Understanding Centerless OD Grinder Pricing A Comprehensive Overview

In today's fast-paced manufacturing environment, efficiency and precision are paramount. One of the essential machines in achieving these goals is the centerless outer diameter (OD) grinder. This powerful tool is primarily used for grinding cylindrical parts without the need for a complex setup. As industries continue to seek high-quality components, understanding the pricing of centerless OD grinders becomes crucial for businesses aiming to invest in this technology.

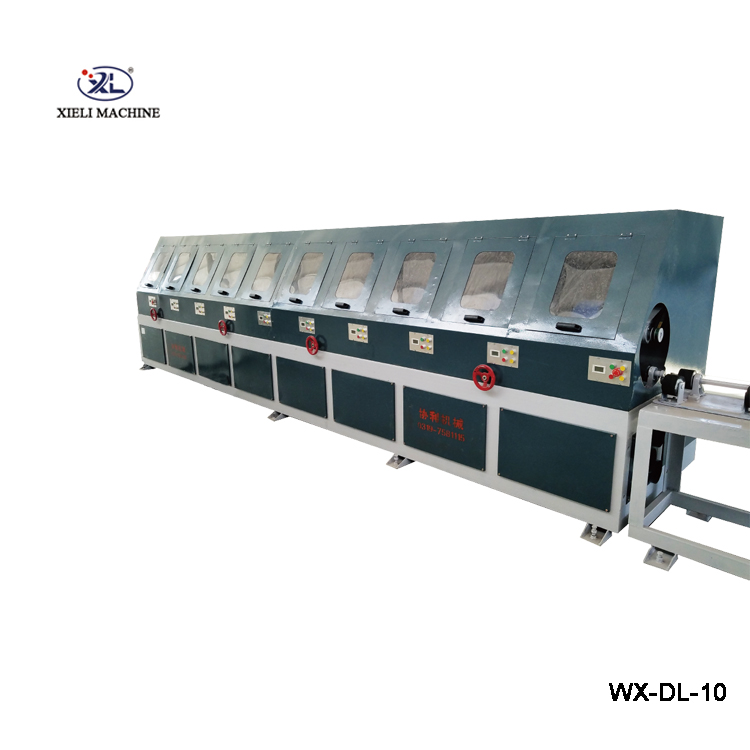

What is a Centerless OD Grinder?

A centerless OD grinder is a machine that allows for the grinding of cylindrical parts without requiring the workpiece to be centered between two points. Instead, it uses a fixed grinding wheel and a regulating wheel to hold and rotate the workpiece. This design enables higher production rates, improved accuracy, and reduced labor costs compared to traditional grinding methods.

Factors Influencing Centerless OD Grinder Prices

When considering the purchase of a centerless OD grinder, several factors influence the price of these machines

1. Type of Grinder There are generally two types of centerless grinders infeed and through-feed. Infeed grinders are suitable for complex parts, while through-feed grinders work best for simple, cylindrical components. The complexity and capability of the machine will significantly affect the price.

2. Size and Capacity The size of the grinder and its capacity for handling various part dimensions directly impact the cost. Larger machines capable of processing bigger parts or heavier workloads typically come at a higher price point.

3. Precision and Features Advanced features such as CNC controls, automated loading systems, and enhanced precision capabilities significantly elevate the cost. Machines with higher tolerances and automated features can offer improved productivity and consistent quality, justifying their price.

4. Brand and Reliability Established brands often command higher prices due to their reputation for reliability, service support, and quality. Investing in a well-regarded brand can lead to lower long-term costs and increased satisfaction.

5. New vs. Used New machines come with the latest technology and warranties but at a premium cost. Used machines, while more affordable, may pose risks regarding maintenance and performance longevity.

Typical Pricing Ranges

centerless od grinder pricelist

When examining the market, prices for centerless OD grinders can vary widely based on the aforementioned factors. On average, you can expect the following price ranges

- Entry-Level Models These machines, suitable for smaller operations or less demanding tasks, typically range from $20,000 to $40,000. They may lack advanced features but are adequate for basic grinding needs.

- Mid-Range Models A step up in sophistication, mid-range models often fall between $40,000 and $100,000. These machines offer better precision and additional features, making them suitable for more nuanced applications.

- High-End Machines For advanced manufacturing facilities requiring state-of-the-art technology, high-end centerless OD grinders can cost anywhere from $100,000 to over $250,000. These models include features like fully automated systems, high-speed grinding capabilities, and top-tier precision.

Considerations When Purchasing

Before making an investment in a centerless OD grinder, companies should conduct thorough research and consider the following

- Operational Needs Assess your production volume and the specific characteristics of the parts you need to grind. This evaluation ensures you choose a grinder that aligns with your operational requirements.

- Budget Constraints Establish a clear budget that considers not just the purchase price, but also potential maintenance costs, training for staff, and any additional tooling needed.

- Future Proofing Consider the longevity of the machine and whether it will accommodate future production needs. Investing in a model with scalable features may save costs in the long run.

Conclusion

Investing in a centerless OD grinder is a significant decision that can impact a company’s efficiency and output quality. Understanding the pricing structure and what influences these costs will enable businesses to make informed choices that align with their manufacturing goals. Whether opting for a new or used machine, focusing on the right features, brand reputation, and operational needs will enhance productivity and profitability in the competitive manufacturing landscape.