The Evolution and Benefits of Wholesale Supertec Centerless Grinders

In the realm of precision manufacturing, centerless grinders play a pivotal role in achieving the required tolerances and finishes for various metal components. Among the leading players in the market, Supertec stands out with its robust line of centerless grinding machines designed for high efficiency and precision. This article delves into the importance of wholesale Supertec centerless grinders, their applications, and the benefits that make them a preferred choice in the industry.

Understanding Centerless Grinding

Centerless grinding is a machining process utilized to grind cylindrical workpieces without the need for a fixed center. Unlike traditional grinding methods where the workpiece is mounted between two centers, centerless grinding relies on a combination of regulating and grinding wheels that rotate at varying speeds. This unique setup allows for the continuous feed of material, leading to significant productivity gains.

The Supertec Advantage

Supertec machinery is renowned for its advanced engineering and manufacturing capabilities. Their centerless grinders are engineered to provide exceptional accuracy and surface finish, which is essential in industries such as automotive, aerospace, and electronics.

1. Precision Engineering Supertec grinders are equipped with high-quality components that ensure stability and precision during operation. The machines are designed to handle a diverse range of materials including steel, aluminum, and other metals, making them versatile options for manufacturers.

2. Increased Efficiency The wholesale aspect of Supertec centerless grinders means manufacturers can procure these machines at competitive prices. Buying in bulk can lead to negotiated contracts that include maintenance services and parts, maximizing the lifecycle of the equipment.

3. Adaptable Technology Today’s Supertec grinders are equipped with advanced CNC technology, enabling manufacturers to program intricate grinding sequences, thus reducing the risk of human error and enhancing production consistency. The adaptability of these machines allows them to be used in both high-volume production runs and smaller batch jobs.

Applications Across Industries

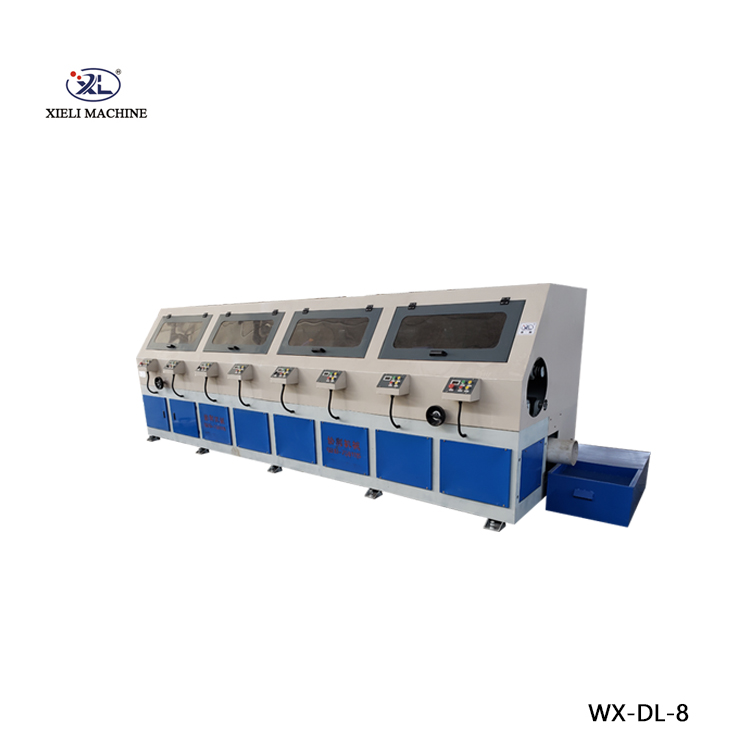

wholesale supertec centerless grinder

The applications for centerless grinding are vast and varied. Industries that frequently utilize Supertec centerless grinders include

- Automotive With the need for precision components such as shafts, bearings, and pins, the automotive sector relies heavily on centerless grinding to maintain performance standards and safety regulations

.- Aerospace Components used in aircraft require an exact fit and finish, making centerless grinding an indispensable process in this highly regulated industry.

- Medical Devices The medical field demands high precision for implants and surgical instruments. Supertec grinders ensure components meet stringent quality requirements.

- Electronics In the production of electronic components, precision is crucial to ensure reliability and function, making centerless grinding a key process.

Cost-Effectiveness and Reliability

Investing in wholesale Supertec centerless grinders equates to long-term cost savings for manufacturers. The machines are built for reliability and durability, reducing the need for frequent replacements or extensive repairs. Additionally, the reduction in cycle times due to the efficient grinding process translates to lower operational costs.

Moreover, the availability of technical support and training from Supertec ensures that operators are well-equipped to maximize the machines' potential. This support helps minimize downtime, further enhancing productivity and profitability.

Conclusion

In conclusion, wholesale Supertec centerless grinders represent a key investment for manufacturers seeking precision, efficiency, and adaptability in their grinding processes. Their unmatched capabilities in various industries and the potential for cost savings position them as invaluable tools in modern manufacturing. As the demand for precision-engineered components continues to rise, investing in reliable and advanced machinery like Supertec's centerless grinders will undoubtedly serve as a competitive advantage in any production environment. The journey toward manufacturing excellence is paved with the right tools, and Supertec is at the forefront, ready to lead the way.