Overview of Desktop Polishing Machine Factories

In today's fast-paced manufacturing environment, precision and efficiency are paramount. One of the critical components in achieving high-quality finishes on various products is the use of polishing machines. Among the various types of polishing machines available in the market, desktop polishing machines have gained significant traction due to their compact design, versatility, and ability to deliver excellent results in small-scale operations. This article delves into desktop polishing machine factories, exploring their significance, production processes, and contributions to various industries.

The Significance of Desktop Polishing Machines

Desktop polishing machines are essential for numerous applications across different sectors, including jewelry making, electronics, and manufacturing of consumer goods. These machines are designed to provide a high-quality polish on a range of materials, such as metals, plastics, glass, and ceramics. Their ease of use and compact size make them ideal for small workshops and home-based operations, allowing artisans and small business owners to achieve professional-grade finishes without the need for large, industrial machines.

The demand for desktop polishing machines has surged in recent years, driven by the growth of small and medium-sized enterprises (SMEs) and an increasing emphasis on customization in product design. This rise in demand has led to the establishment of specialized factories dedicated to the production of these machines.

Production Processes in Desktop Polishing Machine Factories

Desktop polishing machine factories utilize advanced manufacturing techniques to produce high-quality machines that meet the diverse needs of their customers. The manufacturing process typically involves several stages, including design, material selection, fabrication, assembly, and quality control.

1. Design and Prototyping Factories begin by employing skilled engineers and designers to create blueprints for the machines. These designs are often computer-aided, allowing for precision and efficiency. Prototypes are developed to test the functionality and ergonomics of the machines, ensuring they meet industry standards.

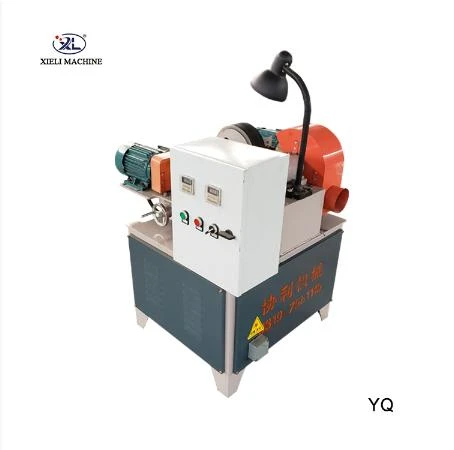

desktop polishing machine factories

2. Material Selection The choice of materials is crucial for the longevity and performance of polishing machines. Factories often use durable materials such as stainless steel and high-grade plastics capable of withstanding wear and tear. The selection process considers factors like weight, strength, and corrosion resistance.

3. Fabrication Once the design is finalized and materials chosen, factories move on to the fabrication stage. This involves cutting, machining, and shaping the materials into the required components. Modern factories employ CNC (Computer Numerical Control) technology to ensure precision in manufacturing, resulting in higher quality and consistency.

4. Assembly After fabricating the individual parts, the components are assembled into complete machines. This process involves integrating various elements, including motors, control panels, and polishing wheels. Skilled technicians supervise the assembly to ensure that each machine functions correctly.

5. Quality Control Quality assurance is a vital step in the production process. Factories implement rigorous testing protocols to evaluate the performance and safety of the machines. This includes testing for durability, operational efficiency, and adherence to safety standards. Only machines that pass these tests are approved for sale.

The Global Market and Future Prospects

The market for desktop polishing machines is set to grow, fueled by advances in technology and increased demand for high-quality finishes in various industries. Factories are continually innovating, integrating features like automation and smart technology, which allow operators to achieve better consistency and efficiency.

In summary, desktop polishing machine factories play a crucial role in the manufacturing landscape. By producing high-quality, efficient, and user-friendly machines, these factories support a variety of industries and contribute to the proliferation of small-scale businesses. As technology continues to evolve, we can expect these factories to adapt and innovate further, ensuring that the polishing solutions of tomorrow meet the changing needs of the market.