The Importance of Tube Internal Polishing Machines in Manufacturing

In the realm of manufacturing, particularly in industries such as aerospace, automotive, and chemical processing, the quality of metal tubes plays a critical role in the performance and longevity of the final products. One essential aspect of maintaining high-quality tubes is the internal surface finish, which can significantly affect flow characteristics, corrosion resistance, and overall strength. This is where tube internal polishing machines become indispensable.

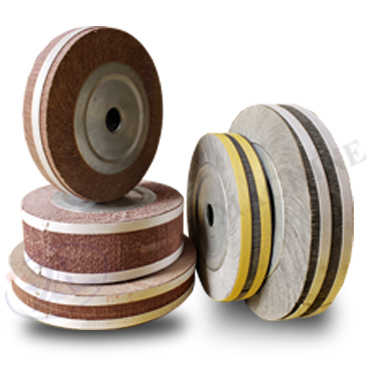

Tube internal polishing machines are specialized equipment designed to enhance the surface finish of tube interiors. These machines utilize various polishing techniques, including mechanical, chemical, and electrolytic processes, to remove burrs, scale, and other imperfections that can occur during the manufacturing process. The result is a smooth, polished inner surface that meets stringent industry standards.

The demand for high-quality tube internal polishing has led to the emergence of numerous factories dedicated to manufacturing these machines. These factories focus on innovation and efficiency, continually developing new technologies to improve the polishing process. For instance, automation has become a vital aspect of modern tube polishing machines, allowing for consistent results and reducing labor costs. Additionally, advancements in materials and design enable manufacturers to produce machines that are more durable and capable of handling a wider range of tube sizes and materials.

tube internal polishing machine factories

One of the key benefits of using tube internal polishing machines is their ability to enhance product performance. Polished tubes reduce friction, allowing for smoother fluid flow, which is especially crucial in hydraulic systems and pipelines. Furthermore, a smooth internal surface minimizes the risk of corrosion, extending the lifespan of the tubes and reducing maintenance costs. This is particularly important in industries where tube integrity is crucial for safety and efficiency.

Moreover, the role of tube internal polishing machines extends beyond mere aesthetics. Regulatory compliance is paramount in many sectors, and polished tubes are often required to meet specific standards. By investing in high-quality polishing equipment, manufacturers can ensure that their products not only meet but exceed these regulatory requirements.

In summary, tube internal polishing machines are a vital component of modern manufacturing processes. They play a crucial role in enhancing the quality and performance of metal tubes, thus contributing to the overall efficiency and safety of various industries. As technology continues to advance, the factories producing these machines are poised to lead the charge in delivering innovative solutions that meet the evolving needs of manufacturers worldwide.