Square Tube Grinding Machine Supplier Elevating Precision in Metal Fabrication

In the ever-evolving world of metal fabrication, the need for high-quality equipment is paramount. Among the numerous tools available, square tube grinding machines have gained significant importance due to their ability to enhance precision and efficiency in the production process. This article explores the role of square tube grinding machine suppliers, the advantages of their products, and the factors to consider when selecting a supplier.

Understanding Square Tube Grinding Machines

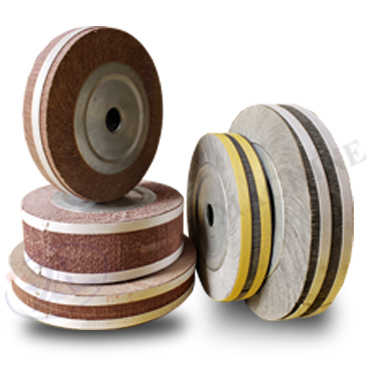

Square tube grinding machines are specialized equipment designed to grind and polish the surfaces of square tubes. These machines play a critical role in various industries, including construction, automotive, and furniture manufacturing. By removing imperfections, such as burrs, and achieving a smooth finish, these machines ensure that the final products meet the highest standards of quality and aesthetics.

Advantages of Investing in Quality Grinding Machines

1. Precision and Consistency One of the primary benefits of using a square tube grinding machine is the precision it offers. Advanced grinding machines can produce uniform finishes, ensuring consistency across batches. This level of precision is essential for manufacturers who rely on tight tolerances and exact specifications.

2. Time Efficiency Manual grinding and polishing can be time-consuming and labor-intensive. However, with the automation provided by modern grinding machines, companies can significantly reduce production time. This enhanced efficiency allows manufacturers to focus on other critical aspects of their operations, ultimately improving productivity.

3. Cost-Effectiveness While the initial investment in high-quality grinding equipment may seem substantial, the long-term savings can be significant. Quality machines reduce the need for rework, minimize material waste, and lower labor costs, leading to overall cost savings for manufacturing businesses.

4. Versatility Many square tube grinding machines come with adjustable features, allowing them to handle a variety of tasks. From grinding to polishing and even surface finishing, these machines can adapt to meet different production needs, making them a valuable addition to any workshop.

The Role of Suppliers in Metal Fabrication

square tube grinding machine supplier

A reliable square tube grinding machine supplier is essential to ensure that manufacturers have access to the best equipment and support. Suppliers not only provide the machines themselves but often offer additional services such as maintenance, repairs, and technical support. By partnering with a reputable supplier, manufacturers can enhance their operational efficiency and avoid potential production delays caused by equipment failures.

Choosing the Right Supplier

When selecting a square tube grinding machine supplier, several factors should be considered

1. Product Quality The quality of the machines is perhaps the most crucial factor. It’s essential to research suppliers who offer machines built with high-grade materials and advanced technology to ensure longevity and performance.

2. Reputation and Experience A supplier’s reputation in the industry can often indicate the reliability and quality of their products. Look for suppliers with a proven track record and positive customer reviews.

3. Customer Support Excellent customer service is vital. A good supplier should offer comprehensive support, including installation assistance, training, and prompt maintenance services.

4. Range of Products Assess whether the supplier offers a variety of models and configurations. This variety allows businesses to choose machines that best suit their specific production requirements.

5. Pricing and Financing Options While price shouldn’t be the only consideration, it is essential to find a supplier who provides competitive pricing without compromising on quality. Additionally, inquire about financing options that may assist in making the investment more manageable.

Conclusion

In the competitive landscape of metal fabrication, having access to advanced square tube grinding machines is crucial for maintaining an edge in quality and efficiency. Partnering with a reliable square tube grinding machine supplier can significantly enhance a manufacturer’s capabilities, enabling them to meet market demands with precision. By considering factors such as product quality, supplier reputation, customer support, product range, and pricing, businesses can select the best supplier to support their operational needs. Investing in the right equipment and supplier not only streamlines production but also paves the way for future growth and innovation in the industry.