The Rise of GP Centerless Grinder Exporters Transforming Manufacturing Landscapes

In the rapidly evolving landscape of modern manufacturing, precision machinery plays a pivotal role in enhancing productivity and quality. Among such advanced machinery, centerless grinders have emerged as indispensable tools for achieving optimal performance in an array of industries, ranging from automotive to aerospace. Notably, GP Centerless Grinder exporters have begun to carve a niche in this dynamic market, helping to redefine operational efficiencies across global manufacturing sectors.

What is a Centerless Grinder?

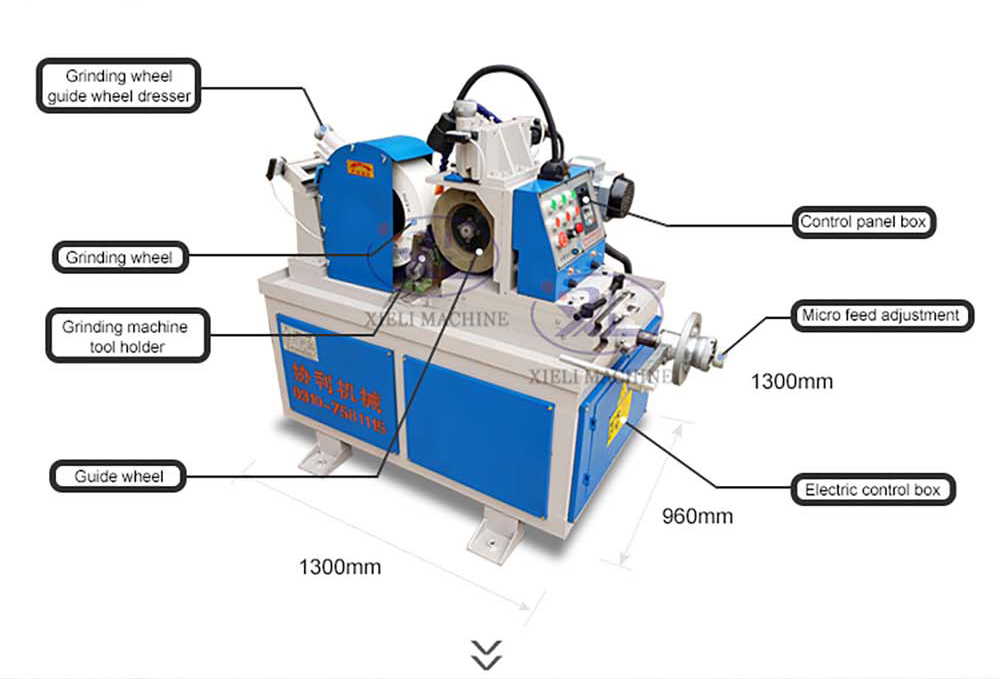

Before delving into the impact of GP Centerless Grinder exporters, it is essential to understand what a centerless grinder is. Unlike traditional grinders that require support between centers, centerless grinders use a unique mechanism that allows the workpiece to be held in place without any central fixture. The process involves the use of two wheels a grinding wheel and a regulating wheel. The workpiece is placed between these wheels, allowing it to be precisely ground to the desired dimensions.

The benefits of centerless grinding are numerous. It allows for high production rates, reduces the risk of workpiece damage, and enhances the overall accuracy of machining processes. Additionally, the continuous process of centerless grinding significantly minimizes setup times and optimizes resource utilization, making it an attractive option for manufacturers worldwide.

The Role of GP Centerless Grinder Exporters

GP Centerless Grinder exporters have taken the initiative to provide advanced centerless grinding solutions to manufacturers across various regions. With the globalization of supply chains, the demand for high-quality machinery has surged. Exporters like GP have recognized this opportunity and have become key players in the international market by offering a wide range of machines equipped with cutting-edge technology.

One of the standout features of GP's offerings is their commitment to sustainability and efficiency. Modern centerless grinders exported by GP are designed not only for performance but also for environmental considerations. With energy-efficient motors and reduced waste generation, these machines are paving the way for eco-friendly manufacturing practices.

Enhancing Competitive Advantage

gp centerless grinder exporter

The introduction of GP Centerless Grinders into international markets has had a profound effect on the competitive landscape. Manufacturing companies that integrate these advanced grinders into their operations find themselves working at a significant advantage. The precision offered by GP machines enables manufacturers to produce components that meet the tight tolerances required in today’s market.

Moreover, the reliability and durability of GP centerless grinders mean that companies can expect lower downtime and maintenance costs. This ensures continuous production processes, allowing businesses to meet the growing demands of customers without interruption. As a result, manufacturers can enhance their profitability while maintaining high standards of product quality.

Global Partnerships and Innovation

The strength of GP Centerless Grinder exporters lies not only in their machinery but also in their ability to build strong relationships with global partners. By working closely with manufacturers in diverse industries, GP can stay informed about emerging needs and challenges, allowing them to innovate continuously.

Their focus on customer support and service ensures that manufacturers are equipped to get the most out of their equipment. This partnership approach fosters a collaborative ecosystem where feedback from users contributes directly to the ongoing improvement and evolution of the machines offered.

Conclusion

The emergence of GP Centerless Grinder exporters marks a significant chapter in the story of global manufacturing. By providing highly efficient, reliable, and environmentally friendly grinding solutions, they have successfully positioned themselves at the forefront of the industry. As manufacturers increasingly seek ways to enhance productivity and competitiveness, the demand for advanced centerless grinding technology is expected to continue its upward trajectory.

In this ever-changing landscape, GP's commitment to innovation, quality, and sustainable practices will play a crucial role in shaping the future of manufacturing. Enhanced operational efficiencies and stronger global partnerships will undeniably lead to a more prosperous and resilient industrial ecosystem. Thus, the influence of GP Centerless Grinder exporters is set not only to impact machinery supply but also to transform the very way industries operate worldwide.