Centerless Grinder Regulating Wheels Manufacturers An Overview

Centerless grinding is a highly efficient manufacturing process used to shape and finish cylindrical components. A key element of this process is the regulating wheel, which plays a crucial role in controlling the workpiece's rotation and feed rate. As such, the manufacturers of centerless grinder regulating wheels are integral to the success of the grinding operation.

These manufacturers specialize in creating high-quality regulating wheels tailored to the specific needs of various grinding applications. The material, hardness, and surface finish of these wheels directly affect the performance of the centerless grinder. Common materials used include rubber, polyurethanes, and composite materials, each offering unique advantages. For instance, rubber wheels provide excellent traction and flexibility, while polyurethane wheels offer enhanced durability and minimal wear.

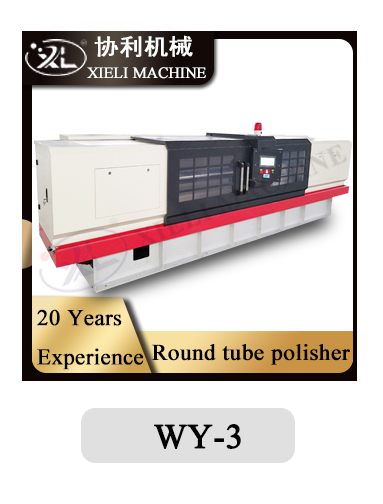

Leading manufacturers invest in advanced technology to produce regulating wheels that meet stringent industry standards. This often includes precision molding techniques, state-of-the-art grinding machinery, and rigorous quality control measures. By adopting these practices, manufacturers ensure that their products deliver consistent performance, reduced vibration, and extended operational life.

centerless grinder regulating wheels manufacturers

Customization is another crucial aspect of the regulating wheel manufacturing process. Each application may require specific dimensions, hardness levels, and abrasive materials for optimal performance. Reputable manufacturers work closely with customers to understand their unique grinding requirements, enabling them to create bespoke solutions that enhance productivity and efficiency. This tailored approach not only improves the grinding process but also helps in minimizing downtime and reducing operational costs.

Furthermore, environmental considerations are becoming increasingly important in the manufacturing sector. Many modern manufacturers are adopting eco-friendly practices, using sustainable materials, and implementing waste reduction strategies. By prioritizing sustainability, they not only comply with regulations but also appeal to a growing market segment that values environmentally responsible products.

The competitive landscape for centerless grinder regulating wheels is robust, with several key players dominating the market. These manufacturers differentiate themselves through innovation, superior customer service, and extensive product offerings. Businesses looking to procure regulating wheels often evaluate potential suppliers based on their reputation, technological expertise, and ability to provide timely support.

In conclusion, the role of centerless grinder regulating wheels manufacturers is vital in the manufacturing industry. Their commitment to quality, customization, and sustainability significantly enhances the efficiency of the grinding process. As industries continue to demand high-performance solutions, these manufacturers will play an essential role in driving innovation and meeting the evolving needs of their customers. For businesses seeking to optimize their grinding operations, partnering with a reliable regulating wheel manufacturer can lead to significant improvements in productivity and product quality.