Understanding CNC Centerless Grinder Factories

In the modern manufacturing landscape, CNC (Computer Numerical Control) technology has revolutionized precision machining, enabling manufacturers to achieve high levels of accuracy and efficiency. Among the various CNC machines, centerless grinders play a crucial role in the production of cylindrical components. In this article, we will explore the significance of CNC centerless grinder factories, the technology behind them, and the benefits they provide to manufacturers across different industries.

What is a CNC Centerless Grinder?

A CNC centerless grinder is a type of grinding machine that uses a unique setup to grind cylindrical parts without the need for the part to be held between centers. Instead, the workpiece is supported by a work blade and positioned between two rotating grinding wheels – the grinding wheel and the regulating wheel. This configuration allows for efficient and continuous grinding, making it an ideal choice for mass production of cylindrical components.

The Technology Behind CNC Centerless Grinders

CNC centerless grinders utilize advanced software and control systems that enable precise adjustments and monitoring throughout the grinding process. These machines can be programmed to execute complex grinding sequences with high repeatability, ensuring consistent quality across production runs. The integration of CNC technology allows manufacturers to automate the grinding process, reducing labor costs and minimizing human error.

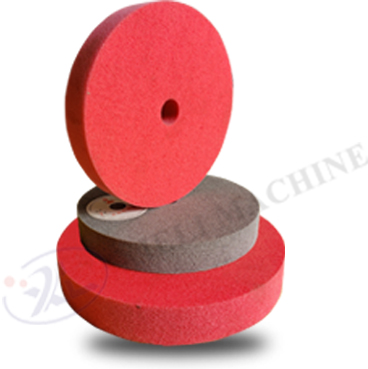

Many modern centerless grinders are equipped with features such as in-process gauging, which provides real-time feedback on workpiece dimensions. This capability enables quick adjustments, ensuring that the grinding process adheres strictly to specifications. Additionally, the use of high-quality diamond or CBN (Cubic Boron Nitride) wheels enhances the grinding performance and extends the lifespan of the grinding tools.

Benefits of CNC Centerless Grinder Factories

cnc centerless grinder factories

CNC centerless grinder factories offer several key advantages that contribute to their growing popularity

1. Increased Precision The CNC technology enables tighter tolerances and better surface finishes compared to traditional grinding methods. This precision is essential in industries such as automotive, aerospace, and medical devices, where component quality is critical.

2. Higher Productivity The efficiency of centerless grinding allows for rapid material removal and reduced cycle times. This high throughput is particularly beneficial for manufacturers producing large volumes of components, as it leads to significant cost savings and improved resource management.

3. Versatility CNC centerless grinders can handle a wide variety of materials, including metals, plastics, and composites. The ability to work with different materials makes them a versatile choice for diverse manufacturing needs.

4. Reduced Setup Times With CNC programming, setup times can be drastically reduced as machines can be quickly reconfigured for different parts. This flexibility allows factories to respond more rapidly to changing market demands.

5. Improved Quality Control The integration of automation and real-time monitoring systems in CNC centerless grinders enhances quality control and assures compliance with stringent industry standards.

Conclusion

CNC centerless grinder factories represent a significant advancement in the field of manufacturing. By harnessing the power of CNC technology, these factories are able to produce high-quality cylindrical components with remarkable efficiency and precision. As industries continue to evolve and the demand for tighter tolerances and higher productivity grows, CNC centerless grinders will undoubtedly play an increasingly important role in shaping the future of manufacturing. Companies that invest in these technologies will not only enhance their competitive edge but also position themselves to meet the challenges of tomorrow’s markets.