For discerning manufacturers seeking to enhance their production capabilities, the Viking centerless grinder emerges as a transformative piece of machinery. Renowned for its precision, robust design, and versatility, this grinder is a staple in the metalworking industry. Selecting the right manufacturer to purchase from is a critical decision that influences your operational efficiency and product quality.

This article dives into why the Viking centerless grinder stands out, and what to consider when choosing a reliable manufacturer for your purchase.

The Viking centerless grinder is engineered to facilitate high-precision grinding operations, offering unparalleled excellence in surface finishing. Its advanced technology allows for consistent results with minimal deviation, ensuring each component processed meets exact specifications. This level of precision is indispensable in industries where exact tolerances are non-negotiable and can significantly reduce waste and rework costs.

Designed for durability, the Viking grinder boasts a heavy-duty construction that withstands the rigors of intensive manufacturing environments. Its robust design minimizes the need for frequent maintenance, thereby reducing downtime and contributing to a more streamlined production process. This robust construction not only ensures longevity but also maintains performance consistency over time, making it a cost-effective long-term investment.

Versatility is another distinguishing feature of the Viking centerless grinder. It can handle a wide range of materials—from various metals to composite materials—with ease. This adaptability is crucial for manufacturers that need to cater to diverse customer requirements or produce an array of products. The machinery’s flexibility ensures that you can quickly pivot operations without compromising on quality.

Precision, durability, and versatility are just part of the equation when investing in a centerless grinder; choosing the right manufacturer ensures you capitalize fully on these benefits. A reputable manufacturer not only provides high-quality equipment but also offers comprehensive support services. This includes detailed user training, which empowers your team to operate the grinder efficiently and effectively, optimizing your workflow and minimizing the risk of operator error.

Additionally, attentive after-sales support can greatly impact your machine's performance. A manufacturer should offer prompt responses and solutions to any technical issues that might emerge, safeguarding your operational continuity. When evaluating potential manufacturers, consider their reputation in the industry, customer feedback, and the breadth of their support services.

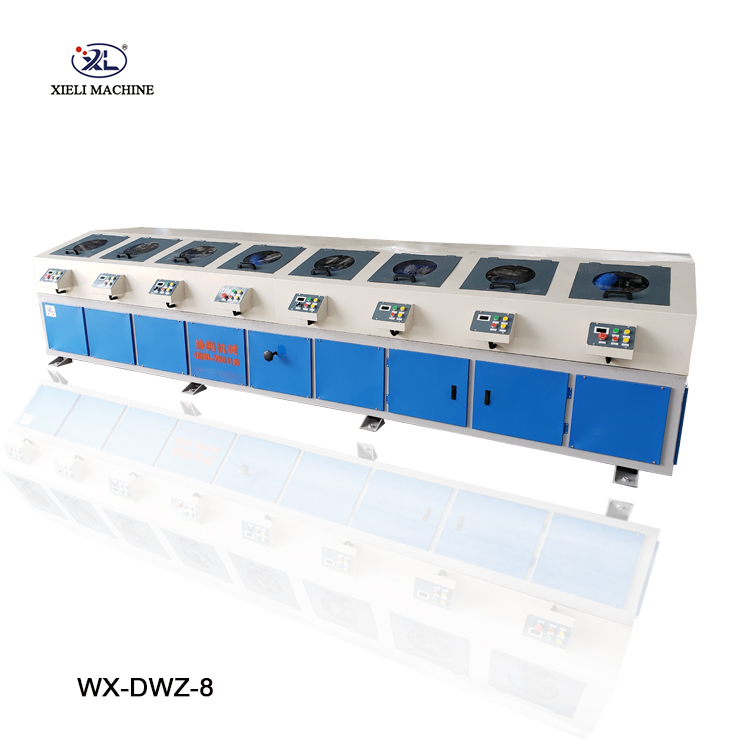

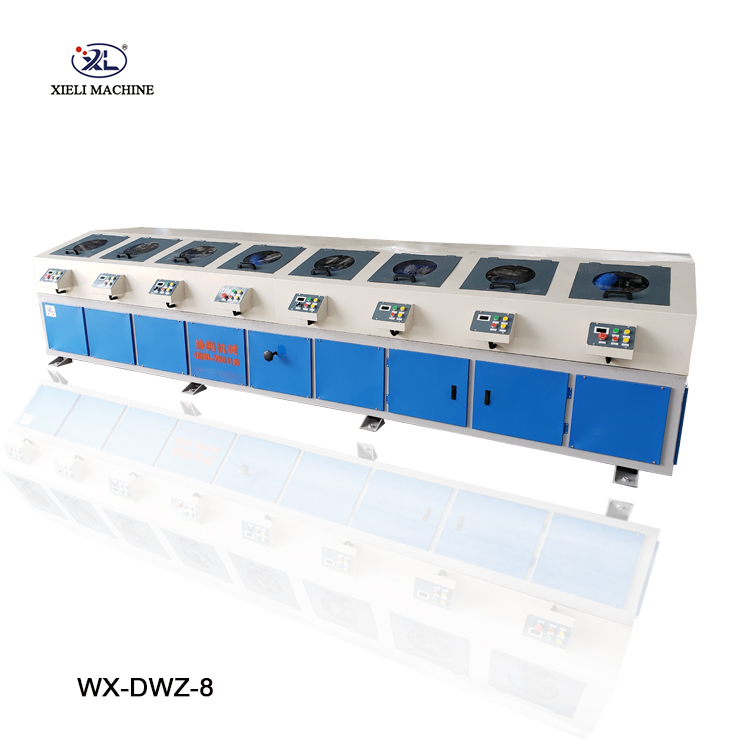

viking centerless grinder for sale manufacturer

Another factor to scrutinize is the manufacturer’s commitment to continuous improvement and innovation. The metalworking industry is fast-evolving, and aligning with a manufacturer that prioritizes technological advancements can provide a competitive edge. This ensures that your Viking centerless grinder is not only top-of-the-line at the point of purchase but evolves with advancements in technology to meet future demands.

Cost is always a factor, yet it’s vital to discern the value proposition offered. The most cost-effective solution isn’t necessarily the cheapest option; rather, it’s the one that combines competitive pricing with superior machine quality and reliable support. Weighing initial cost against long-term benefits such as durability, productivity improvements, and operational efficiencies is crucial for making an informed decision.

Trustworthiness of the manufacturer can be verified by assessing certifications and adherence to industry standards. ISO certifications and compliance with safety and environmental regulations are indicators of a manufacturer’s dedication to quality and ethical standards. Engaging with industry forums, reading reviews and testimonials, and seeking peer recommendations can further affirm the credibility of the manufacturer.

Working with a manufacturer who invests in building relationships can significantly enhance your experience. A collaborative partnership can offer insights into optimizing machine use and tailoring solutions to your specific needs, leading to better performance outcomes.

In conclusion, the Viking centerless grinder is an asset for any manufacturing operation seeking precision, efficiency, and reliability. Investing in this machinery from a reputable manufacturer amplifies its inherent benefits. By carefully evaluating manufacturer expertise, support, innovation commitment, cost-value balance, and trustworthiness, businesses can make informed purchasing decisions that bolster their production capabilities and market competitiveness.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.