Grinding and Polishing Equipment An Overview of Technologies and Applications

Grinding and polishing are essential processes in various industries, including manufacturing, metalworking, and woodworking. They are used to achieve fine surface finishes, enhance material properties, and prepare components for further fabrication. The equipment designed for grinding and polishing has evolved significantly, incorporating advanced technologies to improve efficiency and precision.

Types of Grinding Equipment

Grinding equipment is divided into several categories based on the method of material removal and the specific applications they serve. The most common types include

1. Belt Grinders These machines utilize an abrasive belt to grind surfaces and edges. They are versatile and widely used for shaping, polishing, and finishing a variety of materials, from metals to plastics. Belt grinders are especially valuable in metalworking shops, where they help to prepare parts for welding and assembly.

2. Surface Grinders Surface grinding machines use a rotating disk with grinding wheels to create a flat surface on a workpiece. This type of equipment is crucial for achieving precise dimensions and smooth finishes, making it an integral part of tool-making and machining operations.

3. Cylindrical Grinders Designed for grinding the external or internal surfaces of cylindrical parts, these machines are essential in the production of shafts, spindles, and other round components. Cylindrical grinders can be horizontal or vertical and are valued for their accuracy and repeatability.

4. Tool and Cutter Grinders These specialized machines are used to sharpen and maintain cutting tools. They can grind various types of tools, including drills, end mills, and reamers, ensuring that they remain effective and capable of producing high-quality work.

Polishing Equipment

Polishing equipment is tailored to achieve a high-gloss finish on surfaces

. This equipment includes1. Polishing Machines These are typically equipped with rotating pads or belts coated with fine abrasives. They are widely used in metal finishing, automotive detailing, and jewelry manufacturing. Polishing machines can be bench-mounted or floor-standing, depending on the scale of operations.

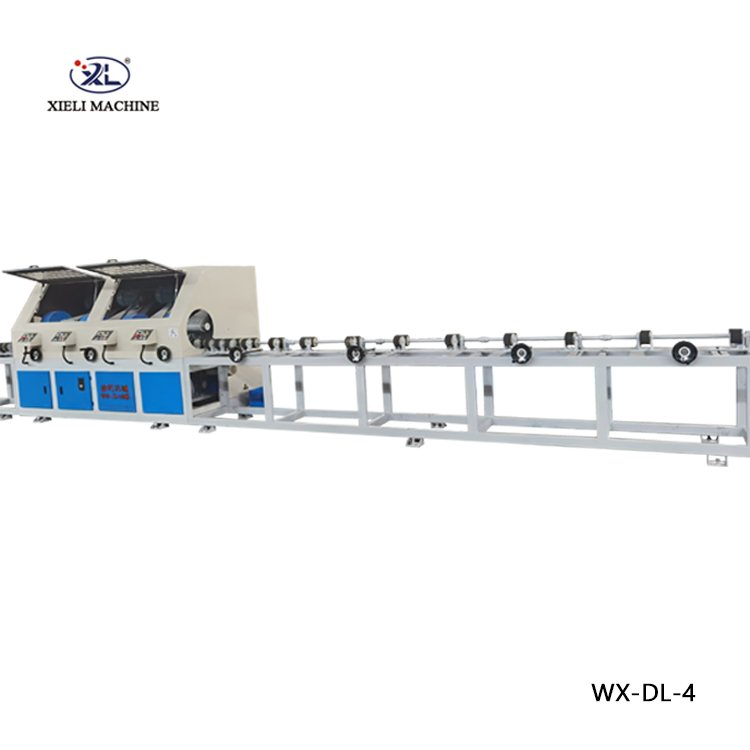

grinding and polishing equipment

2. Lapidary Equipment Used primarily for polishing gemstones, lapidary machines feature a series of grinding wheels and polishing pads that progressively refine the surface of stones. These machines ensure that gemstones exhibit brilliance and are free of scratches.

3. Manual Polishing Tools Handheld tools, including polishers and buffing wheels, are often used for detailed work, especially in smaller shops or for intricate projects. These tools allow for greater control over the polishing process but may require more effort and skill.

Emerging Technologies

Recent advancements in grinding and polishing equipment have introduced innovations such as computer numerical control (CNC) systems, which enhance precision and automation. CNC grinding machines can produce complex shapes and features with minimal human intervention, significantly improving productivity.

Moreover, the integration of automation and robotics has revolutionized the industry, enabling manufacturers to streamline operations and reduce cycle times. Robotic arms equipped with grinding and polishing attachments can execute repetitive tasks with remarkable accuracy, leading to improved consistency and quality in finished products.

Applications Across Industries

Grinding and polishing equipment finds applications across a wide range of industries. In aerospace, precision grinding is essential for components like turbine blades, where surface finish and dimensional accuracy are critical. Similarly, in the automotive sector, grinding and polishing are crucial for engine parts and body panels to ensure performance and aesthetics.

In the world of electronics, grinding technology is used to achieve flat surfaces for circuit boards, while polishing plays a role in enhancing the conductivity of contact points. The medical field also relies on these processes for manufacturing surgical instruments and implants, where hygiene and precision are paramount.

Conclusion

Grinding and polishing equipment is vital in achieving the desired surface finishes and dimensional accuracy across various industries. As technology continues to evolve, the capabilities and efficiency of these machines will only improve, further emphasizing their significance in modern manufacturing processes. Understanding the types, applications, and advancements in grinding and polishing equipment can empower businesses to leverage these tools for increased quality and productivity.