The Importance of Selecting the Right Through-Feed Centerless Grinder Supplier

In the high-precision manufacturing sector, the process of grinding plays a crucial role in ensuring the quality and accuracy of components. Among the numerous grinding methods, centerless grinding stands out due to its efficiency and ability to produce highly accurate parts at high volumes. Through-feed centerless grinders specifically are designed to allow continuous processing of long workpieces without the need for loading and unloading fixtures. As such, choosing the right supplier for through-feed centerless grinders is vital for manufacturers looking to streamline their production processes and improve overall efficiency.

Understanding Through-Feed Centerless Grinding

Through-feed centerless grinding is a technique where the workpiece passes through two grinding wheels, with one wheel performing the grinding and the other serving to support the workpiece. This method is particularly advantageous for producing cylindrical parts with precise dimensions, superior surface finishes, and a high degree of repeatability. It is commonly utilized in industries that require high-volume production, such as automotive, aerospace, and medical device manufacturing.

Selecting a Reliable Supplier

1. Experience and Reputation When searching for a through-feed centerless grinder supplier, one of the first factors to consider is their experience in the industry. A supplier with a proven track record and positive customer testimonials is more likely to provide reliable equipment and support services. Researching online reviews, client case studies, and industry accolades can provide insight into a supplier’s standing in the market.

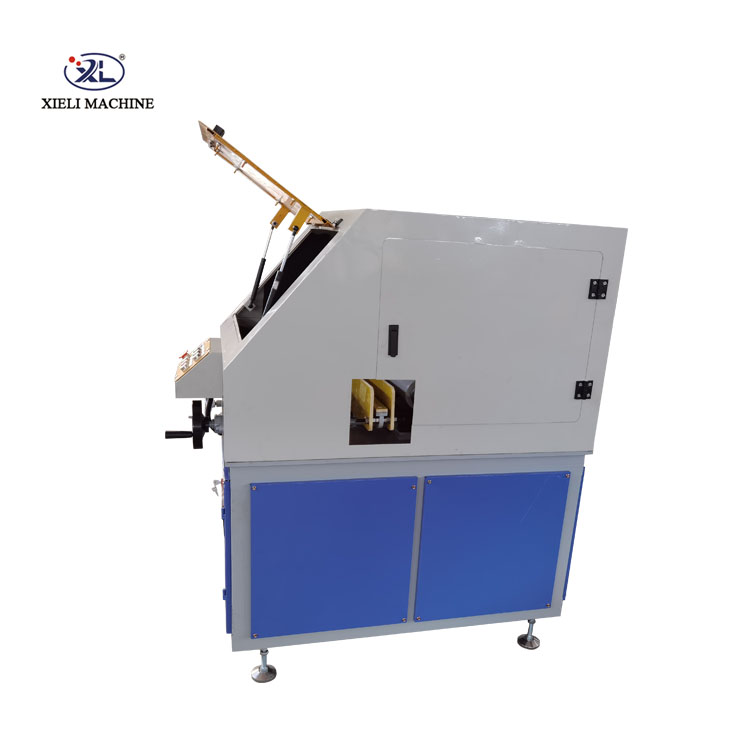

through feed centerless grinder supplier

2. Quality of Equipment The quality of the grinder itself is paramount. A well-manufactured machine will not only deliver consistent results but will also stand the test of time. Look for suppliers that use high-grade materials and advanced manufacturing techniques. Additionally, inquire about the machine's specifications, such as motor power, wheel speed, and automation features, to ensure it meets your specific production needs.

3. Customization Options Every manufacturing process is unique, and flexibility is key. A good supplier will offer customization options for their through-feed centerless grinders, allowing you to modify the equipment to better suit your specific applications. This could include adjustments in wheel size, machine configuration, or the integration of additional features such as automation and robotics.

4. After-Sales Support The journey does not stop upon the purchase of a grinder. Ongoing support, including installation, training, and maintenance, is essential for maximizing the performance of the equipment. A responsive supplier that offers comprehensive after-sales service can significantly reduce downtime and enhance productivity. Make sure to inquire about the availability of service personnel, spare parts, and operator training programs.

5. Cost vs. Value While it is important to consider the cost of the grinder, focusing solely on price can be misleading. It is essential to evaluate the overall value offered by the supplier. Factor in aspects such as machine lifespan, efficiency, energy consumption, and potential savings in labor costs. A more expensive machine may yield greater long-term savings and productivity enhancements.

Conclusion

In conclusion, selecting the right through-feed centerless grinder supplier is a critical decision that can significantly impact a manufacturer’s productivity and product quality. It is essential to evaluate several factors—including the supplier's experience, equipment quality, customization options, after-sales support, and overall value—before making a choice. Investing time in finding the right supplier will pay off in the form of improved manufacturing processes, enhanced efficiency, and ultimately, greater competitiveness in the market.