Centerless Grinding on Surface Grinder A Comprehensive Overview

Centerless grinding is a manufacturing process that allows for the efficient and precise machining of workpieces. Unlike traditional grinding methods that require the use of a fixture to hold the workpiece, centerless grinding utilizes a different approach that simplifies the operation and enhances productivity. This article explores the principles of centerless grinding, its application on surface grinders, and the advantages it offers, particularly focusing on supplier options available in the market.

Understanding Centerless Grinding

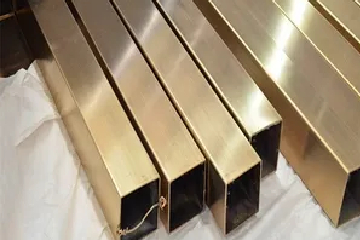

In centerless grinding, the workpiece is positioned between two wheels the grinding wheel and the regulating wheel. The grinding wheel is responsible for material removal, while the regulating wheel controls the speed and feed of the workpiece. This design eliminates the need for a specific set-up, allowing for continuous feed of multiple workpieces. Centerless grinding is particularly effective for cylindrical parts and is widely used in the manufacturing of components like shafts, rods, and pins.

Using Surface Grinders for Centerless Grinding

Surface grinders are typically used for producing flat surfaces, but they can also be adapted for centerless grinding applications. By configuring a surface grinder to accommodate centerless setups, manufacturers can enhance their production capabilities without the need for significant equipment investment. This adaptability makes surface grinders a valuable tool in various machining environments.

Advantages of Centerless Grinding on Surface Grinders

centerless grinding on surface grinder supplier

1. High Precision and Tolerance One of the primary benefits of centerless grinding is the ability to achieve high levels of precision. This method allows manufacturers to maintain tight tolerances on component dimensions, which is crucial in industries such as aerospace and automotive.

2. Increased Productivity Centerless grinding provides significant reductions in cycle time due to its continuous operation. Workpieces can be fed through the system without being retrieved and replaced, streamlining the production process and improving efficiency.

3. Versatility While surface grinders are usually associated with flat surface finishes, their adaptation to centerless grinding allows for versatility in processing. Manufacturers can tackle a range of workpieces, from simple shapes to complex geometries.

4. Cost-Effectiveness Utilizing existing surface grinding machines for centerless operations can be a cost-effective solution for manufacturers. This approach reduces the capital expenditure related to purchasing specialized centerless grinding equipment.

Choosing a Reliable Supplier

When considering centerless grinding solutions using surface grinders, selecting the right supplier is essential. A reputable supplier will offer quality machinery, necessary attachments, and ongoing support services to ensure the grinding process runs smoothly. Look for suppliers with a solid track record, positive customer feedback, and comprehensive service packages.

In conclusion, centerless grinding on surface grinders presents a unique opportunity for manufacturers to enhance their machining capabilities. By understanding the principles, benefits, and supplier options available in the market, businesses can make informed decisions that ultimately lead to improved product quality and operational efficiency. Whether for small-scale production or large manufacturing environments, adapting surface grinders for centerless operations can be a strategic move in today's competitive landscape.