Navigating the realm of manufacturing demands precision, reliability, and efficiency, and centerless bar grinding machines stand as pivotal players in this exacting domain. Their ability to smooth and perfect metal surfaces makes them indispensable across diverse industries, from aerospace to automotive manufacturing. However, a question frequently faced by procurement professionals and production managers centers on cost—specifically, how to effectively navigate the pricelist of centerless bar grinding machines to achieve exceptional value without compromising operational effectiveness.

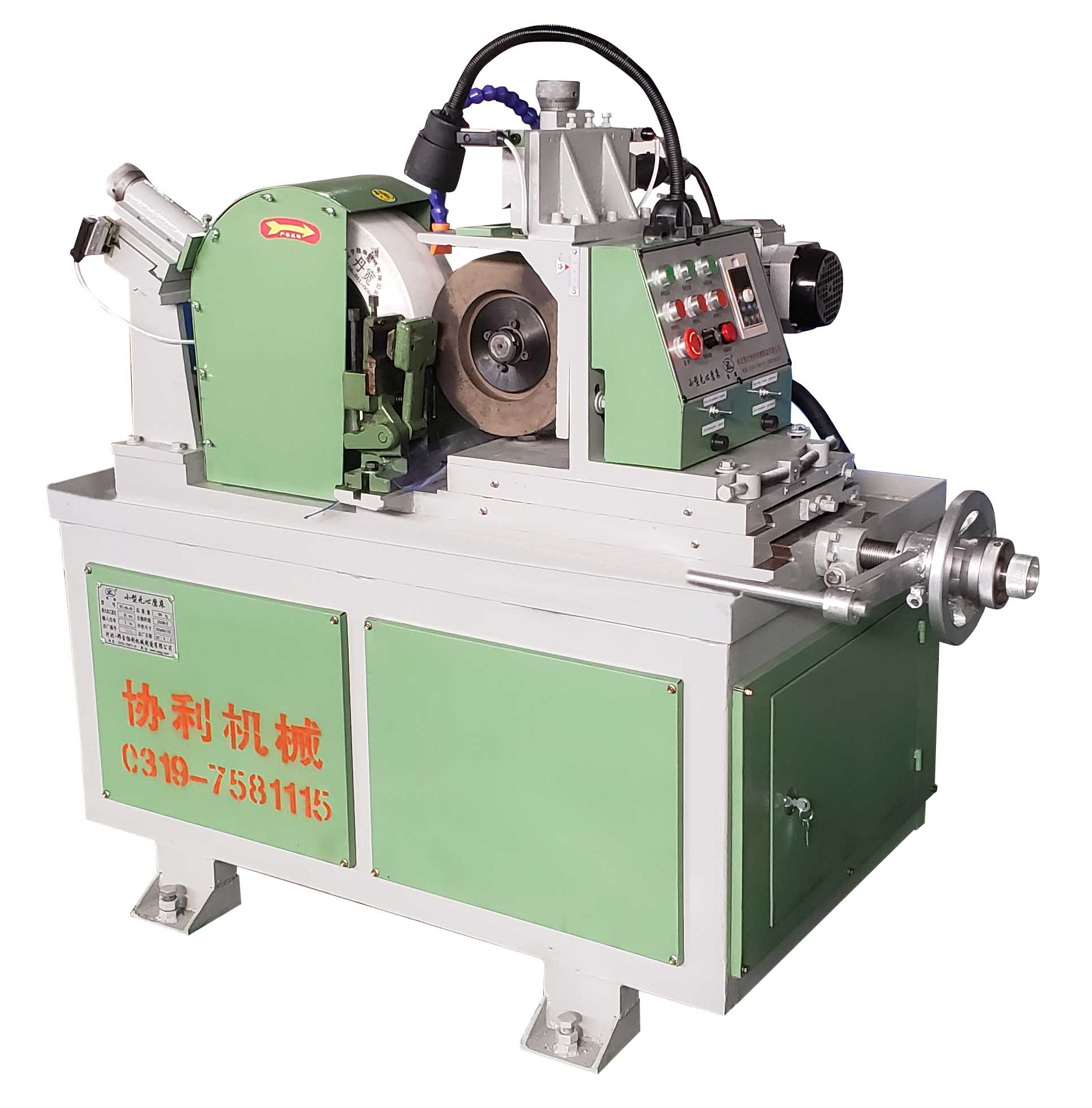

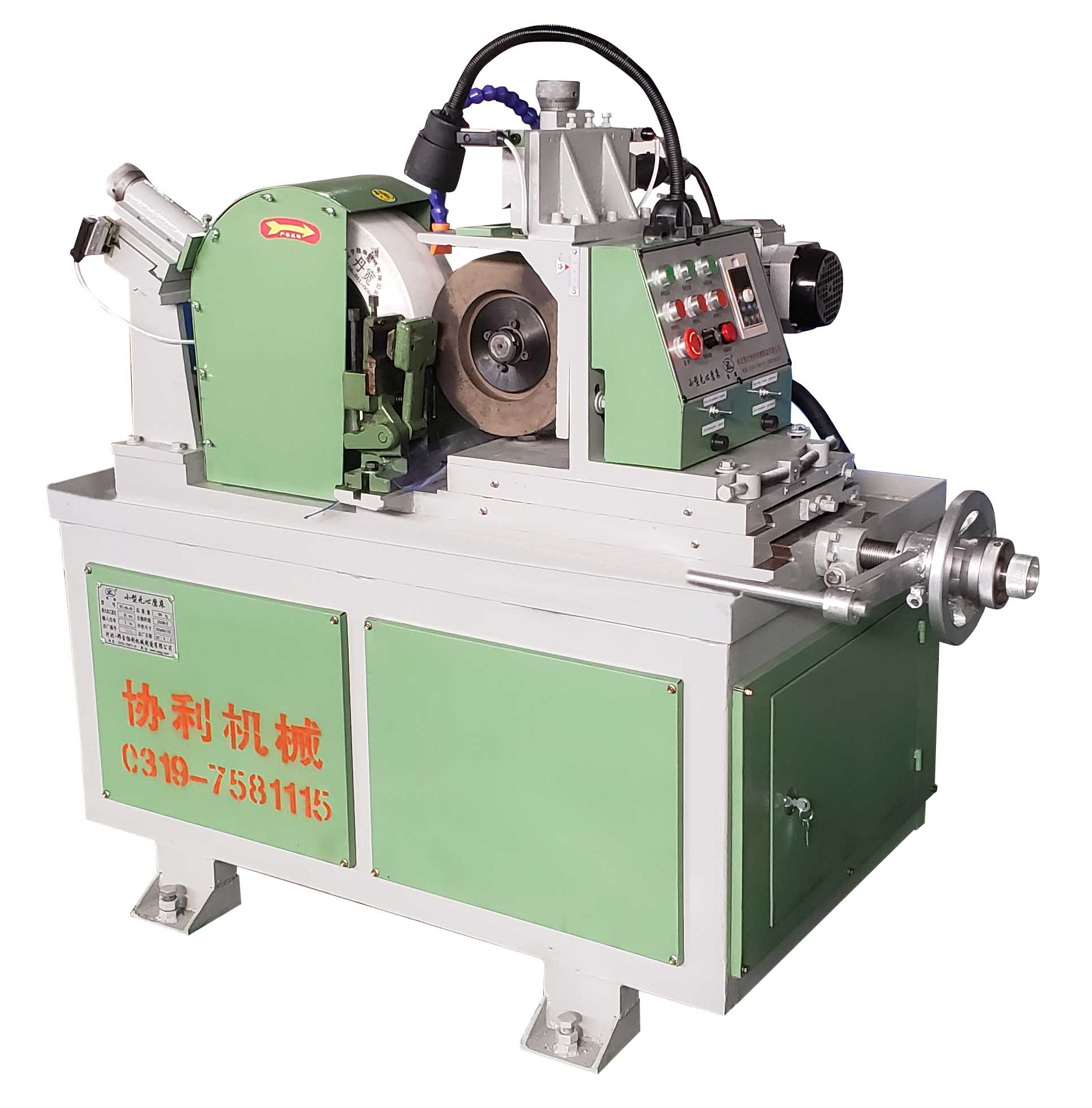

Understanding the complexities of centerless bar grinding machines starts with recognizing their core functions and design variations. These machines are designed for grinding exterior surfaces with high precision, eliminating the need for centers in the process. This not only reduces the setup time but also increases the speed of manufacturing high-precision bars. The various models available in the market range from manually operated units to fully automated systems equipped with advanced technological integration.

When combing through pricelists, awareness of key machine features and specifications can significantly influence your purchasing decision. Chiefly, the grinding wheel size, speed settings, automation level, and support technologies (such as CNC integration) are determinative factors. For instance, advanced models with computerized numerical control (CNC) capabilities allow for enhanced precision and repeatability, which can justify a higher initial expenditure through subsequent gains in productivity and decrease in material wastage.

Additionally, the durability and maintenance requirements of a machine significantly impact both its upfront cost and total cost of ownership. Machines constructed with reinforced frames and high-quality components offer prolonged lifespan and lesser downtime, crucial for maintaining consistent production cycles. A crucial parameter to check is the machine's ease of maintenance and the availability of spare parts, as these aspects directly affect the operational longevity and uninterrupted workflow.

centerless bar grinding machine pricelist

Another crucial element is the reputation and support offered by the manufacturer. Companies with a strong track record offer not just robust machinery, but also a guarantee of excellent post-purchase support. This includes training for operators, availability of technical assistance, and provision of detailed manuals. Investing slightly more with a reputable manufacturer can endow the buyer with peace of mind through comprehensive warranty terms and responsive after-sales service.

Lastly, when evaluating the pricelist, one must also factor in secondary costs such as installation, calibration, and potential downtime during the transition from an older system. Engaging with vendors to obtain a holistic cost estimation, including these aspects, provides a clearer picture of the investment requirement and helps in making an informed decision.

In essence, while the upfront pricing of centerless bar grinding machines can seem daunting, understanding the array of features and their impact on operational efficiency and cost-effectiveness is essential. Each model's value proposition extends beyond the initial purchase price, factoring into long-term benefits in speed, accuracy, and production volume. To make the investment truly beneficial, buyers should aim to align the machine’s functionalities with their specific manufacturing needs, thus ensuring a seamless integration within their production framework and yielding substantial returns on investment.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.