Custom Centerless Grinder Market Trends and Opportunities

The industrial landscape has evolved considerably over the years, and manufacturing processes are no exception. One of the key technologies that have seen significant advancements is centerless grinding. Unlike traditional grinding machines, centerless grinders allow for continuous workpiece production without the need for steady rest setups, making them essential in various industries such as automotive, aerospace, and precision engineering.

Understanding Centerless Grinding

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece. The key feature of this process is that the workpiece is not held or fixed between centers; instead, it is supported by the grinding wheel and a regulating wheel. This method offers several advantages, including enhanced production rates, improved surface finish, and the ability to handle various workpiece sizes and shapes.

The Rise of Custom Centerless Grinders

As manufacturing becomes more competitive, companies seek ways to improve efficiency and flexibility in their production processes. Custom centerless grinders have emerged as a solution to meet specific grinding requirements. These machines are tailored to the unique needs of manufacturers, taking into account the material type, part geometry, and desired tolerances.

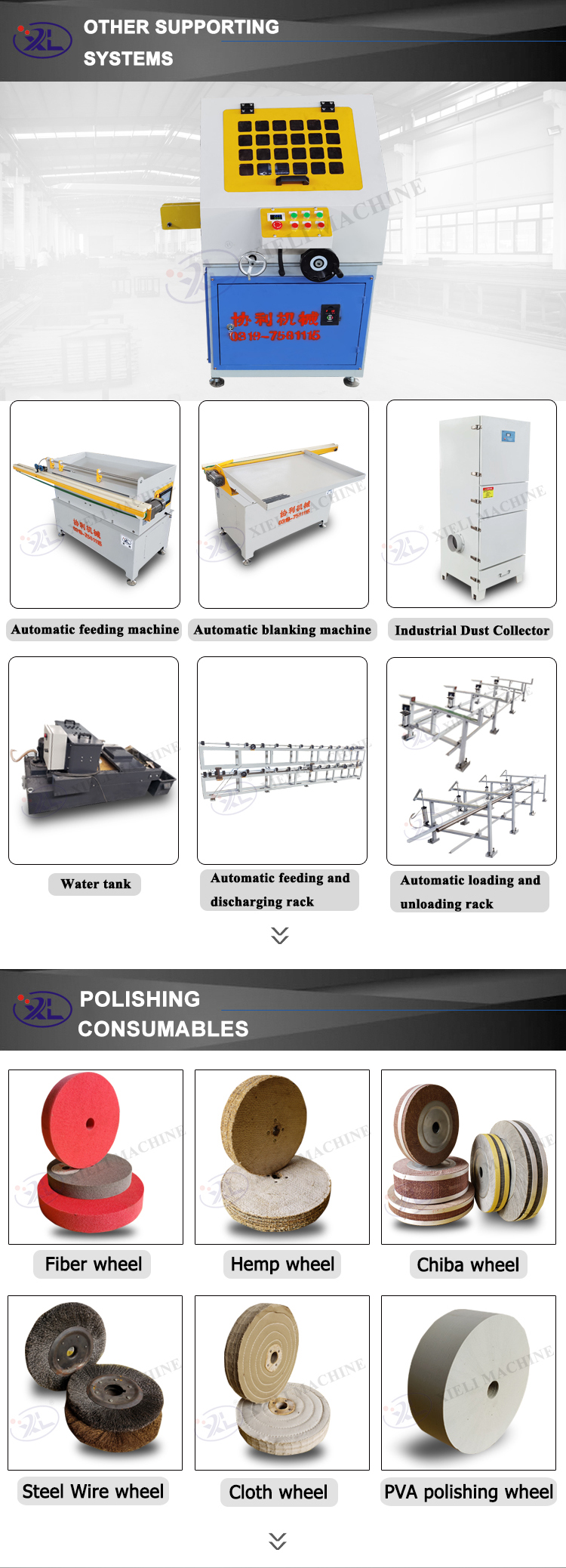

The demand for custom centerless grinders has spurred innovation in machine design, automation, and integration with smart technologies. Manufacturers can now access machines equipped with advanced features such as CNC control, automatic feeding systems, and real-time monitoring capabilities. This not only enhances productivity but also reduces lead times and waste, aligning with the industry's push towards sustainability.

Market Trends

custom centerless grinder market

Several trends are shaping the custom centerless grinder market. First, the increasing focus on precision engineering is driving demand for machines that can achieve tight tolerances and high-quality finishes. Industries such as defense and medical device manufacturing require components that meet stringent specifications, making custom solutions essential.

Second, automation is becoming increasingly important. With the advent of Industry 4.0, manufacturers are looking for equipment that can integrate seamlessly with existing systems. Custom centerless grinders equipped with IoT capabilities allow for remote monitoring and data collection, providing insights into machine performance and maintenance needs. This trend not only boosts productivity but also enhances decision-making based on real-time data.

Third, there is a growing emphasis on sustainability and the reduction of carbon footprints. Custom centerless grinders are being designed with energy efficiency in mind, utilizing new technologies that minimize waste and optimize resource use. Manufacturers are also exploring the use of eco-friendly materials and processes, further driving innovation in the market.

Opportunities in Emerging Markets

Emerging markets represent a significant growth opportunity for the custom centerless grinder market. Countries in Southeast Asia, Eastern Europe, and South America are witnessing rapid industrialization, which in turn increases the demand for advanced manufacturing technologies. As these regions develop, the need for high-precision grinding solutions will grow, prompting local companies to seek out custom machines tailored to their specific requirements.

Moreover, as global supply chains become more complex, the emphasis on locally sourced components is likely to rise. This shift can lead to a greater emphasis on companies that can provide custom solutions swiftly and affordably, thus making a mark in the local markets.

Conclusion

The custom centerless grinder market is poised for significant growth, driven by trends in precision engineering, automation, and sustainability. As manufacturers across various sectors continue to prioritize efficiency and customization, the demand for tailored grinding solutions is expected to rise. By adapting to changing market dynamics and embracing technological advancements, manufacturers of custom centerless grinders can create innovative solutions that meet the evolving needs of their clients while reinforcing their competitive edge in the manufacturing landscape. With the right strategies, the future of the custom centerless grinder market looks promising, filled with opportunities for growth and innovation.