Creating a DIY centerless grinder can be an immensely rewarding project, offering both a deep dive into mechanical engineering and an opportunity to produce essential parts for a variety of applications. In exploring this topic, it is crucial to focus on practical experiences, technical proficiency, authoritative insights, and ensuring the trustworthiness of the information provided.

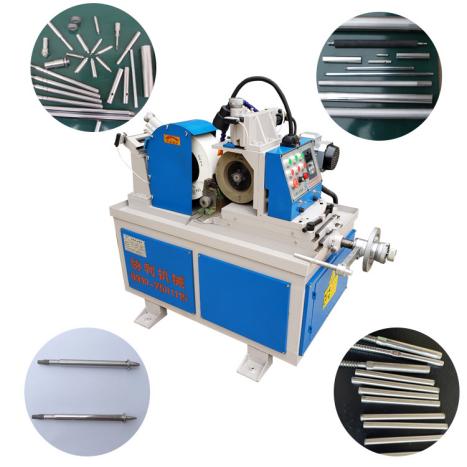

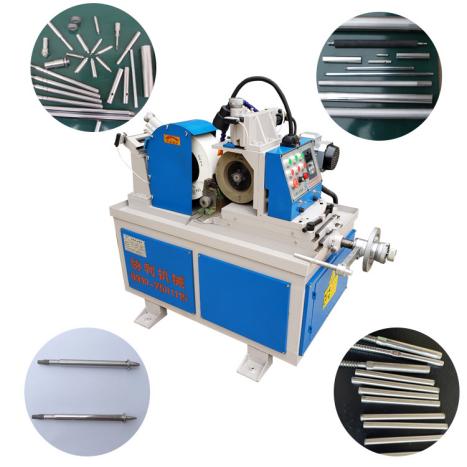

Enthusiasts entering the world of DIY machinery often begin with a curiosity about precision tools, and the centerless grinder stands out as an intriguing challenge. A traditional centerless grinder typically comprises three main components the grinding wheel, the regulating wheel, and the work support blade. The absence of a spindle in a centerless grinder enhances its versatility for handling parts of varying sizes with exceptional accuracy.

The journey begins with understanding the core functioning of commercial centerless grinders. These machines skillfully grip parts and revolve them at high speeds, removing material gradually with unparalleled precision. For DIY enthusiasts, replicating this function starts with selecting appropriate materials for each component. The grinding wheel often requires a high-quality abrasive material like diamond or tungsten carbide, which ensures endurance against wear and tear over extended periods of use.

Expertise in mechanical engineering becomes invaluable as one begins designing the blueprint. Dimensions and materials are not just specs; they are the foundation of an efficient grinding machine. The regulating wheel, often crafted from rubber or composites, demands precise calibration to keep the workpiece from deflecting, which could otherwise jeopardize the entire machining process. Attention to torque and rotational speeds, adjusted through the regulating wheel, illustrates the delicate balance between artisanal craftsmanship and scientific principles.

One of the considerable advantages of a DIY centerless grinder is customization. Unlike industrial equipment, a DIY grinder can be tailored to specific projects or materials. This flexibility allows for enhancements, such as integrating variable speed settings or adapting the tool to work efficiently with both metallic and non-metallic materials. Trustworthy advice from industry veterans suggests starting with simpler models that facilitate the learning curve before venturing into more intricate assemblies.

diy centerless grinder

Safety during the construction and operation of a centerless grinder cannot be overstated. Utilizing heavy-duty gloves, protective eyewear, and understanding the mechanical stresses within the machine are essential practices. Confidence in operating the grinder comes from thorough testing phases and iterative improvements, allowing the user to gain a hands-on experience that is both educational and rewarding.

Although primarily a solo endeavor, valuable insights are often gleaned from collaborating within dedicated online communities. These forums and groups provide a platform for sharing challenges, triumphs, and technical breakthroughs. Through these conversations, credibility is established as techniques and materials are vetted through communal knowledge sharing.

Moreover, the environmental implications of crafting a DIY centerless grinder align with sustainable practices. By repurposing discarded components or sourcing ethically produced materials, builders further contribute to viability and set standards for eco-friendly designs in personal engineering projects.

The authority in constructing a DIY centerless grinder does not merely stem from technical expertise but also from the novelty of combining contemporary advancements with timeless mechanical principles. Indeed, the gratification of watching mere components become a sophisticated tool adds a profound personal achievement layer.

Building a centerless grinder is a reflection of not just technical prowess but also the metamorphosis of basic materials into a tool that exemplifies precision and innovation. As more hobbyists embark on such projects, this embodiment of human ingenuity continues to inspire future innovations in the pursuit of mechanical mastery.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.