Exploring the Market for Automatic Pipe Polishing Machine Exporters

In recent years, the global manufacturing landscape has witnessed considerable advancements, particularly in the field of metalworking and finishing technology. Among these innovations, the automatic pipe polishing machine has emerged as a pivotal tool for manufacturers involved in the production of various pipes and tubing. These machines offer a blend of efficiency, precision, and enhanced productivity, making them highly sought after in both domestic and international markets. This article delves into the significance, demand, and role of exporters of automatic pipe polishing machines.

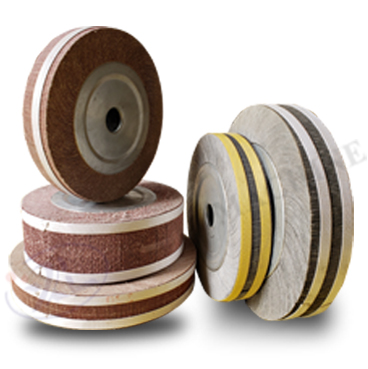

Automatic pipe polishing machines are designed to automate the polishing process, allowing for a flawless finish on pipes made from various materials, including stainless steel, aluminum, and copper. The primary advantage of using these machines is their ability to consistently produce high-quality finishes while minimizing labor costs. Traditional polishing methods can be time-consuming and subject to human error; however, automatic machines utilize advanced technology and precision controls to ensure uniform results. This has made them invaluable to industries such as construction, automotive, and aerospace, where both aesthetics and functionality are paramount.

The demand for these machines has surged with the growth of the industrial sector in emerging economies. Countries like China, India, and Brazil are ramping up their manufacturing capabilities, driving the need for efficient production tools. As enterprises expand, the requirement for high-quality polished pipes increases correspondingly. This market trend has incentivized exporters of automatic pipe polishing machines to enhance their offerings and reach a wider audience.

automatic pipe polishing machine exporters

One of the key factors propelling the growth of automatic pipe polishing machine exporters is the increasing emphasis on automation and operational efficiency. With businesses seeking to optimize their manufacturing processes, investing in automatic systems has become a strategic decision. Moreover, the trend towards sustainability and environmentally friendly practices is pushing manufacturers to adopt equipment that reduces waste and energy consumption. Automatic pipe polishing machines often come equipped with features that allow for better resource management, thereby appealing to a more environmentally conscious market.

Exporters who specialize in automatic pipe polishing machines play a crucial role in catering to diverse manufacturing needs. They not only supply quality machinery but also provide essential services such as installation, maintenance, and training. This comprehensive support ensures that clients can maximize the machine's capabilities, leading to improved productivity and cost savings.

Furthermore, as the global market continues to grow, it is imperative for exporters to stay abreast of technological advancements. Innovations such as intelligent controls, feedback systems, and integration with IoT are becoming more prevalent in the design of automatic pipe polishing machines. Companies that adopt and promote these technologies will likely gain a competitive edge in the marketplace.

In conclusion, the landscape for automatic pipe polishing machine exporters is flourishing, fueled by the increasing demand for high-quality industrial equipment. As manufacturers strive for efficiency, precision, and sustainability, the role of these exporters becomes ever more critical. By continuously evolving and adapting to market demands, they can ensure their position as leaders in this dynamic industry.