The Importance of Centerless Grinder Regulating Wheels Choosing the Right Supplier

In the world of precision machining, centerless grinding plays a crucial role in achieving exact dimensions and surface finishes on cylindrical components. The efficiency and effectiveness of this process greatly depend on the quality of the regulating wheels used in the grinding machines. Therefore, selecting the right supplier for centerless grinder regulating wheels is pivotal for manufacturers aiming to maintain high production standards.

Centerless grinding involves the grinding of the workpiece without the necessity of holding it in place by chucks or fixtures. Instead, the workpiece is supported by a regulating wheel while being grinded by an abrasive wheel. The regulating wheel not only contributes to the grinding process but also controls the speed and movement of the workpiece. For this reason, the quality, material, and design of the regulating wheels are of utmost importance.

One of the first factors to consider when choosing a supplier for centerless grinder regulating wheels is their experience and reputation in the industry. A supplier who has been around for a substantial amount of time will likely have a better understanding of diverse customer needs and the nuances of different grinding applications. Additionally, a reputable supplier will usually provide genuine feedback and testimonials from clients that can guide you in your decision-making process.

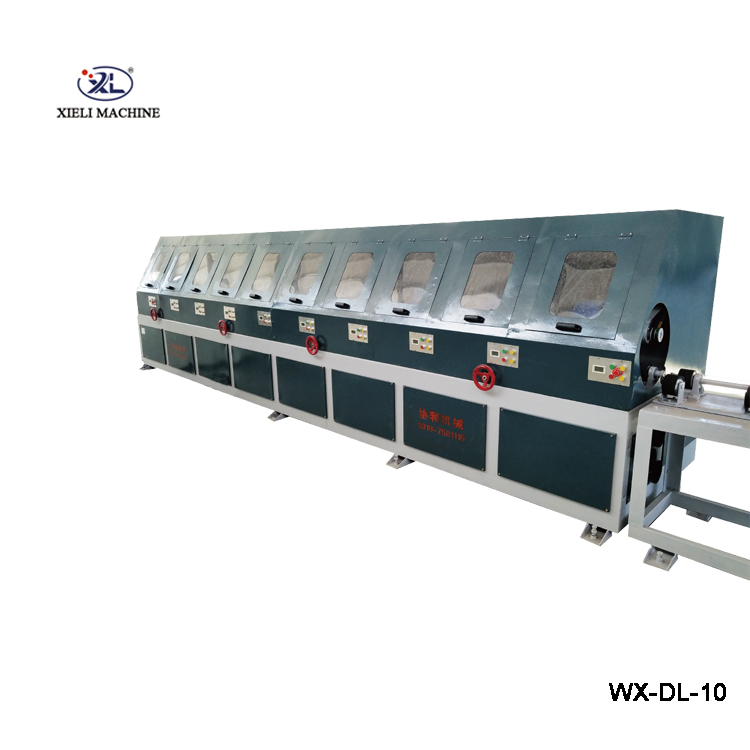

centerless grinder regulating wheels supplier

The quality of materials used in manufacturing regulating wheels is another critical aspect. High-quality wheels are typically made from durable materials that ensure longevity and performance consistency. A reliable supplier will offer wheels made from advanced composites or rubber compounds that are specifically designed for high-precision grinding applications. By opting for a supplier who focuses on innovative materials and technology, manufacturers can enhance their production capabilities and reduce downtime caused by wheel wear.

Furthermore, customizability is a significant consideration. Different applications require different specifications. A supplier that provides options for customization—such as varying diameters, hardness levels, and bonding types—can cater to specific customer needs, leading to better grinding efficiency and product quality. Custom solutions also allow manufacturers to optimize their machining processes and achieve desired outcomes without compromising on operational efficiency.

Additionally, it’s essential to evaluate the level of customer support and after-sales service provided by the supplier. A good supplier should be able to offer technical assistance, guidance on wheel selection, and efficient handling of any issues that might arise during machining processes.

In conclusion, the supplier of centerless grinder regulating wheels can significantly influence the performance, efficiency, and overall production quality of machining operations. By considering industry experience, material quality, customization options, and customer support, manufacturers can make informed decisions that align with their operational goals. Ultimately, investing in high-quality regulating wheels from an esteemed supplier leads to enhanced productivity and greater satisfaction in the centerless grinding process.