Navigating the intricate world of belt sander polishing machines requires more than just a fundamental understanding; it demands precise expertise and authoritative insight to ensure the best match for any industrial application. Factories today need equipment that not only promises efficiency but also exudes reliability and precision to cater to rigorous demands. Here, we delve into the multifaceted universe of belt sander polishing machines, exploring the technological advancements, operational efficiency, and strategic benefits that these machines offer to manufacturing environments.

The belt sander polishing machine stands out as a cornerstone in the realm of surface finishing tools. With the rising demand for precision engineering, factories must equip themselves with machines capable of delivering high-quality results consistently. These machines, operating on the principle of abrasion, utilize a continuous loop of sandpaper to smooth the surface of various materials, thus ensuring a refined finish.

One critical aspect of these machines is their adaptability. Depending on the requirement, they can be fitted with a variety of belts designed for different levels of coarseness. This adaptability allows factories to customize their operations, tailoring the machine's functionality to the specific needs of the task at hand. From coarse grinding to fine polishing, belt sander polishing machines can handle a wide array of materials – metals, woods, plastics – making them indispensable in diverse industrial landscapes.

The technological advancements in recent years have significantly enhanced the efficacy and safety of these machines. Innovations like dust extraction systems have revolutionized the working environment by reducing particulate matter, thereby not only ensuring operator safety but also extending the life of the machine. Furthermore, digital controls and automated features now enable more precise operations, reducing the margin of error and enhancing productivity.

A vital factor contributing to the effectiveness of belt sander polishing machines is their build quality. A robust construction ensures longevity and reliability, key elements in sustaining production lines. Factories must seek out manufacturers that adhere to stringent quality control protocols during the production phase. The use of high-grade materials in manufacturing the machine components, such as belts and motors, is crucial to withstand the demanding conditions of industrial use.

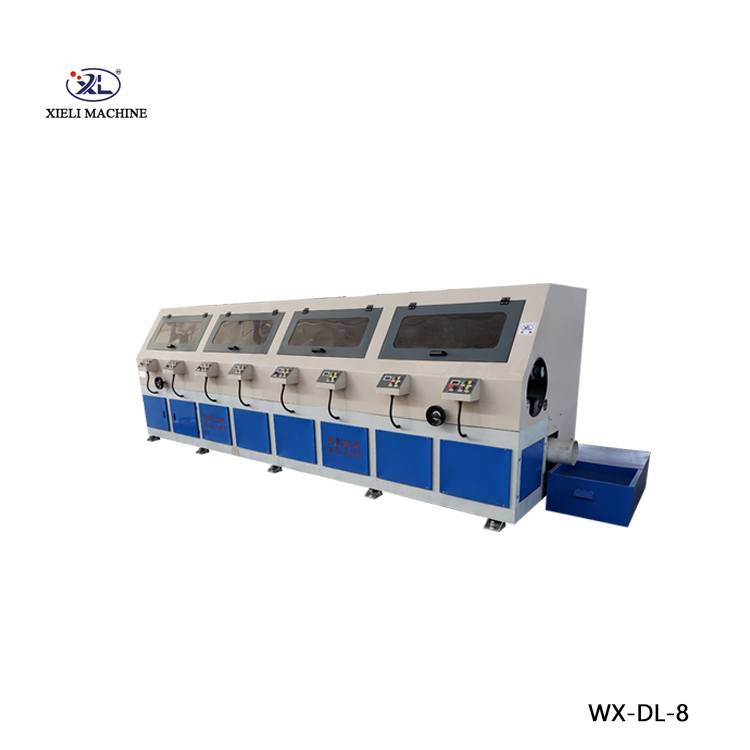

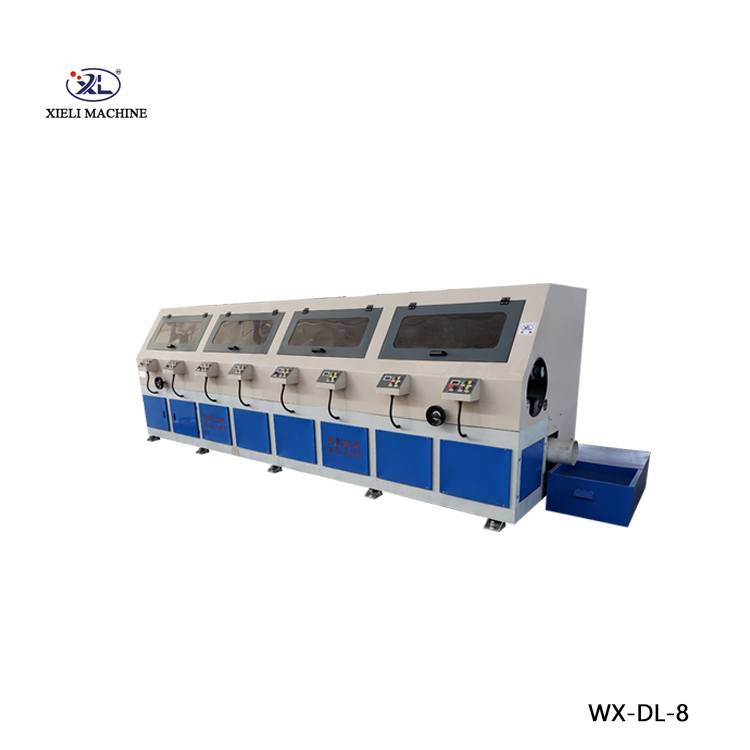

belt sander polishing machine factory

Expertise in handling and maintaining these machines is paramount. Operators must undergo comprehensive training to understand the nuances of machine operation and maintenance. Proper usage not only prolongs the machine's life but also optimizes performance. Regular maintenance checks should not be overlooked, as they play a critical role in ensuring the machine operates at its peak capacity without unexpected downtimes.

When selecting a belt sander polishing machine, factories must consider the reputability and reliability of the manufacturer. An experienced manufacturer brings years of innovation, feedback, and improvements to their designs, providing machines that are not only efficient but also backed by robust customer support. Trusted manufacturers often offer warranties, technical support, and spare parts, ensuring minimal disruption in operations if issues arise.

Industry certifications and standards are another measure of trustworthiness. Machines that comply with international safety and quality standards, such as ISO certifications, offer an assurance of quality and safety. These certifications reflect a commitment to maintaining exceptional design and production standards, which is crucial for establishing trust in the globally competitive arena.

Belt sander polishing machines are an investment. The correct choice can redefine efficiency and elevate the quality of production output. Harnessing the full potential of these machines is contingent upon an in-depth understanding of their capabilities and limitations, ensuring that factories can maximize their utility to enhance operational workflows.

In conclusion, a thorough grasp of the capabilities and technological nuances of belt sander polishing machines equips factories with the knowledge to make informed purchasing decisions. By aligning the machine's features with operational needs and ensuring rigorous training and maintenance routines, manufacturers can harness these powerful tools to achieve superior quality finishes and streamlined production processes. As industrial landscapes evolve, so must the machinery, with innovation and precision guiding the future of surface finishing.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.