The Importance of Stainless Steel Tube Polishing Machines

In the world of manufacturing and material processing, the quality and appearance of final products are crucial. Stainless steel, known for its durability, corrosion resistance, and aesthetic appeal, is a widely used material in various industries, including construction, automotive, and food processing. One of the pivotal processes in enhancing the quality of stainless steel products is tube polishing, which ensures not only a visually appealing finish but also prolongs the material's lifespan.

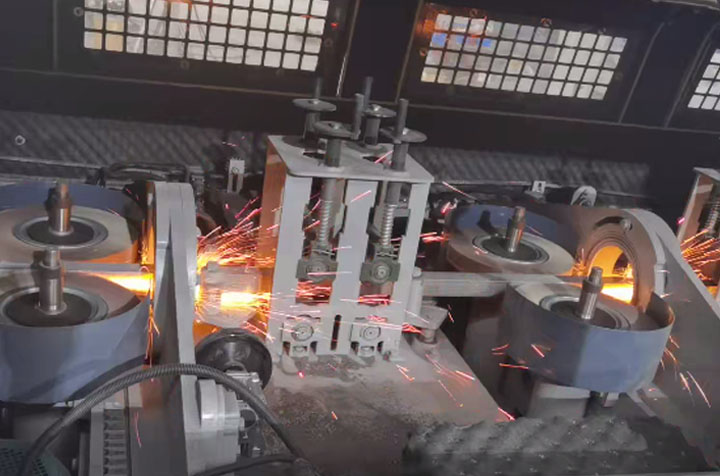

Stainless steel tube polishing machines are specialized equipment designed to give stainless steel tubes a high-gloss finish while also removing surface imperfections. The process typically involves the use of abrasives, compounds, and specialized polishing pads, allowing manufacturers to achieve a mirror-like sheen on their products. This polished finish is not only advantageous for aesthetics but also for functional purposes; polished surfaces are easier to clean, reducing the risk of contamination in hygienic environments.

When considering investments in stainless steel tube polishing machines, companies are often focused on quotes or estimates. The cost of these machines can vary significantly based on their size, capabilities, and the technology employed. Automated polishing machines tend to be on the higher end of the price spectrum, offering enhanced efficiency and consistent results, whereas manual machines may present a lower initial investment but can lead to higher labor costs and variability in quality.

stainless steel tube polishing machine quotes

It is essential for businesses to evaluate their production needs when seeking quotes for polishing machines. Factors such as the volume of tubes to be processed, the required surface finish, and the overall budget play a vital role in decision-making. Many manufacturers offer customization options, allowing companies to tailor machines to their specific requirements, further influencing the pricing.

Additionally, potential buyers should consider the after-sales support and warranty when obtaining quotes. A reliable supplier will not only provide a quality machine but will also offer maintenance services, spare parts, and training for operators. This support can significantly impact the long-term operation and efficiency of the polishing process.

In conclusion, investing in a stainless steel tube polishing machine is a significant decision for any manufacturer focused on enhancing product quality. By carefully comparing quotes and considering individual production needs, businesses can select the most suitable equipment that meets their demands while ensuring a polished finish that boosts both durability and aesthetics of their stainless steel tubes.