The Cincinnati Twin Grip Centerless Grinder stands out in the machine world as a pinnacle of precision engineering. For those who rely on these machines for their production lines, having expert service on speed dial is crucial. When breakdowns occur, they can cause costly delays and compromise the quality of your product. Here's why expert service for the Cincinnati Twin Grip Centerless Grinder is imperative and what you should look for in a servicing company.

To understand the importance of regular maintenance and service, one has to acknowledge the unique design of the Cincinnati Twin Grip. Its architecture allows for extreme precision and control, making it capable of delivering exceptional finish and consistency. However, this same complexity requires specialized knowledge for upkeep and repair. Not every machine technician has the training or experience to handle these intricacies, and that's where the value of experienced professionals comes into play.

A qualified service technician brings a wealth of expertise to the table. With years of hands-on experience, they not only repair but also anticipate and prevent potential issues before they become significant disruptions. Expertise in the Cincinnati Twin Grip's specific mechanical and hydraulic systems is non-negotiable, as these areas demand precision tuning. Ensuring that parts like spindles, control systems, and hydraulic units are regularly serviced and calibrated will maintain the grinder's performance at optimal levels.

Authoritativeness is another cornerstone when choosing a service provider. A reputable service company will have a demonstrated track record of handling the Cincinnati Twin Grip Centerless Grinder and should come recommended by other industry leaders. This authority isn't just granted; it's earned through years of consistent, high-quality service delivery. Leveraging genuine customer testimonials and case studies, a provider can showcase their ability to keep these complex machines running smoothly and efficiently.

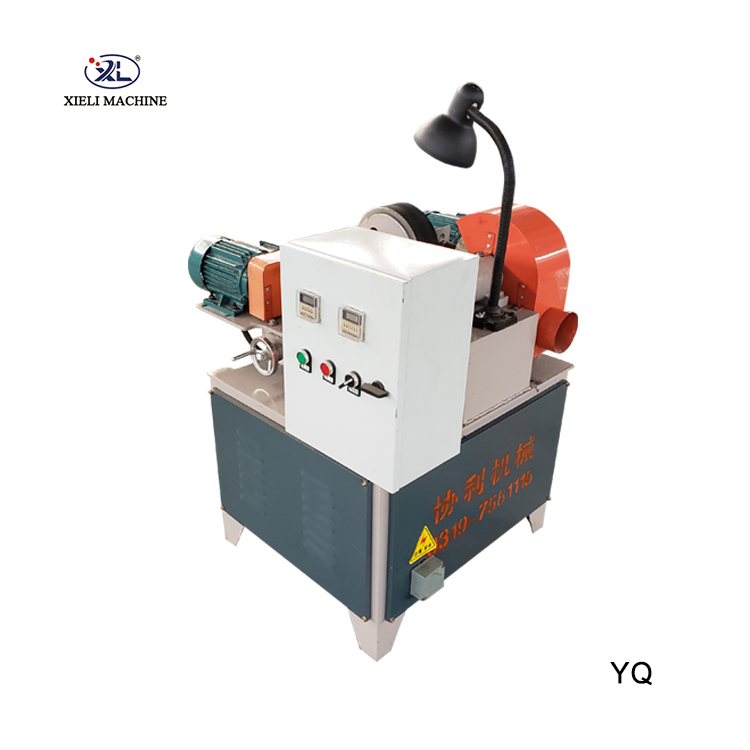

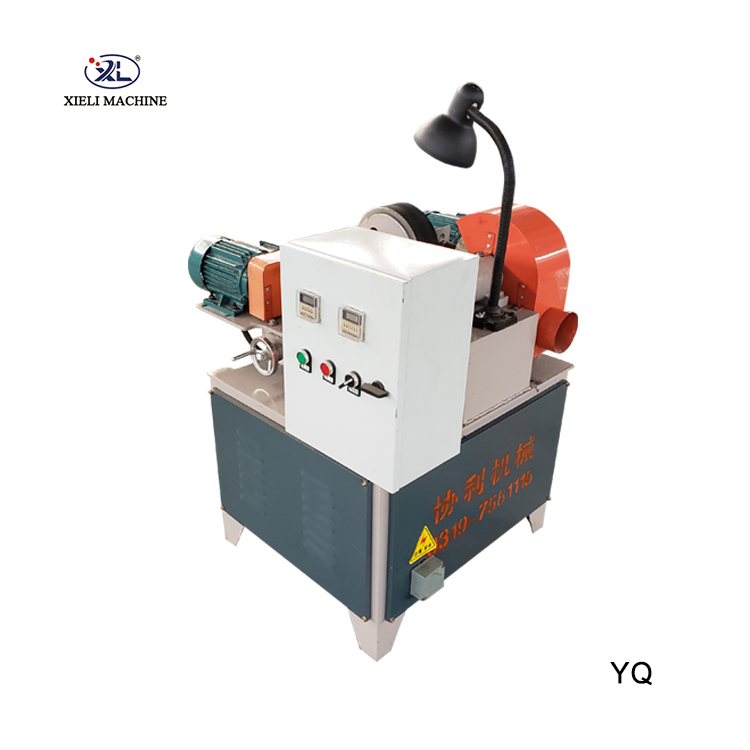

cincinnati twin grip centerless grinder service

Trustworthiness is perhaps the most significant factor when engaging a service firm. Trust is built through transparent communication, fair pricing, and reliable results. When your production is on the line, it is comforting to know that your service team views your success as their priority. This is evident in companies that offer flexible service plans, regular updates during repairs, and comprehensive post-service reports. By building long-term relationships with clients, these firms often provide discounts or priority service, underpinning their commitment to maintaining operational excellence.

Effective service doesn't just deal with current issues; it considers future challenges your Cincinnati Twin Grip might face. Up-to-date knowledge of the latest technological advancements and updates is crucial as CNC technology evolves. A forward-thinking service provider will incorporate the latest techniques in preventative maintenance schedules and align their services to match the advances in machine tools.

Investing in regular service for your Cincinnati Twin Grip Centerless Grinder is not merely a cost but a strategic investment in the longevity and accuracy of your operations. By focusing on experience, expertise, authoritativeness, and trustworthiness, you ensure that your machines are not just operational but at the cutting edge of performance and reliability. The right service provider acts as a partner to your business, ensuring that your production lines remain efficient, your products meet quality standards, and your company's reputation for excellence remains untarnished. So, choose wisely and invest in a service partner who understands the nuances of the Cincinnati Twin Grip and appreciates the value it adds to your operations.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.