Exploring the Cincinnati 2 Centerless Grinder A Precision Tool for Modern Manufacturing

In today's fast-paced manufacturing environment, the quest for precision, efficiency, and reliability has never been more critical. Among the array of equipment that contributes to these goals, the Cincinnati 2 Centerless Grinder stands out as an exemplary tool designed for high-performance applications in various industries.

Introduction to Centerless Grinding

Centerless grinding is a method of removing material from a workpiece without the need for a spindle or fixture to hold it in place. Instead, the workpiece is supported by two wheels, and it is precisely located between them, allowing for continuous grinding operations. This method offers significant advantages, including the ability to grind long, thin parts with minimal distortion, making it ideal for applications in automotive, aerospace, and medical sectors.

The Cincinnati 2 Centerless Grinder Key Features

The Cincinnati 2 Centerless Grinder is renowned for its robust construction and innovative design. Manufactured by Cincinnati Milacron, a company with a rich history in the grinding machine industry, the Cincinnati 2 is tailored to meet the demanding requirements of modern manufacturing.

1. Precision and Accuracy The Cincinnati 2 is engineered to provide exceptional precision in grinding operations. It features advanced spindle design and high-precision grinding wheels that work together to achieve tolerances within micro-inches. This level of accuracy is essential for parts that require tight specifications.

2. Versatility One of the standout features of the Cincinnati 2 is its versatility. It can accommodate a wide range of materials and part sizes, making it suitable for various applications—from simple cylindrical shapes to complex geometries. This adaptability makes it a valuable addition to any machining workshop.

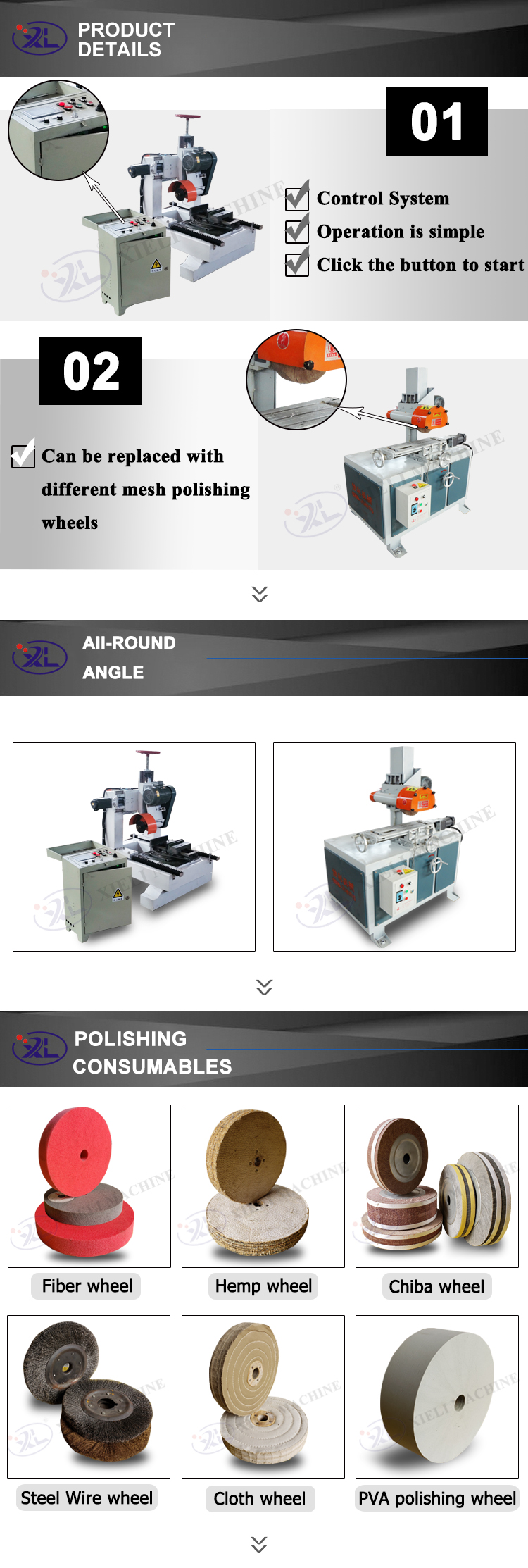

3. User-Friendly Interface The Cincinnati 2 incorporates an intuitive control system, allowing operators to adjust settings effortlessly. This user-friendly interface minimizes the learning curve for new users and improves overall efficiency, reducing downtime during setups.

cincinnati 2 centerless grinder product

4. Robust Build Quality Constructed from high-quality materials, the Cincinnati 2 is built to withstand the rigors of continuous operation. Its durable components ensure longevity and reliability, reducing the need for frequent maintenance and repairs.

5. Enhanced Automation In an age where automation is increasingly becoming the norm, the Cincinnati 2 integrates seamlessly with automated systems. It can be equipped with feeding mechanisms and robotics to further streamline production processes, enhancing overall throughput and reducing labor costs.

Applications and Industries

The Cincinnati 2 Centerless Grinder is utilized in numerous industries due to its exceptional performance and reliability. Common applications include the grinding of shafts, pins, bushings, and various cylindrical components. The automotive industry often relies on this grinder for producing precision parts like valve lifters, rocker arms, and fuel injectors.

In the aerospace sector, where tolerances are critical, the Cincinnati 2 delivers the precision needed for components used in aircraft engines and landing gear systems. Additionally, in the medical field, it is utilized to produce high-precision parts for surgical instruments and implants, ensuring patient safety and product reliability.

Conclusion

The Cincinnati 2 Centerless Grinder epitomizes the advancements in grinding technology, providing manufacturers with a powerful tool that enhances precision and efficiency. With its robust design, user-friendly interface, and versatility, it is an essential piece of equipment for those looking to stay competitive in today’s manufacturing landscape.

By investing in a Cincinnati 2 Centerless Grinder, organizations can not only improve their production capabilities but also ensure that they meet the stringent quality standards required across various industries. As the demand for precision engineering continues to grow, the Cincinnati 2 stands ready to meet the challenges of modern manufacturing head-on. Embracing such advanced machinery is key to thriving in a continually evolving marketplace.