Tube Grinding Machine Enhancing Precision in Metalworking

In the world of manufacturing and metalworking, precision and efficiency are paramount. Among the many tools and machines that have been developed to meet these demands, the tube grinding machine stands out as a crucial piece of equipment. Designed specifically for the grinding of tubes and pipes, these machines play a vital role in the production process, ensuring both the quality of the end product and the efficiency of the workflow.

Understanding Tube Grinding Machines

A tube grinding machine is a type of machinery specifically engineered for the grinding and finishing of cylindrical components, particularly tubes and pipes. These machines are utilized in various industries, including automotive, aerospace, manufacturing, and construction, where precision and surface finish are critical for performance and safety. The primary purpose of a tube grinding machine is to remove material from the surface of the tube, thereby improving dimensional accuracy and surface quality.

The operation of these machines typically involves a rotating grinding wheel that is brought into contact with the tube. As the tube is advanced through the machine, the grinding wheel removes material, resulting in a smoother and more precise surface. Advanced tube grinding machines may incorporate CNC (Computer Numerical Control) technology, allowing for intricate programming and automation of the grinding process, which significantly enhances productivity and reduces human error.

Key Features of Tube Grinding Machines

1. Versatility Tube grinding machines come in various configurations to accommodate different tube materials, sizes, and shapes. Whether dealing with stainless steel, aluminum, or other metals, these machines can adapt to the specific requirements of the material being processed.

2. Automation Modern tube grinding machines often incorporate automated features, such as CNC technology, which allows for more consistent and precise grinding operations. Automation reduces the reliance on manual labor and increases output rates, making it a favorable option for high-volume production environments.

3. Precision One of the most significant advantages of using a tube grinding machine is its ability to produce highly precise components. The grinding process not only improves surface finish but also ensures that the dimensions of the tubes meet the required tolerances.

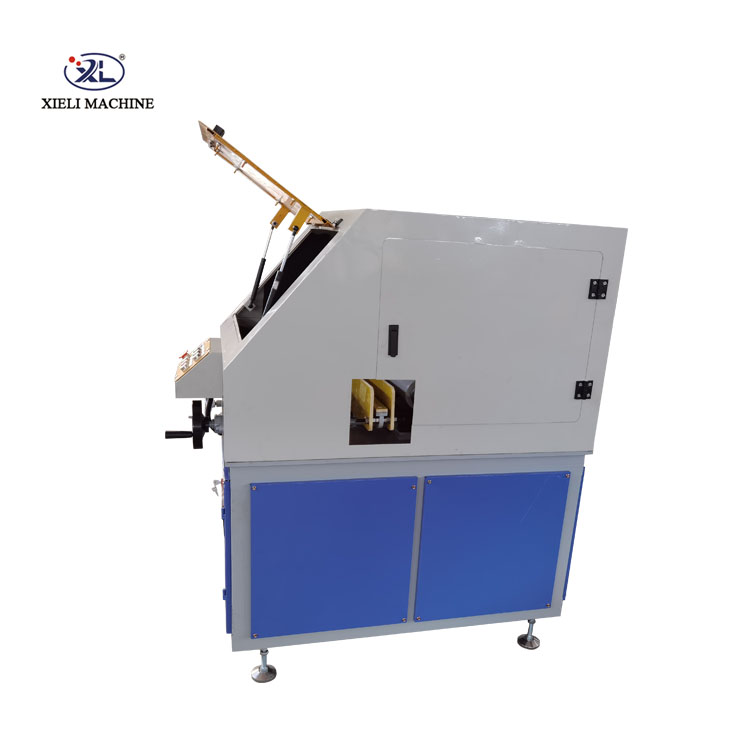

tube grinding machine product

4. Efficiency By utilizing advanced grinding techniques, tube grinding machines can operate at high speeds while maintaining accuracy, ultimately speeding up the production cycle. The efficient removal of material leads to reduced waste and optimized manufacturing processes.

5. Surface Finish Achieving a superior surface finish is critical for many applications. Tube grinding machines are capable of producing surfaces that are not only aesthetically pleasing but also functional, reducing friction and wear in components that will be subjected to high stress.

Applications of Tube Grinding Machines

The applications of tube grinding machines are extensive and varied. In the automotive industry, these machines are often used to prepare exhaust pipes, fuel lines, and other critical components. In aerospace, the precision grinding of tubes is essential for ensuring the integrity and safety of aircraft structures and systems. Furthermore, industries involving plumbing, HVAC, and structural steelwork rely on tube grinding machines to ensure that their products meet stringent quality standards.

Challenges and Future Trends

Despite their advantages, the operation of tube grinding machines is not without challenges. Factors such as wear and tear on grinding wheels, the need for regular maintenance, and the management of waste can pose difficulties for manufacturers. To address these issues, continuous improvements in machine design and materials are being explored. Innovations such as advanced monitoring systems, improved grinding materials, and eco-friendly practices are shaping the future of tube grinding technology.

As manufacturing processes evolve, the demand for more efficient and precise tube grinding machines will continue to grow. The integration of advanced technologies like AI and machine learning into the operational framework of tube grinding machines promises to enhance their capabilities even further, allowing for real-time adjustments and predictive maintenance, which will ultimately lead to improved productivity and sustainability in metalworking.

Conclusion

In conclusion, tube grinding machines represent the backbone of precision in metalworking, facilitating the production of high-quality tubes and pipes essential for various industries. As technology advances, these machines are set to become even more efficient and versatile, helping manufacturers meet the increasing demands for quality and precision in their products. Understanding the features, benefits, and future trends surrounding tube grinding machines is crucial for any business looking to enhance its manufacturing capabilities and remain competitive in the modern marketplace.