The Pipe End Grinding Machine Factory Revolutionizing Pipe Finishing Processes

In the manufacturing world, the finishing process of pipes plays a crucial role in ensuring product quality, performance, and aesthetics. Among various finishing processes, grinding is considered one of the most effective methods to prepare the ends of pipes for further applications. The pipe end grinding machine factory stands at the forefront of this essential manufacturing process, providing innovative solutions that enhance efficiency, precision, and quality.

Understanding Pipe End Grinding Machines

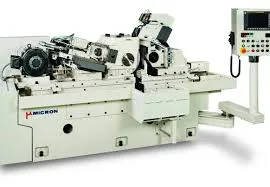

A pipe end grinding machine is designed specifically to achieve precise finishes on the edges of pipes. This machine operates by removing material from the ends of the pipe, creating a smooth, uniform surface that allows for better fitting, welding, or other operations that the pipes may undergo. The grinding process also eliminates any burrs or irregularities, which can compromise the integrity of the pipeline system.

The importance of properly finished pipe ends cannot be overstated. In industries such as oil and gas, construction, and manufacturing, ensuring tight seals and connections is critical. Poorly finished pipe ends can lead to leaks, structural failures, and even safety hazards, making the role of a pipe end grinding machine pivotal.

The Factory A Hub of Innovation and Technology

The pipe end grinding machine factory is not just a production site; it is a hub of innovation and technology. Here, skilled engineers and technicians work diligently to develop machines that integrate advanced technologies, such as computer numerical control (CNC), automation, and sophisticated grinding technology. These advancements allow for highly accurate grinding processes, significantly reducing the time required to finish pipes while maintaining high-quality standards.

A sophisticated pipe end grinding machine typically features adjustable grinding speeds, different grinding wheel options, and programmable controls that give operators the flexibility to handle various pipe diameters and materials. This versatility is essential in today’s manufacturing landscape, where customization and adaptability are crucial.

The Benefits of High-Quality Pipe End Grinding Machines

pipe end grinding machine factory

Investing in high-quality pipe end grinding machines yields significant benefits for manufacturers. Firstly, the precision offered by these machines leads to a decrease in material waste. By ensuring that pipes are ground correctly the first time, manufacturers can avoid costly reworks and reduce the overall consumption of materials.

Secondly, the efficiency provided by modern grinding machines helps manufacturers meet tight production schedules. With automation features and quicker setup times, these machines can operate continuously, maximizing output and minimizing downtime. This efficiency is a key factor in staying competitive in the global market.

Moreover, the enhanced safety features found in modern machines contribute to a safer working environment. Advanced design elements minimize the risk of accidents and injuries, allowing operators to work confidently while maintaining productivity.

Sustainable Practices in Pipe End Grinding Machine Manufacturing

As industries worldwide increasingly prioritize sustainability, the pipe end grinding machine factory is also adapting to eco-friendly practices. This includes the use of energy-efficient machinery, sustainable materials in manufacturing, and processes designed to minimize waste and emissions. A commitment to sustainability not only helps the environment but also appeals to a growing segment of environmentally conscious customers.

Conclusion

The pipe end grinding machine factory is essential in the manufacturing supply chain, providing critical technology that enhances the quality and performance of pipes. Through innovative engineering, advanced technology, and a commitment to sustainability, these factories are not just producing machines; they are shaping the future of pipe processing. As industries continue to evolve and demand higher standards, the importance of high-quality pipe end grinding machines will only grow, underscoring the factory's role as a cornerstone of modern manufacturing.

In a world where precision, safety, and sustainability are paramount, investing in the capabilities offered by pipe end grinding machinery is an important step for manufacturers aiming to thrive in a competitive landscape. The future of pipe finishing is here, and it promises to bring efficiency and quality to new heights.