In the realm of industrial maintenance, the tube rust remover machine emerges as an indispensable ally. This sophisticated device, built on cutting-edge technology, revolutionizes the traditional approach to combating corrosion in tubular structures. Companies with high reliance on metal piping systems, spanning from petrochemical to water treatment industries, can dramatically enhance their operational efficiency by embracing this specialized equipment.

The crux of the machine lies in its ability to seamlessly integrate into existing workflows while providing high precision in rust removal. Unlike manual rust removal methods that require significant human effort and time, the tube rust remover machine automates the process, ensuring consistent results. It offers an experience transformation, liberating workers from strenuous tasks and redirecting focus towards more strategic maintenance activities.

One of the notable features of this machine is its innovative design, which combines mechanical and chemical processes to eradicate rust effectively. The mechanical components ensure thorough surface cleaning, while the integrated chemical treatment neutralizes rust, preventing future occurrence. This dual-action mechanism embodies a synergy that few solutions in the market can match, demonstrating expertise in tackling rust challenges.

Authoritativeness in device design is underscored by its development backed by leading engineers in corrosion technology. With extensive research and development cycles, the machine embodies years of industry insights and technological advancements. This ensures that companies investing in this equipment are not only procuring a tool but aligning with a legacy of engineering prowess.

Trustworthiness, a paramount consideration for industrial equipment, is addressed through stringent quality controls and certifications. Each machine undergoes rigorous testing phases, simulating real-world conditions, to guarantee optimal performance upon deployment. Testimonials from field operators and engineers further cement trust, citing substantial reductions in downtime and maintenance costs after integrating the machine into their operations.

tube(pipe) rust remover machine

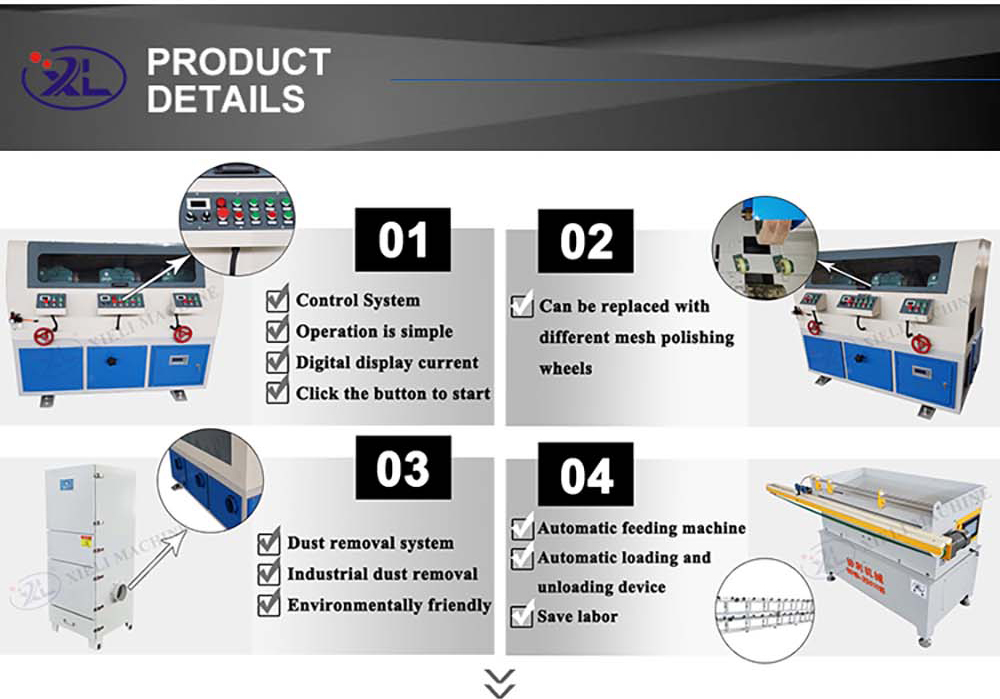

Beyond its core functionality, the machine boasts user-friendly interfaces and intuitive controls, making it accessible even for operators with minimal technical training. Digital displays provide real-time feedback, enabling precise adjustments and comprehensive monitoring throughout the rust removal process. This enhances user experience, reducing learning curves and promoting prompt adoption across varied industrial settings.

The economic benefits extend beyond reduced labor costs and machinery downtime. By ensuring pipelines and tubes remain in peak condition through efficient rust removal, this machine extends the lifespan of these assets, yielding long-term savings. Additionally, maintaining rust-free pipes enhances safety and product quality, particularly crucial in industries where contamination could have severe implications.

Sustainability, a growing concern in industrial processes, is also addressed by the machine’s eco-friendly operations. Advanced filtration and waste management systems within the device ensure minimal environmental impact, promoting responsible management practices within industrial setups.

In conclusion, the tube rust remover machine is not just a tool; it encapsulates a comprehensive solution that champions efficiency, reliability, and sustainability. Its integration into industrial processes signifies a forward-thinking approach to maintenance, reflecting a commitment to leveraging technology for superior outcomes. Companies poised to meet the demands of modern maintenance must consider this machine a crucial investment, transforming their maintenance strategies while fostering a culture of innovation and environmental stewardship.