The Cincinnati Milacron 220-8 Centerless Grinder A Precision Tool for Global Industries

In today’s fast-paced manufacturing environment, precision and efficiency are paramount. One machine that exemplifies these qualities is the Cincinnati Milacron 220-8 Centerless Grinder. Renowned for its robust design and exceptional performance, this machine has become a cornerstone in various industries, ranging from automotive to aerospace. Its reputation as a reliable machining tool has spurred interest from international markets, making it a sought-after exporter for many manufacturing sectors.

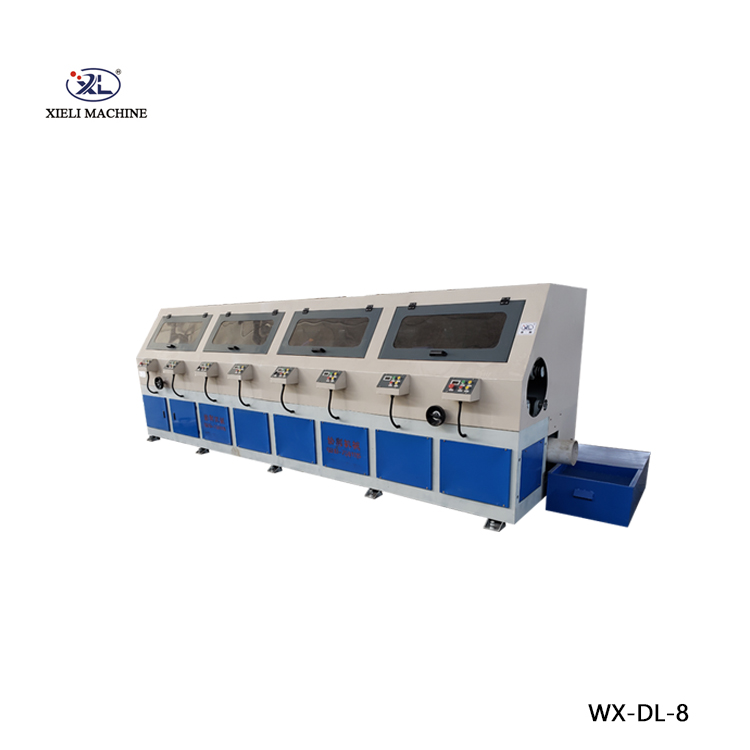

The Cincinnati Milacron 220-8 features an innovative centerless grinding design that allows for the efficient grinding of parts without the need for complex setups or fixtures. This is particularly beneficial for high-volume production runs, where speed and accuracy can significantly impact overall productivity and cost-effectiveness. The grinder employs a unique infeed and through-feed mechanism, which ensures that the workpieces are fed seamlessly into the grinding area. This process not only minimizes downtime but also enhances the quality of the finished products, making the 220-8 a preferred choice for manufacturers aiming for the best possible outcomes.

One of the standout features of the 220-8 machine is its versatility. It can accommodate a wide range of materials and part sizes, making it suitable for diverse applications. Whether dealing with small precision parts or larger components, this grinder can be easily adjusted to meet specific production needs. Furthermore, the machine's capability to handle various geometries allows manufacturers to produce complex shapes with high precision, further solidifying its place in industries that require exacting standards.

cincinnati milacron 220-8 centerless grinder exporter

Another remarkable aspect of the Cincinnati Milacron 220-8 is its durability. Built from high-quality materials, this centerless grinder is designed to withstand the rigors of continuous operation, ensuring minimal wear and tear over time. This durability translates into lower maintenance costs and reduced downtime, which is crucial for manufacturers who need to keep their operations running smoothly. As a result, many companies view the investment in a Cincinnati Milacron 220-8 as a long-term strategy, ensuring consistently high productivity and quality.

The global demand for precision grinding machines continues to rise, and the Cincinnati Milacron 220-8 is well-positioned to meet this need. Exporters of this machine have tapped into various international markets, recognizing the increasing reliance on advanced manufacturing techniques across the globe. Countries that emphasize high-quality manufacturing processes, such as Germany, Japan, and the United States, are significant markets for the 220-8 centerless grinder. Additionally, emerging economies in Asia and South America offer new opportunities for exports as these regions develop their manufacturing capabilities.

The importance of reliable support and service cannot be underestimated when it comes to exports. Manufacturers and exporters of the Cincinnati Milacron 220-8 often provide extensive training and technical support, ensuring that clients can maximize the machine’s capabilities. This commitment to customer service enhances the machine's appeal and encourages repeat business, further expanding the Cincinnati Milacron brand's global footprint.

In conclusion, the Cincinnati Milacron 220-8 Centerless Grinder stands out as a premier choice for industries that demand precision, versatility, and durability. Its advanced features and reliable performance make it an essential tool for manufacturers worldwide. As the demand for high-quality precision grinding solutions continues to grow, the export potential for the Cincinnati Milacron 220-8 remains promising, paving the way for future advancements in manufacturing technology. With a strong commitment to excellence in both product and service, the Cincinnati Milacron brand is well on its way to becoming a leader in the global machining landscape.