Exploring OEM Centerless Belt Grinding and Polishing Machines

In the world of manufacturing and metalworking, precision and efficiency are paramount. Among the various processes employed to achieve high-quality finishes and tolerances, centerless belt grinding and polishing machines have emerged as indispensable tools. These machines not only enhance productivity but also ensure consistency in the final product. As industries continue to evolve, Original Equipment Manufacturers (OEMs) are increasingly focusing on creating advanced solutions tailored to meet specific client needs.

Understanding Centerless Belt Grinding

Centerless belt grinding is a machining process that removes material from a workpiece to achieve the desired shape and finish. Unlike traditional grinding methods that utilize a fixed spindle, centerless grinding employs an ingenious system where the workpiece is held between two wheels the grinding wheel and the regulating wheel. This setup allows for continuous operation, resulting in higher efficiency and reduced cycle times.

The belt aspect of the process involves using a belt coated with abrasive materials, which is wrapped around a wheel. This configuration provides a larger surface area for grinding, leading to improved grinding performance and better heat dissipation. As a result, manufacturers can produce parts with tighter tolerances and superior surface finishes, essential for industries such as aerospace, automotive, and medical devices.

Polishing for Perfection

While grinding prepares the workpiece by removing excess material, polishing is the final touch that enhances aesthetic appeal and corrosion resistance. Premium OEM centerless belt grinding and polishing machines are designed to seamlessly transition between grinding and polishing operations. This versatility encourages efficiency, as operators can produce finished components without needing to switch equipment.

Polishing is particularly critical for applications where appearance is key, such as decorative parts in consumer goods or components used in highly-visible applications. The right polishing solution can dramatically improve the product's marketability while ensuring compliance with industry standards.

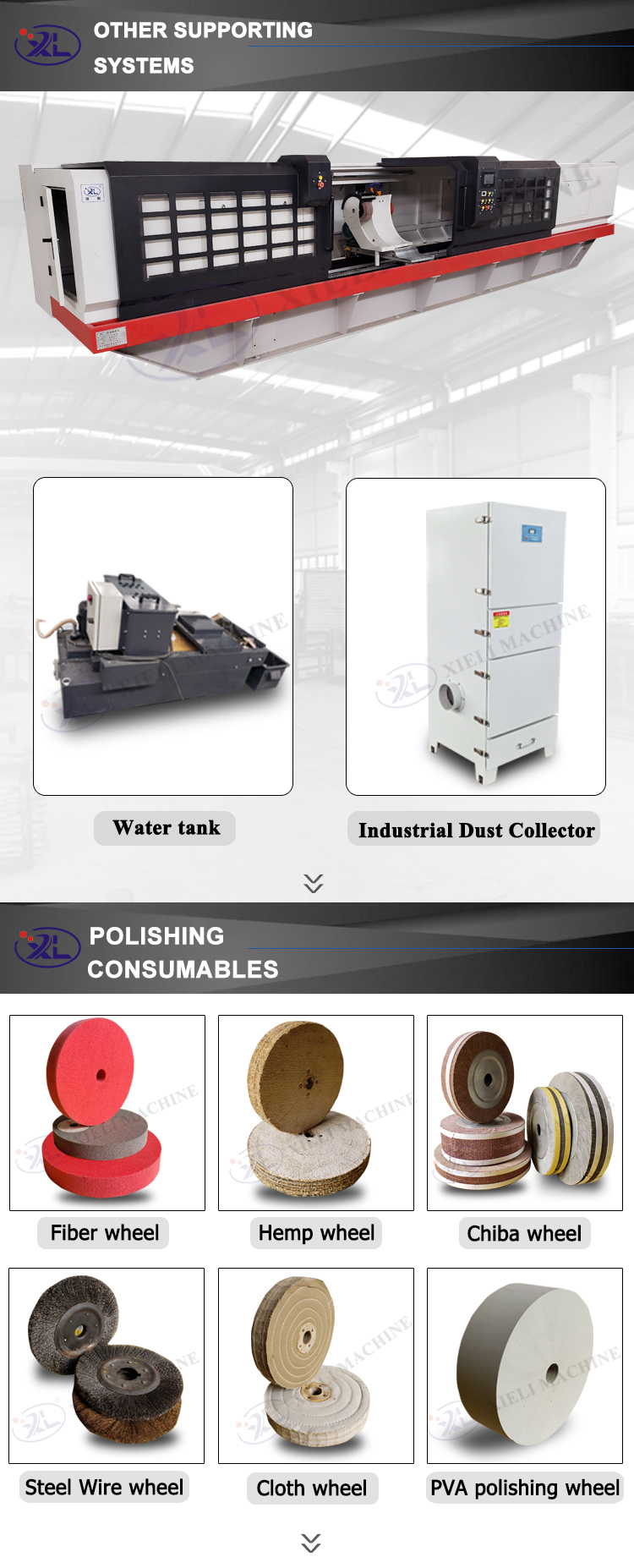

oem centerless belt grinding polishing machine

The Importance of OEM Solutions

Choosing an OEM centerless belt grinding and polishing machine provides several advantages. Firstly, OEMs offer customized solutions tailored to specific manufacturing requirements, allowing businesses to optimize their processes. This focus on customization can significantly enhance productivity, enabling manufacturers to scale operations to meet market demands.

Moreover, OEMs commit to providing ongoing support and maintenance, ensuring that machines operate at peak performance. This relationship fosters a dependable quality assurance process, which is crucial in sectors where safety and compliance are paramount.

Innovation and Technological Advancements

As technology advances, OEM centerless belt grinding and polishing machines are becoming increasingly sophisticated. Automation features, such as programmable logic controllers (PLCs) and integrated sensors, enhance precision and user-friendliness. These developments help in monitoring various parameters, optimizing speeds, and detecting potential issues early, which minimizes downtime.

Integration with Industry 4.0 concepts is also on the rise, with machines capable of sending and receiving data through the Internet of Things (IoT). This connectivity allows manufacturers to analyze performance metrics in real-time and make data-driven decisions for continuous improvement.

Conclusion

In summary, OEM centerless belt grinding and polishing machines are vital tools in the modern manufacturing landscape. By combining efficiency, precision, and the latest technological advancements, these machines enable businesses to produce high-quality parts that meet stringent industry standards. As manufacturers continue to prioritize quality and efficiency, investing in innovative OEM solutions will undoubtedly play a crucial role in their success and growth in an increasingly competitive market.