Throughfeed Centerless Grinder An Overview

Throughfeed centerless grinding is a specialized process used in manufacturing to efficiently grind cylindrical parts. This method is distinct from traditional center grinding as it allows for high-speed production of long, cylindrical workpieces without the need for fixed centers. As the name suggests, the workpieces are fed through the grinding machine, resulting in continuous operation that delivers high precision and productivity.

How Throughfeed Centerless Grinding Works

In a typical throughfeed centerless grinding setup, the workpiece is placed between two wheels the grinding wheel and the regulating wheel. The grinding wheel is responsible for removing material, producing the desired diameter and finish, while the regulating wheel controls the speed of the workpiece as it moves through the machine. The angle at which these wheels are positioned is crucial, as it allows for the effective grinding of the workpiece's outer diameter.

As the workpiece is fed into the machine, it is supported by a blade or a rest that maintains its position. This setup enables the workpiece to be ground continuously without needing to be repositioned, allowing for a streamlined manufacturing process. The result is not only improved efficiency but also greater consistency in the quality of the finished products.

Applications

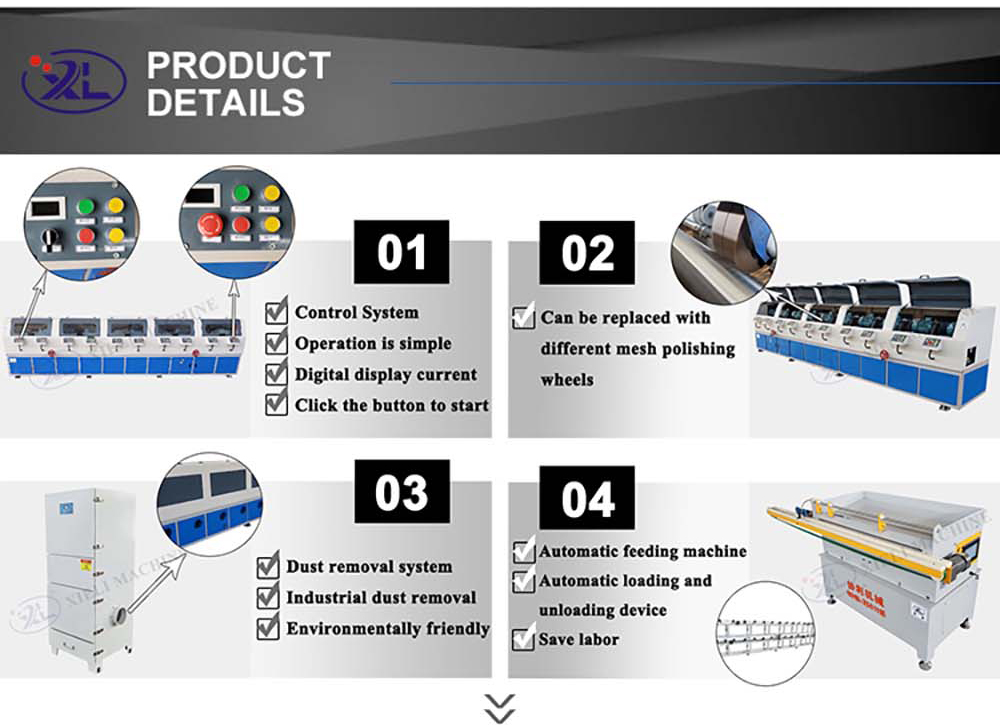

throughfeed centerless grinder

Throughfeed centerless grinders are widely utilized in various industries where precision and speed are paramount. Typical applications include the grinding of components such as shafts, rods, and tubes, which are commonly found in automotive, aerospace, and medical device manufacturing. The ability to produce parts with tight tolerances and smooth finishes makes this method highly desirable.

Advantages of Throughfeed Centerless Grinding

One of the main advantages of throughfeed centerless grinding is its ability to handle high volumes of production. Because the process is continuous, manufacturers can achieve significant output rates, reducing the overall manufacturing cycle times. Additionally, the design of the machine allows for minimal setup time, which is crucial in today’s fast-paced manufacturing environments.

Another key benefit is the consistency it provides. By eliminating the need for workpiece setups and handling equipment, the process significantly reduces the risk of human error and variations in part quality. Furthermore, the precision of the grind allows for less machining post-process, saving time and resources.

Conclusion

Throughfeed centerless grinding is a powerful technique in modern manufacturing, combining efficiency, high precision, and versatility. Its ability to produce high-quality cylindrical components at a rapid pace makes it a favorite in industries that demand stringent tolerances and excellent surface finishes. As technology continues to advance, we can expect to see further innovations in centerless grinding methods, further enhancing their effectiveness and application across diverse fields. Whether you're looking to increase production rates or ensure high-quality output, incorporating throughfeed centerless grinding into your processes could be a game-changer.