The Evolution of Centerless Grinding Machines A New Era in Precision Manufacturing

In the realm of precision manufacturing, centerless grinding has emerged as a cornerstone process, providing unparalleled accuracy and efficiency in shaping cylindrical parts. With the advent of new centerless grinding machine factories, the industry is undergoing a significant transformation, driven by technological advancements, improved production techniques, and ever-increasing demands for precision in manufacturing.

Understanding Centerless Grinding

Centerless grinding is a machining process that employs the use of three main components the grinding wheel, the regulating wheel, and the workpiece itself, which is held between these wheels. Unlike traditional grinding methods where the workpiece is held in place, centerless grinding allows for continuous and automated processing, making it an ideal solution for mass production. This method is particularly effective for producing components such as shafts, rods, and tubes that require high dimensional accuracy.

Technological Advancements

The most notable improvements in modern centerless grinding machines stem from advancements in technology. New factories are investing in state-of-the-art equipment that incorporates digital controls, advanced sensors, and automation capabilities. These innovations enhance the overall efficiency of the grinding process, allowing for real-time monitoring and adjustments to maintain consistent quality.

Moreover, the integration of artificial intelligence (AI) and machine learning algorithms enables predictive maintenance, which minimizes downtime and maximizes productivity. By analyzing data collected during the grinding process, these intelligent systems can forecast potential issues and schedule maintenance before they lead to equipment failure.

Enhanced Precision and Quality Control

One of the key benefits of the latest centerless grinding machines is their ability to achieve tighter tolerances and superior surface finishes. In sectors such as aerospace, automotive, and medical device manufacturing, the need for precision is critical. New grinding machines are equipped with advanced measuring systems that provide immediate feedback on the dimensions and quality of the workpieces, ensuring that they meet stringent industry standards.

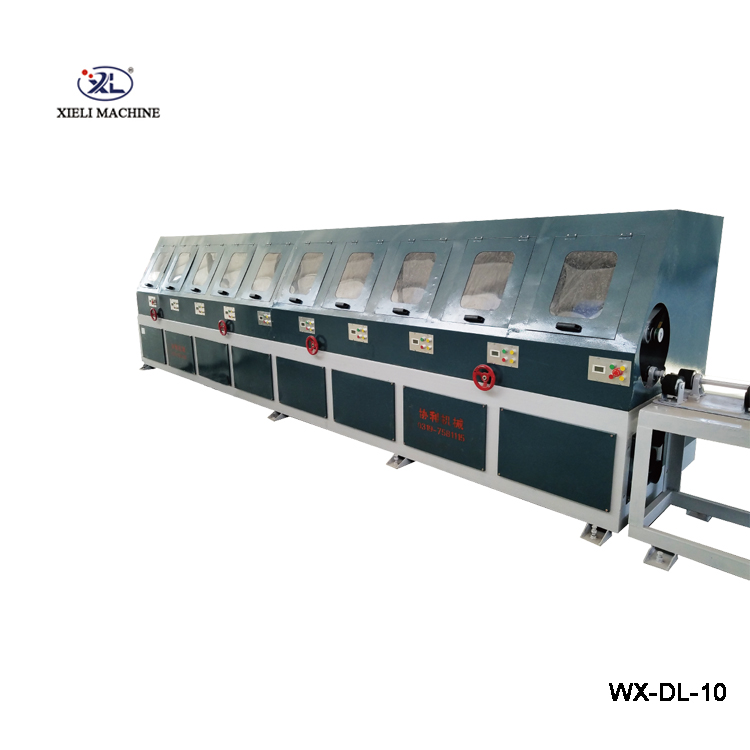

new centerless grinding machine factories

These quality control measures also extend to the entire manufacturing process. By employing in-process gauging, manufacturers can catch discrepancies early, reducing waste and rework. This level of quality assurance not only saves time but also enhances customer satisfaction by delivering superior products.

Sustainability and Eco-Friendliness

As industries shift towards more sustainable practices, new centerless grinding machine factories are also focusing on eco-friendliness. Modern machines are designed to consume less energy and generate less waste compared to their predecessors. By optimizing the grinding process and reducing cycle times, manufacturers are able to minimize their environmental footprint.

Additionally, many factories are adopting recycling methods for grinding fluids and abrasives, contributing to a more sustainable manufacturing process. Such initiatives not only comply with environmental regulations but also align with the global call for greener manufacturing solutions.

Conclusion The Future of Centerless Grinding

The emergence of new centerless grinding machine factories marks a significant milestone in the evolution of precision manufacturing. As these facilities continue to adopt innovative technologies and practices, they pave the way for a future where precision, efficiency, and sustainability coexist harmoniously.

With industries increasingly requiring high-quality components in shorter production times, the role of centerless grinding will only become more prominent. The next generation of grinding machines promises to push the boundaries of what's possible, offering manufacturers the tools they need to thrive in an increasingly competitive landscape.

In summary, the future of centerless grinding is bright, driven by technological advancements that enhance precision, improve efficiency, and foster sustainability. As new factories rise to meet these demands, the manufacturing sector is poised for a transformation that will redefine industry standards and expectations.