Navigating the intricate world of precision manufacturing often leads industry professionals to a crucial tool the micro centerless grinder. This equipment, indispensable in many production lines, plays a pivotal role in refining small parts to exact specifications. Among its many applications, the micro centerless grinder is acclaimed for its ability to produce parts with low tolerances and exceptional surface finishes.

Manufacturers value micro centerless grinders for their remarkable efficiency and precision. These machines work without the need for a traditional spindle or fixture, which drastically reduces downtime between production runs. Despite their small size, these grinders are both robust and adaptable, easily integrating into existing workflows. Their design eliminates the need for centering the workpiece, easing the process for operators while simultaneously heightening productivity.

Expertise is paramount when dealing with micro centerless grinders. Operators must understand both the mechanics and subtleties of the grinding process. The machine functions by utilizing two rotary wheels—one stationary, the other regulating the speed of the component's rotation—to grind away excess material, achieving the desired dimensions. Experience reveals that maintaining optimal wheel speeds and implementing precise adjustments is crucial for the seamless operation of the grinder. This level of precision ensures the production of micro parts that meet the exacting standards required by industries ranging from aerospace to medical devices.

One of the main advantages of a micro centerless grinder is its ability to handle a wide range of materials, including hard and soft metals, polymers, and ceramics. This versatility opens opportunities for manufacturers to cater to various sectors without extensive equipment modifications. Yet, working with different materials requires a deep understanding of their unique properties. It's essential to select the correct abrasive types and ensure that the machine is configured accordingly. This deep knowledge underscores the importance of expertise in achieving perfect outcomes every time.

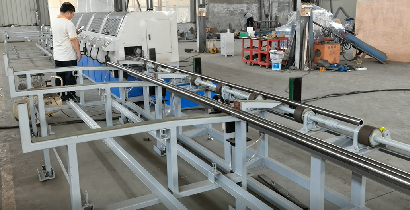

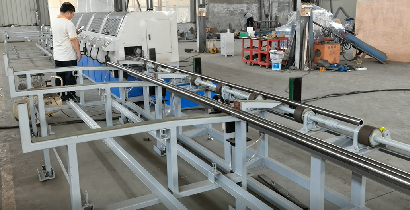

micro centerless grinder

In terms of authoritativeness, companies specializing in micro centerless grinding often lead the industry in innovation. They continuously refine techniques to enhance machine capabilities and cater to the ever-evolving needs of modern production. The wealth of knowledge accumulated over years of specialization empowers these companies to offer unparalleled guidance and solutions, solidifying their role as industry leaders. As a result, manufacturers can rely on these experts not only for high-quality machinery but also for insights that can revolutionize their production processes.

The trustworthiness of a micro centerless grinder depends heavily on both the machine's build quality and the reputation of the manufacturer. Leading brands commit to rigorous testing protocols, ensuring that each unit meets stringent industry standards. They also provide comprehensive after-sales support, including training and maintenance services, ensuring that their machines operate flawlessly throughout their lifecycle. Such commitments build trust, giving users the confidence that their investment will yield long-term returns through consistent performance and minimal downtime.

Furthermore,

constant technological advancements are shaping the future of micro centerless grinding. Innovations such as automated control systems and real-time feedback mechanisms are being integrated into modern machinery. These enhancements not only boost precision and ease of use but also optimize overall efficiency in production environments. Manufacturers who adopt these cutting-edge solutions can expect significant improvements in both quality and throughput, maintaining their competitive edge in the industry.

In conclusion, the micro centerless grinder is more than just a piece of equipment; it’s a linchpin in precision manufacturing. Its capabilities in handling various materials, combined with the expertise required to operate and maintain it, underscore its value to the industry. Companies that invest in high-quality grinders benefit from improved efficiency, reduced waste, and the ability to produce components that meet the highest quality standards. In an age where precision and trustworthiness are crucial, micro centerless grinders offer the reliability and expertise that manufacturers need to succeed.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.