Infeed Centerless Grinder Suppliers Revolutionizing Precision Machining

In the world of precision machining, the quest for higher efficiency and accuracy is ever-present. One of the key technologies facilitating this advancement is the centerless grinder, specifically the infeed centerless grinder. This machine has been instrumental in achieving consistent results in the production of round bars, tubes, and various cylindrical parts. The demand for infeed centerless grinders has surged, leading to a growing market for specialized suppliers.

Understanding Infeed Centerless Grinding

Infeed centerless grinding is a process that allows manufacturers to grind cylindrical parts without the need for a separate chucking mechanism. This method is particularly useful for producing complex shapes and precision components. The key advantage of infeed grinding is the ability to grind parts with a varying diameter in a single pass, which significantly reduces production time and helps maintain tight tolerances.

During the infeed grinding process, the workpiece is fed into the machine between two grinding wheels. The first wheel, known as the grinding wheel, performs the actual grinding, while the second wheel, called the regulating wheel, controls the rotational speed and provides the axial feed motion. This configuration allows for precise control of the grinding process, making it ideal for high-volume production environments.

The Role of Suppliers

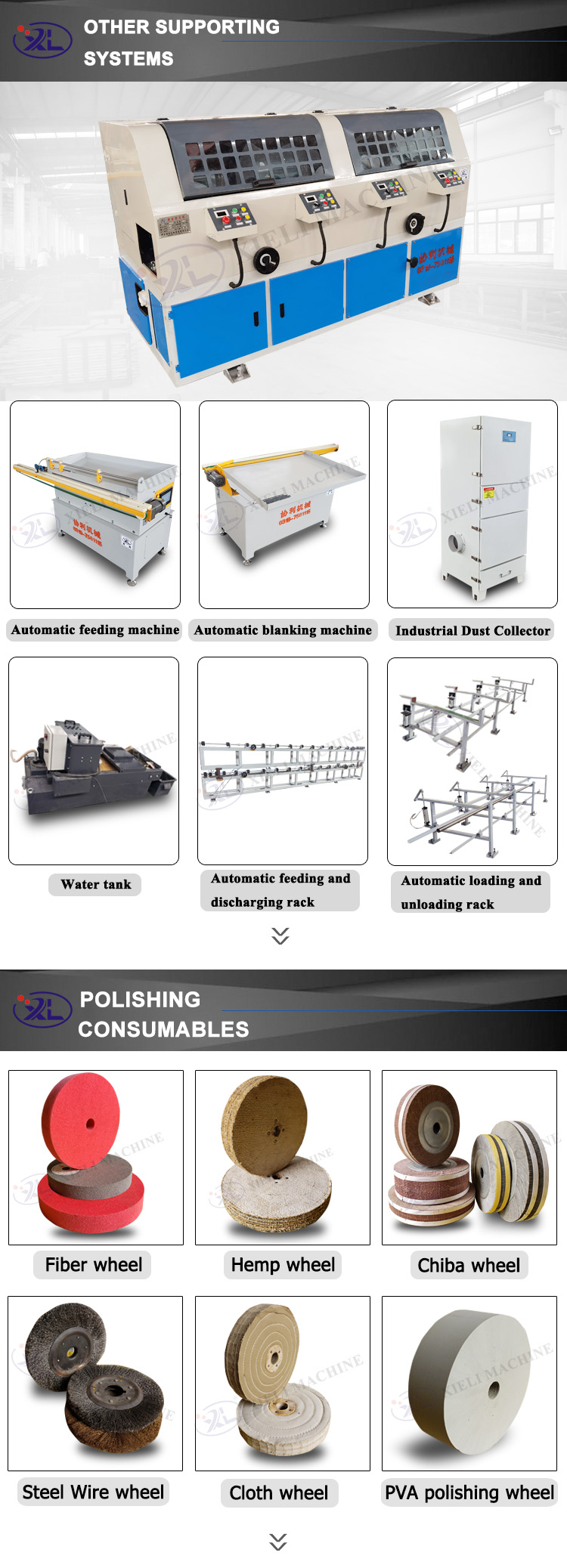

The role of infeed centerless grinder suppliers is crucial in ensuring that manufacturers have access to the latest technology and support necessary for optimal operations. Quality suppliers offer a range of machine configurations tailored to specific machining needs. They provide not only the machinery but also the essential components, tooling, and accessories that enhance the performance of centerless grinders.

Suppliers also offer vital services including installation, training, and ongoing maintenance support. This service-oriented approach helps manufacturers minimize downtime and increase productivity. By partnering with reliable suppliers, companies can benefit from efficient machining processes and extend the life of their equipment.

Choosing the Right Supplier

infeed centerless grinder supplier

When selecting an infeed centerless grinder supplier, manufacturers should consider several factors. Firstly, the supplier’s reputation in the industry is paramount. Established suppliers with a history of delivering high-quality machines tend to foster trust and reliability among their customers.

Another important consideration is the range of products offered. A diverse portfolio allows manufacturers to find machines that fit their specific requirements, whether for high-volume production runs or specialized applications. Additionally, suppliers that provide customization options can help businesses achieve unique machining goals.

After-sales support is another critical aspect. Robust customer service, including timely maintenance and troubleshooting, ensures that machines run smoothly without unexpected interruptions. Suppliers offering comprehensive training programs can also improve operators' skills, leading to better machining outcomes.

Future Trends in Centerless Grinding

The future of infeed centerless grinding is bright, with innovations continuing to emerge. Suppliers are increasingly incorporating advanced technologies like automation and digital monitoring into their machines. These advancements are aimed at enhancing operational efficiency and precision, allowing for real-time adjustments and data collection.

Moreover, the growing trend towards sustainability in manufacturing is influencing suppliers to develop energy-efficient machines that minimize waste and optimize resource use. The integration of smart technologies is expected to play a significant role in revolutionizing traditional grinding processes, making them more efficient and environmentally friendly.

Conclusion

In summary, suppliers of infeed centerless grinders are vital players in the precision machining industry. They provide the machinery, support, and innovations necessary to meet the demands of modern manufacturing. As technology continues to evolve, the collaboration between manufacturers and suppliers will lead to even greater advances in efficiency, precision, and sustainability within the machining sector. By investing in high-quality equipment and nurturing strong supplier relationships, manufacturers can stay ahead in a competitive landscape and achieve their production goals with greater ease.