Exploring the Benefits of Discount Square Pipe Polishing Machines

In today’s competitive manufacturing landscape, enhancing product quality while managing costs is critical for success. One of the essential aspects of this equation is the finishing process, particularly for items such as square pipes. An effective way to streamline and perfect the polishing of square pipes is through using specialized polishing machines. With technology advancing rapidly, discount square pipe polishing machines have emerged as a popular choice among manufacturers looking to optimize their operations without breaking the bank.

Understanding Square Pipe Polishing Machines

Square pipe polishing machines are designed to deliver fine finishes to square and rectangular tubes. They effectively remove surface imperfections, oxidized layers, and any unwanted material that can affect the aesthetic and functional characteristics of the pipes. These machines can enhance the metal's reflective qualities, making them ideal for industries where appearance plays a crucial role, such as automotive, architecture, and furniture.

Why Choose Discount Options?

While high-end polishing machines come with advanced features and guarantees of performance, the cost can be prohibitive for many businesses, particularly smaller manufacturers or those just starting out. Discount square pipe polishing machines provide a cost-effective alternative. Clients can find quality polishing solutions that meet their production needs without the substantial investment that top-tier equipment demands.

Several manufacturers offer discounted machines without compromising on quality. They have optimized production processes and are willing to pass those savings onto customers. Purchasing a discount machine doesn't mean settling for less; many of these machines are equipped with state-of-the-art technology that ensures efficient operation, durability, and minimal maintenance requirements.

Advantages of Polishing Machines

1. Consistency and Quality Manual polishing can lead to variability in finish quality. Using a machine ensures that each pipe receives a consistent polish, improving overall product standardization. Factory settings can often be adjusted to maintain uniform results across all pieces.

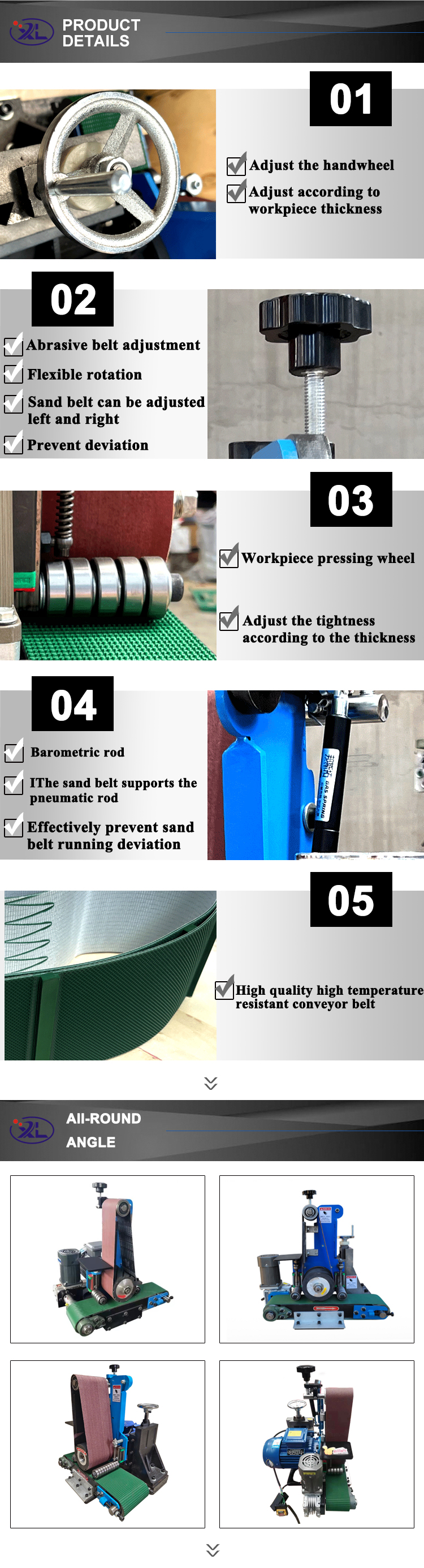

discount square pipe polishing machine

2. Increased Productivity Polishing by hand is labor-intensive and time-consuming. Machines can process dozens of pipes in the same time it would take a worker to polish just a few. This enhancement in throughput allows manufacturers to meet larger orders and reduce lead times.

3. Employee Safety Polishing is not only tedious; it can also pose safety risks if done manually for prolonged periods. Machines minimize worker exposure to hazardous materials, vibrations, and the repetitive stress associated with hand work, creating a safer workplace environment.

4. Cost Efficiency While discount machines might seem like a budget-conscious choice, they can also reduce the overall cost of production. Increased productivity means lower labor costs and faster delivery, directly impacting a company’s bottom line favorably.

5. Versatility Many modern square pipe polishing machines come with adjustable settings, allowing them to accommodate various sizes and materials. This versatility makes them an investment that can adapt to changing production needs over time.

Choosing the Right Machine

When seeking a discount square pipe polishing machine, it's essential to evaluate suppliers based on several criteria. Consider the machine’s specifications, warranty, and after-sales service. Reading reviews and testimonials from other customers can provide insight into the reliability and performance of the equipment.

Finally, determine your production requirements and budget to make an informed decision. Purchasing a machine that is too advanced for your needs may be a waste of resources, while opting for a machine that is too basic may hinder your productivity.

Conclusion

In conclusion, discount square pipe polishing machines represent an excellent opportunity for manufacturers to enhance their production quality without incurring exorbitant costs. By investing in such machines, businesses can achieve improved consistency, faster processing times, and enhanced worker safety. As manufacturing demands grow and evolve, embracing technology through reliable solutions like polishing machines will be crucial for staying competitive in the marketplace.