When seeking the perfect tube rust remover machine, understanding the features and benefits that directly impact productivity and longevity is essential. This intricate piece of machinery doesn't just promise aesthetics but also extends the life of tubes and pipes by effectively eradicating rust and oxidation, which are often detrimental to structural integrity.

Investing in a high-quality tube rust remover machine begins with recognizing the real-world experiences of users who have encountered similar challenges. Many industries, ranging from automotive to construction, have relied on these machines for their precision and efficiency. Operators consistently report that the right machine not only saves time but also significantly reduces costs associated with manual rust removal methods. An exemplary machine distinguishes itself through ease of use and the ability to handle different tube sizes and materials, enhancing its versatility and appeal in various industrial sectors.

From a professional standpoint, understanding the mechanics and science behind rust removal technologies is crucial. These machines often incorporate advanced technologies such as laser cleaning, abrasive blasting, or chemical rust removers. Laser rust removal, for example, uses high-intensity laser beams to vaporize rust without damaging the base material, offering a non-contact cleaning approach that ensures precision and reduces the risk of material degradation. Alternatively, abrasive blasting employs high-pressure streams of abrasive material to wear away rust, ideal for robust, heavy-duty applications. Professionals often weigh the benefits of each method based on specific project requirements, environmental considerations, and material types.

Authority in the field is established by manufacturers who demonstrate a history of quality and innovation. Companies with a track record of research and development, adherence to industry standards, and positive customer feedback are more likely to offer machines that deliver on their promises. Moreover, partnerships with industry experts and certification from relevant bodies further bolster a manufacturer’s credibility. Testimonials from engineers and professionals who extensively use these machines in demanding environments can provide insights into the reliability and performance of the machines, verifying the manufacturer's claims.

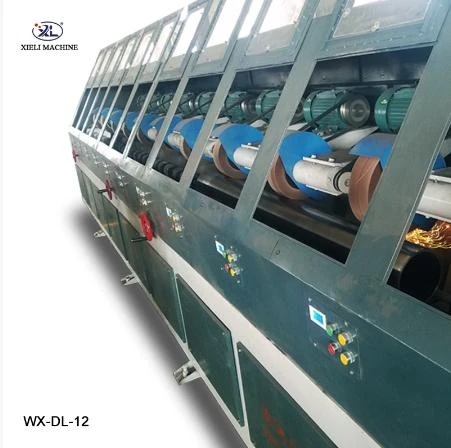

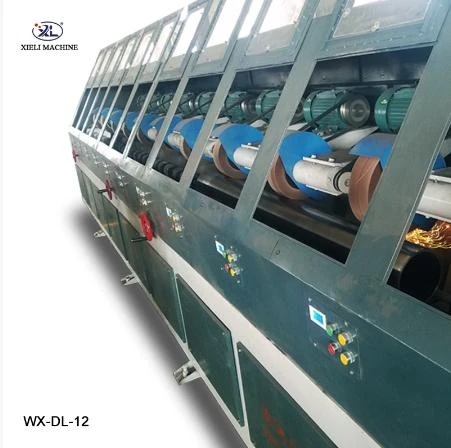

tube rust remover machine product

Trust in a tube rust remover machine is built upon demonstrable evidence of durability and consistent performance. Users should look for products with guarantees and comprehensive customer service support. Extended warranties, easy access to replacement parts, and technical support availability suggest that the manufacturer stands confidently behind their product. This trust extends beyond first-time buyers to seasoned professionals continually seeking to upgrade or maintain their equipment.

When choosing a tube rust remover machine, potential buyers must carefully evaluate the machine's flexibility and adaptability to different projects. Machines that allow for easy adjustment of settings to accommodate various tube dimensions and rust severity are particularly valuable. Assessing the ease of integrating these machines into existing workflows without extensive downtime or retraining is another critical factor influencing purchase decisions.

Finally, environmental sustainability is increasingly influencing purchasing choices. Machines that minimize energy consumption or do not produce harmful byproducts are gaining preference in industries looking to fulfill corporate social responsibility goals. Such machines not only contribute to a cleaner environment but also comply with stringent industry regulations regarding waste management and emissions.

In summary, the tube rust remover machine is an embodiment of modern engineering aimed at preserving both aesthetics and structural integrity. By emphasizing on experience, professional insights, authoritative endorsements, and proven reliability, this investment becomes indispensable for businesses aiming for efficiency and quality. Evaluating flexibility and sustainability further ensures that the chosen machine will serve as both an effective tool and a long-term asset.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.