Tube Polishing Machine Manufacturers in India An Overview

In recent years, the demand for tube polishing machines in India has witnessed significant growth, driven by various industries including automotive, aerospace, construction, and pharmaceuticals. These machines play a crucial role in achieving the desired aesthetic finish and surface quality on metal tubes, enhancing not only the appearance but also the functionality of the end products. This article explores the landscape of tube polishing machine manufacturers in India, highlighting key players, technological innovations, and market trends.

The Importance of Tube Polishing Machines

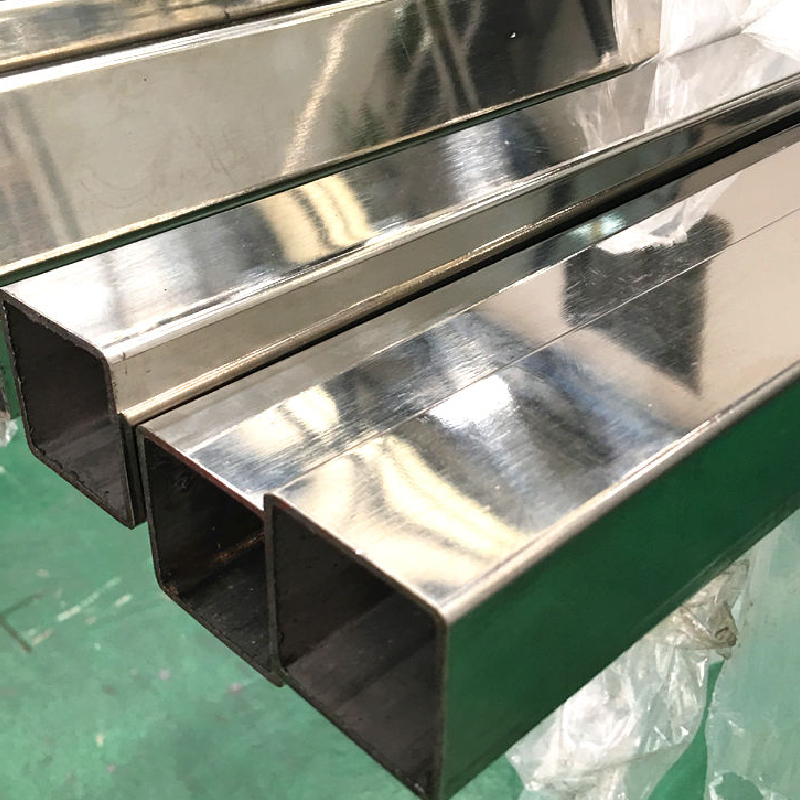

Tube polishing machines are essential for finishing metal tubes made from stainless steel, aluminum, brass, and other alloys. The polishing process removes surface imperfections, oxidation, and discoloration, resulting in a smooth, mirror-like finish. This is particularly important in industries where hygiene and aesthetics are paramount, such as food processing, pharmaceuticals, and decorative applications.

Key Players in the Indian Market

India is home to a diverse array of manufacturers specializing in tube polishing machines. Some of the notable players include

1. M/s. Jain Machine Tools Known for its extensive range of tube polishing machines that cater to various needs, Jain Machine Tools combines traditional craftsmanship with modern technology to deliver high-quality products.

2. Vijay Engineering This company focuses on innovative engineering solutions, providing specialized tube polishing machines designed for efficiency and durability. Their machines are well-regarded for their user-friendly interfaces and low maintenance requirements.

3. Dhanvanthri Engineering Offering a variety of polishing machines, Dhanvanthri Engineering stands out with its customized solutions tailored to meet specific industrial requirements.

4. Apex Engineering This manufacturer emphasizes producing machines that integrate advanced automation technologies, improving productivity and minimizing labor costs for customers.

These manufacturers are constantly innovating to enhance the performance and capabilities of tube polishing machines, ensuring they can meet the demands of a rapidly evolving market

.Technological Innovations

tube polishing machine india manufacturers

Recent advancements in technology have significantly improved the functionality of tube polishing machines. Manufacturers are now incorporating features such as

- Automated Control Systems Many modern machines come equipped with advanced control panels that allow operators to set precise parameters for polishing, ensuring consistent results.

- Variable Speed Motors These motors enable users to adjust the speed of the polishing process according to the material and desired finish, providing greater flexibility.

- Robust Dust Collection Systems To enhance workplace safety and maintain a cleaner environment, many manufacturers are integrating efficient dust collection systems into their machines.

- Energy-Efficient Designs With a growing focus on sustainability, manufacturers are designing machines that consume less power while delivering superior performance.

Market Trends

The Indian tube polishing machine market is witnessing several key trends

1. Growing Demand for Customized Solutions As industries become more specialized, the need for customized tube polishing machines that cater to specific requirements is on the rise. Manufacturers are increasingly focusing on providing bespoke solutions.

2. Rising Export Potential Indian manufacturers are not just catering to the domestic market; there is a growing trend of exporting tube polishing machines to international markets. This is driven by the competitive pricing and quality of Indian-made products.

3. Increased Adoption of Automation Companies are keen to invest in fully automated tube polishing solutions to enhance productivity, reduce labor costs, and maintain consistent product quality.

Conclusion

The tube polishing machine industry in India is poised for robust growth, driven by technological advancements and rising demand across various sectors. With key manufacturers leading the charge, the market is becoming increasingly competitive, offering a range of innovative solutions that meet the evolving needs of customers. As industries continue to prioritize quality and efficiency, the selection of the right tube polishing machine will be essential for achieving optimal results in manufacturing processes.