The Importance of Centerless Cylindrical Grinding Machines in Modern Manufacturing

In the vast realm of manufacturing processes, precision and efficiency are paramount. Among the methods employed to achieve these goals, centerless cylindrical grinding has emerged as a crucial technique, particularly for producing high-quality cylindrical parts. This article will explore the significance of centerless cylindrical grinding machines, their operation, and their advantages in modern manufacturing.

What is Centerless Cylindrical Grinding?

Centerless cylindrical grinding is a machining process that involves grinding the exterior surface of cylindrical workpieces. Unlike traditional cylindrical grinding, where the part is held between centers, centerless grinding does not require the piece to be fixed in a precise location. Instead, it uses a system of rollers to support the workpiece, which allows for continuous rotation and movement. This technique is particularly advantageous for mass production where precision and speed are critical.

How Centerless Grinding Machines Work

Centerless grinding machines consist of two main grinding wheels—the grinding wheel and the regulating wheel. The grinding wheel is responsible for removing material from the workpiece, while the regulating wheel controls the speed and positioning of the object being worked on. Together, these wheels efficiently grind the workpiece as it passes through the machine.

The setup generally requires the workpiece to be positioned between the two wheels, supported by a work rest. As the grinding wheel rotates, it removes material from the cylindrical surface. The regulating wheel, on the other hand, rotates at a different speed, pushing the workpiece through the grinding zone. The ability to adjust the angles and speeds of these wheels allows for precise control over the grinding process, enabling manufacturers to achieve tight tolerances and exceptional surface finishes.

Advantages of Centerless Cylindrical Grinding Machines

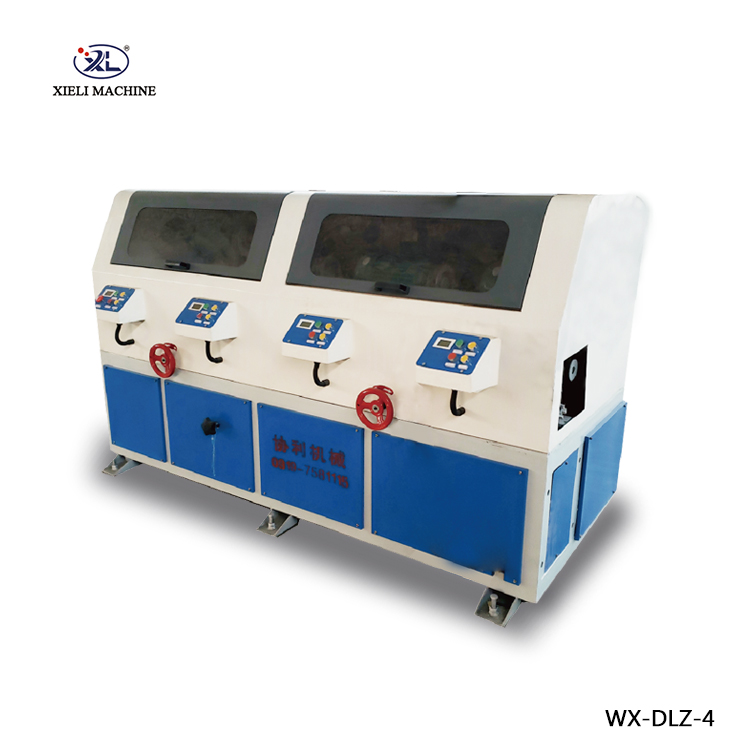

famous centerless cylindrical grinding machine

1. High Efficiency One of the most significant benefits of centerless grinding machines is their ability to work quickly and efficiently. The continuous cycle of grinding allows for the production of large volumes of parts in a shorter time frame compared to other grinding methods.

2. Cost-Effectiveness The streamlined process of centerless grinding can lead to reduced operational costs. By minimizing the need for fixturing and reducing the cycle time, manufacturers can save both time and money.

3. Precision and Tolerance Centerless grinding machines are capable of achieving tight tolerances, making them ideal for applications that require high precision, such as in the automotive and aerospace industries. The ability to maintain consistent measurements is essential for the durability and functionality of the manufactured parts.

4. Versatility These machines can accommodate a wide range of materials and sizes. From small components to larger cylindrical pieces, centerless grinding can adapt to different manufacturing needs, making it a versatile choice for various industries.

5. Minimal Setup Time Changing from one workpiece to another on a centerless grinder typically requires less time than reconfiguring other types of grinding machines, making it easier to switch between different product lines.

Conclusion

Centerless cylindrical grinding machines are essential tools in modern manufacturing, providing efficiency, precision, and versatility. Their ability to produce high volumes of parts with exceptional quality has made them indispensable, particularly in industries where performance and durability are critical. As technology continues to advance, the capabilities of centerless grinding machines are likely to evolve further, solidifying their place at the forefront of manufacturing processes. Understanding the importance of these machines can help manufacturers optimize their operations and meet the ever-growing demands for high-quality components in a competitive marketplace.