Enhancing production efficiencies and ensuring the highest levels of precision are paramount in any manufacturing process. CNC centerless grinder machines have emerged as indispensable tools in achieving these objectives, thanks to their advanced technology and high precision capabilities. Here, we delve into the realm of CNC centerless grinder machines, offering insights from seasoned experts and illuminating the landscape with authentic experiences.

In the world of machining, precision is king. CNC centerless grinders, known for their ability to remove material with meticulous accuracy, have revolutionized how parts are manufactured. Unlike traditional grinders, CNC centerless machines operate without a spindle or fixture to secure the workpiece. Instead, they employ a cutting process where the workpiece is supported between a grinding wheel and a regulating wheel. This method ensures higher repeatability and superior surface finishes, making it a preferred choice in industries like aerospace, automotive, and medical device manufacturing.

Industry experts emphasize the seamless integration and adaptability of CNC technology within centerless grinding. The programmable nature of CNC systems allows operators to execute complex grinding profiles with unparalleled precision. As a result, manufacturers can produce parts with tighter tolerances and consistent quality. Furthermore, the automation embedded in CNC systems drastically reduces manual intervention, decreasing the chance of human error and increasing overall operational efficiency.

Through firsthand experience, manufacturers have witnessed significant improvements in productivity with CNC centerless grinders. One such example is a leading automotive components manufacturer that transitioned from conventional grinding methods. By adopting CNC centerless grinders, they reduced cycle times by 30% and achieved a 40% reduction in scrap rates. This transformation not only curtailed production costs but also met the escalating demand for high-quality components.

cnc centerless grinder machine quotes

Choosing the right CNC centerless grinder demands expertise, as subtle differences in machine design and functionality can impact performance significantly. Key features to consider include the type of wheel system, machine rigidity, and the capabilities of the CNC software. Machines with superior rigidity improve cutting capabilities while minimizing vibrations, which is critical for maintaining accuracy over prolonged use.

Authoritative knowledge from industry veterans suggests that selecting a machine with a robust CNC control system can enhance the machine's flexibility and efficiency. The software should support easy programming and swift adaptation to new production requirements, which is particularly beneficial for industries where machine tasks vary frequently.

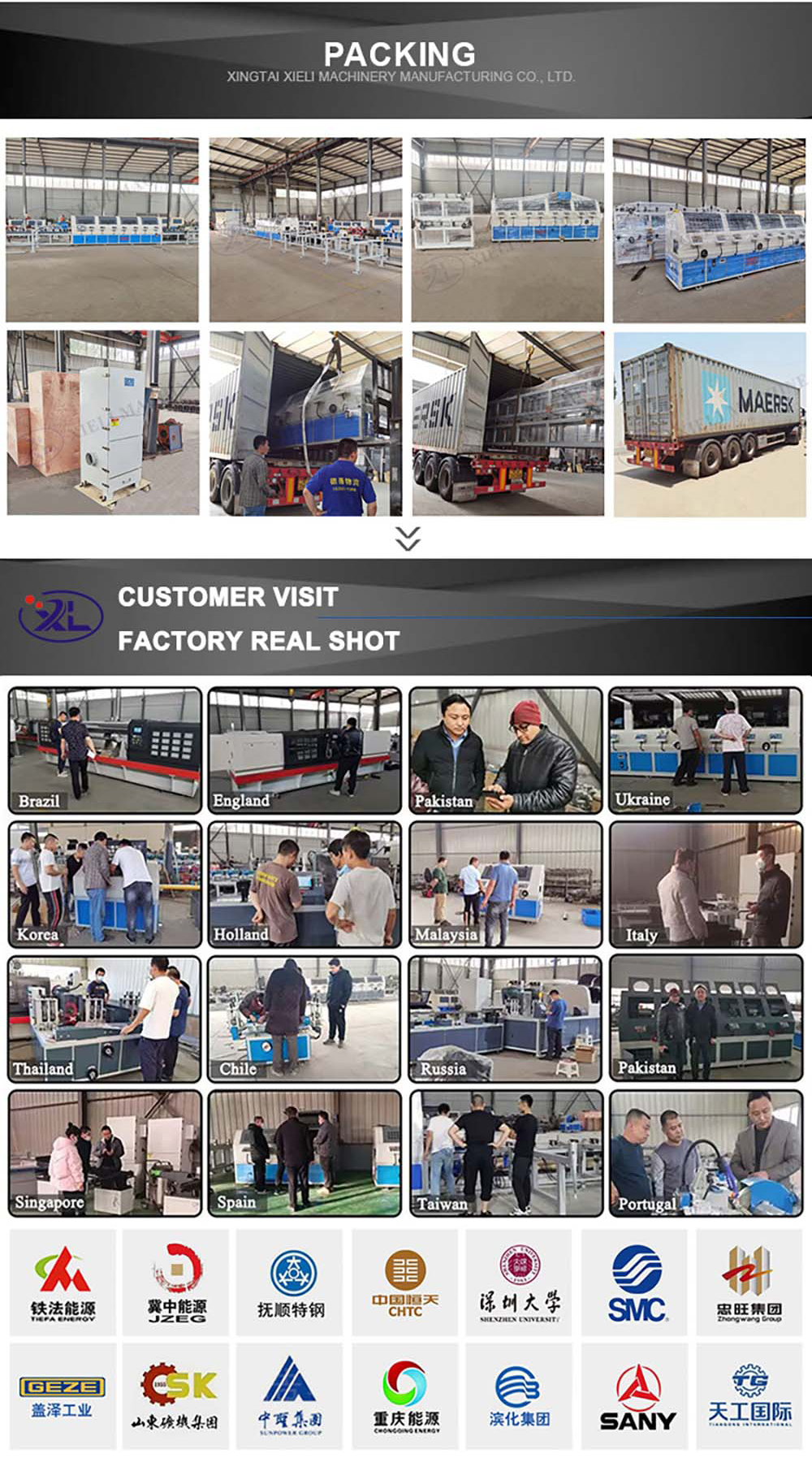

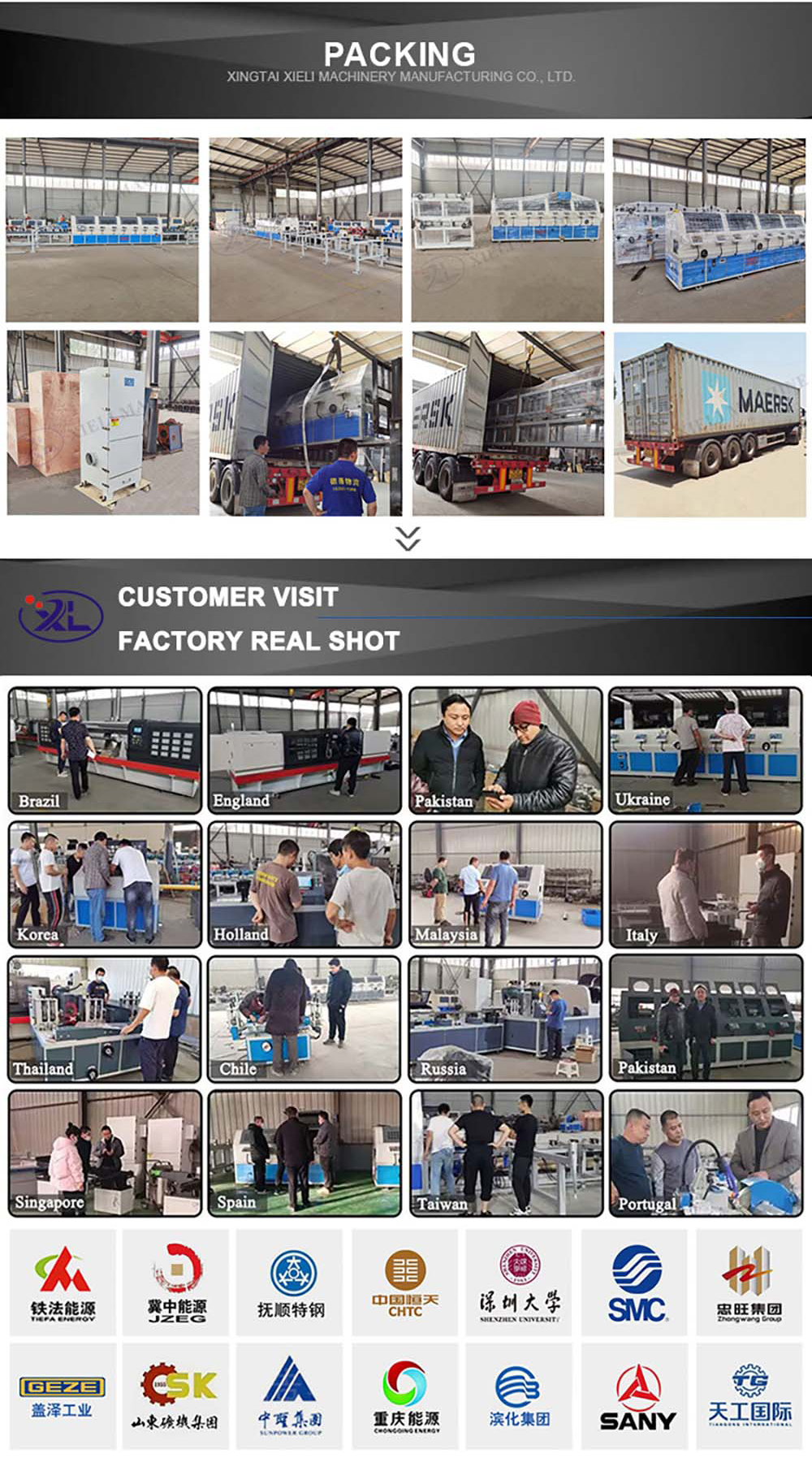

Trustworthiness in CNC centerless grinder machines stems from the reliability and durability of the equipment. Reputable manufacturers invest in high-quality materials and components, which translates into machines that withstand the rigors of continuous production runs. Additionally, comprehensive warranty packages and responsive customer service can be strong indicators of a manufacturer's commitment to product quality and customer satisfaction.

In conclusion, the CNC centerless grinder machine is a quintessential asset for manufacturers striving for zero defects and enhanced productivity. With expert insights, a seasoned understanding of machine functionality, and an unwavering commitment to quality, businesses can leverage CNC centerless grinding technology to gain a competitive edge in precision manufacturing. These machines, with their blend of advanced technology and proven reliability, continue to pave the way for innovations in various sectors, ensuring that manufacturing processes remain at the forefront of efficiency and quality.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.