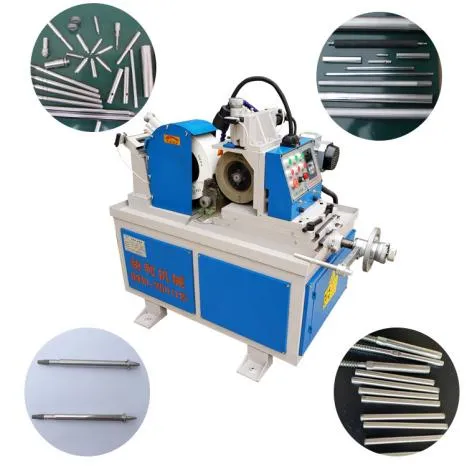

The Twin Grip Centerless Grinder is built on the principle of centerless grinding, a process that allows for the grinding of cylindrical parts without the need for centers or fixtures. This method results in significantly reduced setup times and increased productivity. The ODM Cincinnati design utilizes a unique twin-grip principle, which stabilizes the workpiece and minimizes vibration during the grinding process, leading to enhanced precision and surface finish.

One of the notable features of the ODM Cincinnati Twin Grip Centerless Grinder is its robust construction. The machine is made from high-quality materials that can withstand the rigors of daily operation, ensuring longevity and consistent performance. The frame is designed to absorb shocks and vibrations effectively, which further improves the grinding accuracy. Additionally, the machine is equipped with an advanced coolant system that maintains optimal operating temperatures, reducing wear on grinding wheels and increasing overall efficiency.

odm cincinnati twin grip centerless grinder

The versatility of the Twin Grip Centerless Grinder makes it suitable for a variety of applications. It can process a wide range of materials, including steel, aluminum, and stainless steel, making it ideal for industries such as aerospace, automotive, and medical devices. The machine can handle different sizes and shapes of workpieces, from small components to larger cylindrical parts, providing manufacturers with the flexibility they need in today’s fast-paced market.

Another significant advantage of the ODM Cincinnati Twin Grip Centerless Grinder is its user-friendly control system. The intuitive interface allows operators to easily program and adjust settings, significantly reducing the learning curve for new users. Advanced automation options are available, enabling seamless integration into fully automated production lines. This not only enhances productivity but also ensures consistent quality across all parts produced.

Moreover, maintenance is simplified with the design of the Twin Grip Centerless Grinder. Routine checks and part replacements can be performed with minimal disruption to the production process. This reliability helps manufacturers reduce downtime, ultimately leading to increased output and profitability.

In summary, the ODM Cincinnati Twin Grip Centerless Grinder represents a significant advancement in grinding technology. Its unique twin-grip design, coupled with robust construction, versatility, and user-friendly controls, makes it a valuable asset for manufacturers seeking quality and efficiency. As industries continue to evolve, the demand for precise and reliable machining will only increase, and machines like the Twin Grip Centerless Grinder will undoubtedly play a pivotal role in meeting these challenges. Investing in such advanced machinery is a step toward enhancing production capabilities and achieving operational excellence in today's competitive market.