Understanding the Importance of Cinco 2015 Centerless Grinder Parts

Centerless grinding is an essential manufacturing process used for finishing and shaping metal and other materials. One of the key players in this domain is the Cinco 2015 centerless grinder, a machine that has gained recognition for its precision and efficiency. However, like any specialized machinery, the performance of the Cinco 2015 is heavily reliant on its parts and components. In this article, we will explore the significance of quality parts for the Cinco 2015 centerless grinder, their roles, and how they contribute to the overall functionality and longevity of the machine.

The Functionality of Centerless Grinders

Centerless grinders operate on the principle of not having a fixed position or “center,” which distinguishes them from traditional grinding machines. This method allows for the grinding of cylindrical parts without the need for a complex setup, leading to increased productivity. The Cinco 2015 model is specifically designed for high throughput and consistent output, making it ideal for various industries such as automotive, aerospace, and tooling.

The Role of Quality Parts

Each component within the Cinco 2015 centerless grinder plays a critical role. Key parts include the grinding wheel, regulating wheel, work rest, and bearings. Each of these components contributes to the precision and efficiency of the grinding process.

1. Grinding Wheel The grinding wheel is perhaps the most crucial part of the machine. High-quality grinding wheels provide better material removal rates and improved surface finishes. Selecting the right grit and bond type is essential for optimizing performance and ensuring the longevity of both the wheel and the machine.

2. Regulating Wheel This wheel controls the speed of the workpiece as it passes through the grinding section. Proper alignment and condition of the regulating wheel are vital for achieving accurate dimensions and desired surface finishes.

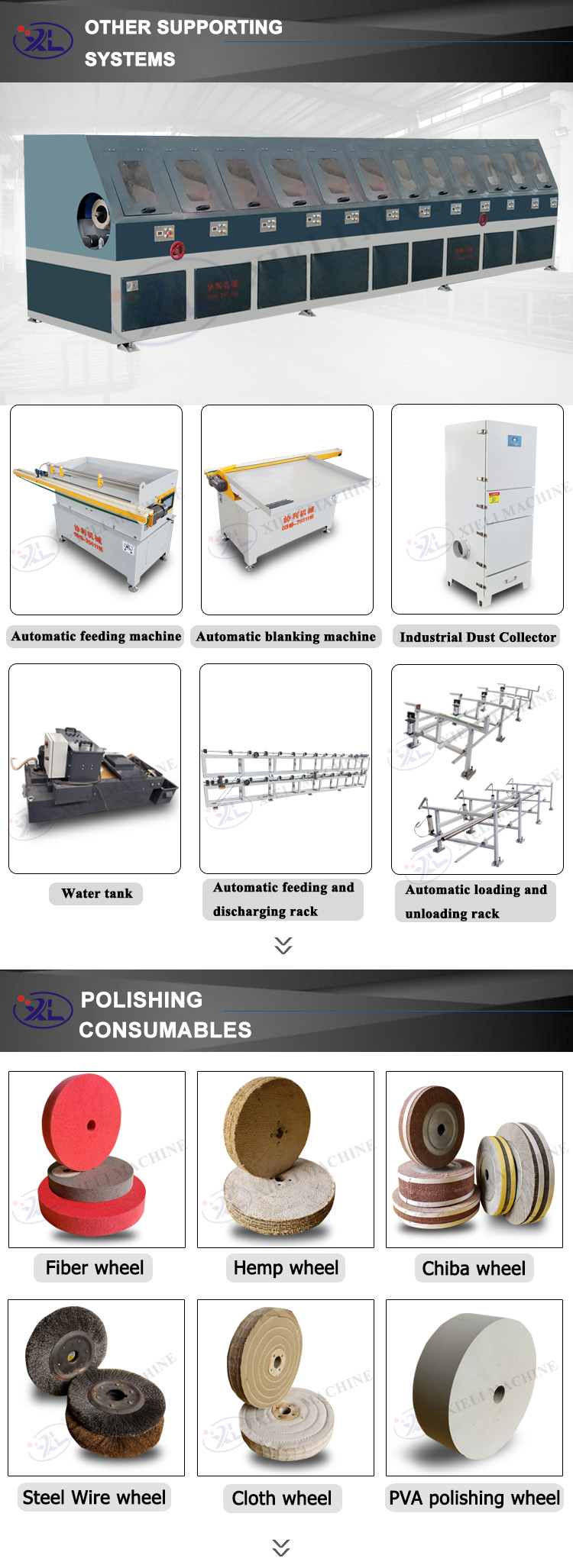

cinco 15 centerless grinder parts products

3. Work Rest The work rest supports the part being ground, ensuring it remains stable during the grinding process. A properly adjusted work rest is essential for achieving uniformity and avoiding wear on other parts.

4. Bearings Bearings ensure smooth operation with minimal friction. High-quality bearings reduce heat generation and wear, contributing to the machine's overall operational efficiency.

Maintenance of Centerless Grinder Parts

Regular maintenance of the components of the Cinco 2015 centerless grinder is crucial for maximizing performance and extending the life of the machine. This includes routine inspections and timely replacements of worn parts. Ignoring maintenance can lead to discrepancies in grinding precision and could result in costly downtime.

Choosing the Right Parts

When it comes to sourcing parts for the Cinco 2015 centerless grinder, manufacturers should prioritize quality over cost. Utilizing OEM (Original Equipment Manufacturer) parts is typically recommended, as these components are specifically engineered to meet the performance standards set by the machine's designers. While aftermarket options may be less expensive, they often do not offer the same level of reliability or longevity.

Conclusion

In summary, the Cinco 2015 centerless grinder is a sophisticated piece of machinery that thrives on the quality and precision of its parts. Understanding the key components and their respective roles can significantly impact the machine's performance and efficiency. To ensure optimal operation, it is vital to invest in high-quality parts and carry out regular maintenance. By doing so, manufacturers can enhance productivity, reduce downtime, and ultimately drive better results in their grinding operations. The importance of quality parts in the Cinco 2015 centerless grinder cannot be overstated; they are, after all, the backbone of a successful grinding process.