Surface polishing machines have revolutionized modern industries with their exceptional ability to enhance surface finishes. Designed for precision, these machines cater to a variety of applications, ranging from automotive to electronics. Their importance can be understood by evaluating their performance, versatility, and technological advancements.

Surface polishing machines are engineered for precision, providing unparalleled finishes. Industries like automotive, aerospace, and manufacturing heavily rely on these machines to ensure that metal and composite surfaces achieve their required smoothness and consistency. Expertise in handling different materials—from aluminum to complex alloys—is essential. For instance, the polishing machine must adapt to each material's unique properties to prevent overheating or damage during the polishing process. Mastering such technical nuances emphasizes the machine's value in maintaining quality standards across industries.

Integration of cutting-edge technology in surface polishing machines underscores their authority and reliability. Modern machines incorporate digital controls, automated processes, and real-time monitoring, which enhance performance while reducing human error. As a testament to their technological prowess, these machines often feature programmable settings, enabling users to customize operations to meet specific requirements. Advanced models even use AI-driven algorithms to optimize the polishing process, maximizing output efficiency. This authoritative control over the polishing parameters not only boosts productivity but also guarantees consistency.

Trustworthiness is key when considering surface polishing machines, especially given the critical nature of their application. Industry professionals are keen on machines that promise durability and consistent performance. Brands that invest in research and development often lead the market, ensuring their products not only adhere to industry standards but occasionally set new benchmarks. Client testimonials and long-term partnership case studies with reputable companies enhance the perceived reliability of these machines.

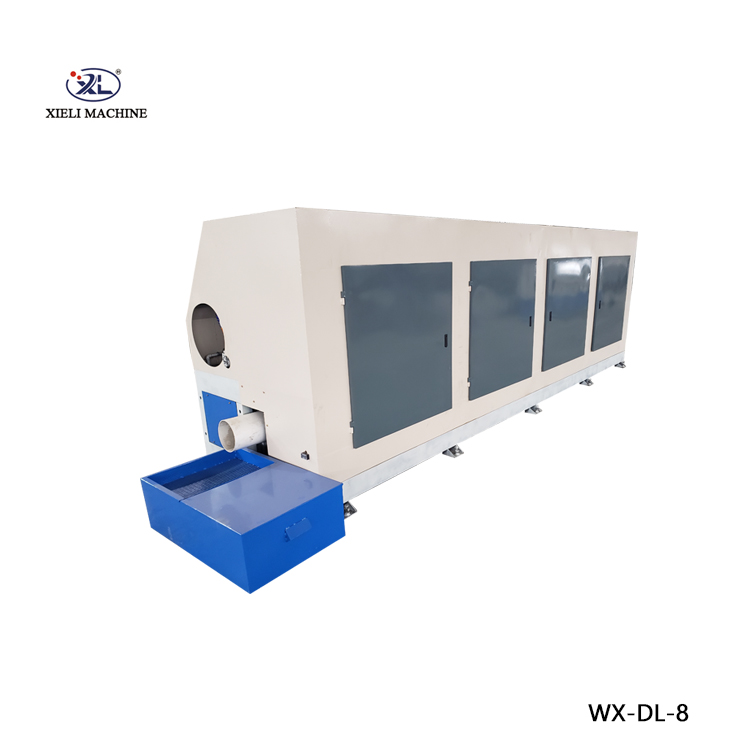

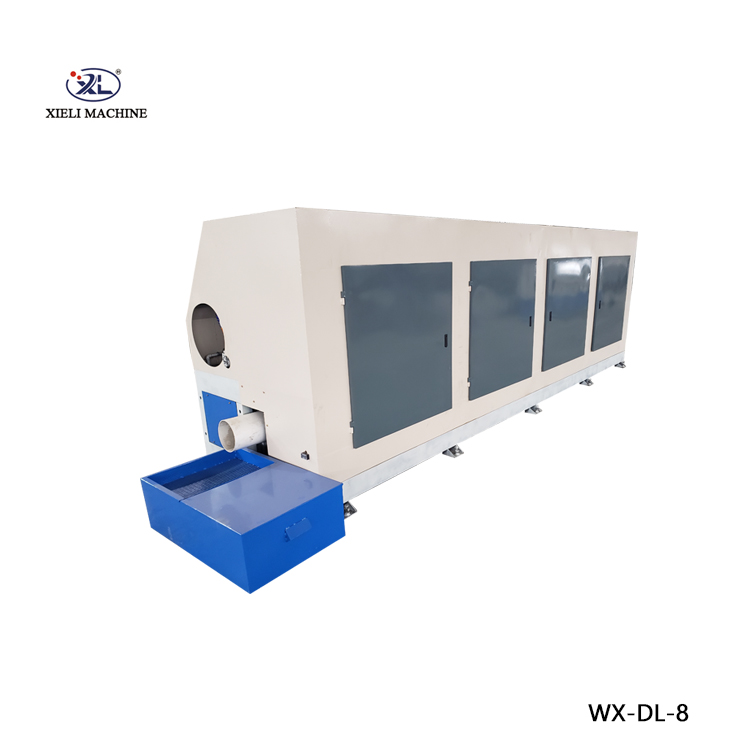

surface polishing machine

In real-world scenarios, the experience of using surface polishing machines frequently highlights their user-friendliness and adaptability. Operators often commend the machines' intuitive interfaces and the ease with which novice users can conduct high-quality polishing tasks. Additionally, maintenance is streamlined, with many machines designed for easy disassembly, ensuring quick and effective troubleshooting. Features like dust extraction systems and noise reduction not only improve the working environment but underscore their dedication to operator health and safety.

Looking at the long-term benefits, these machines contribute significantly to operational efficiency and cost-effectiveness. By achieving the desired finish in fewer passes and less time, manufacturers can increase throughput, reducing overall production costs. In sectors where surface quality directly impacts the end-product performance, such as semiconductor manufacturing, the investment in high-quality surface polishing machines pays dividends.

To sum up, surface polishing machines play a pivotal role in the industrial landscape. Their advanced engineering, coupled with user-centric design and cutting-edge technology, positions them as indispensable tools in a variety of sectors. The blend of precise craftsmanship and authoritative performance ensures they meet the highest production standards, making them a wise investment for enterprises aiming for excellence.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.